Nissan Cube. Manual - part 397

EC-474

< PRECAUTION >

[MR18DE]

PRECAUTIONS

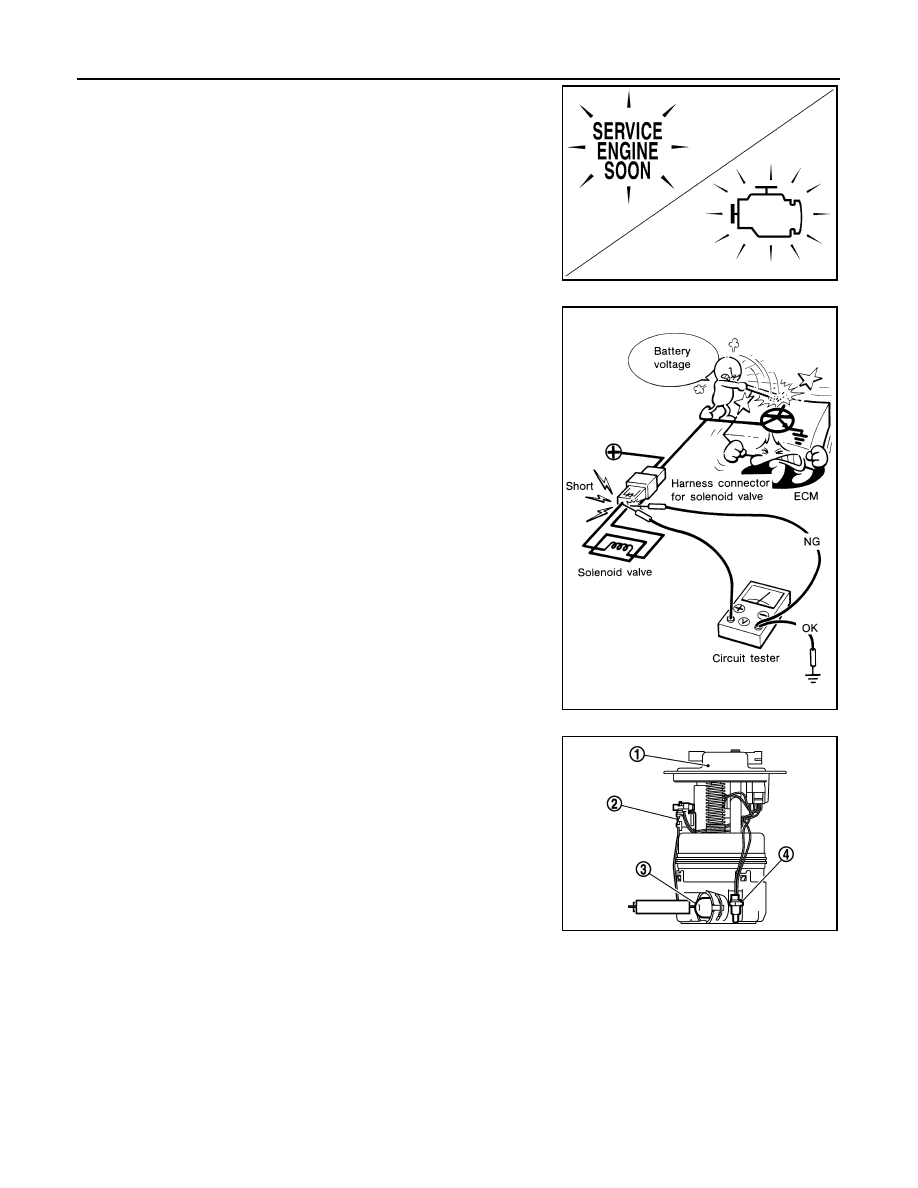

• After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir-

mation Procedure if the repair is completed. The Component

Function Check should be a good result if the repair is com-

pleted.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

JSBIA1315ZZ

SEF348N

JMBIA2316ZZ