Nissan Cube. Manual - part 379

EC-402

< DTC/CIRCUIT DIAGNOSIS >

[MR18DE]

COOLING FAN

COOLING FAN

Description

INFOID:0000000009947544

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 3-step control [HIGH/LOW/OFF].

COOLING FAN MOTOR

Models without A/C

The cooling fan operates at each speed when the current flows in the cooling fan motor as per the following.

Models with A/C

The cooling fan operates at high (HI) speed when the current flows, and operates at low (LOW) speed when

cooling fan motor and the resistor are circuited in series.

Component Function Check

INFOID:0000000009947545

1.

CHECK COOLING FAN FUNCTION

With CONSULT

1.

Turn ignition switch ON.

2.

Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT.

3.

Touch “LOW” and “Hi” on the CONSULT screen.

4.

Check that cooling fan operates at each speed.

Without CONSULT

1.

Perform IPDM E/R auto active test and check cooling fan motor operation. Refer to

or

PCS-41, "Diagnosis Description"

.

2.

Check that cooling fan operates at each speed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Refer to

.

Diagnosis Procedure

INFOID:0000000009947546

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E21. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK COOLING FAN MOTOR CIRCUIT

1.

Disconnect cooling fan motor harness connector.

2.

Check the continuity between IPDM E/R harness connector and cooling fan motor harness connector.

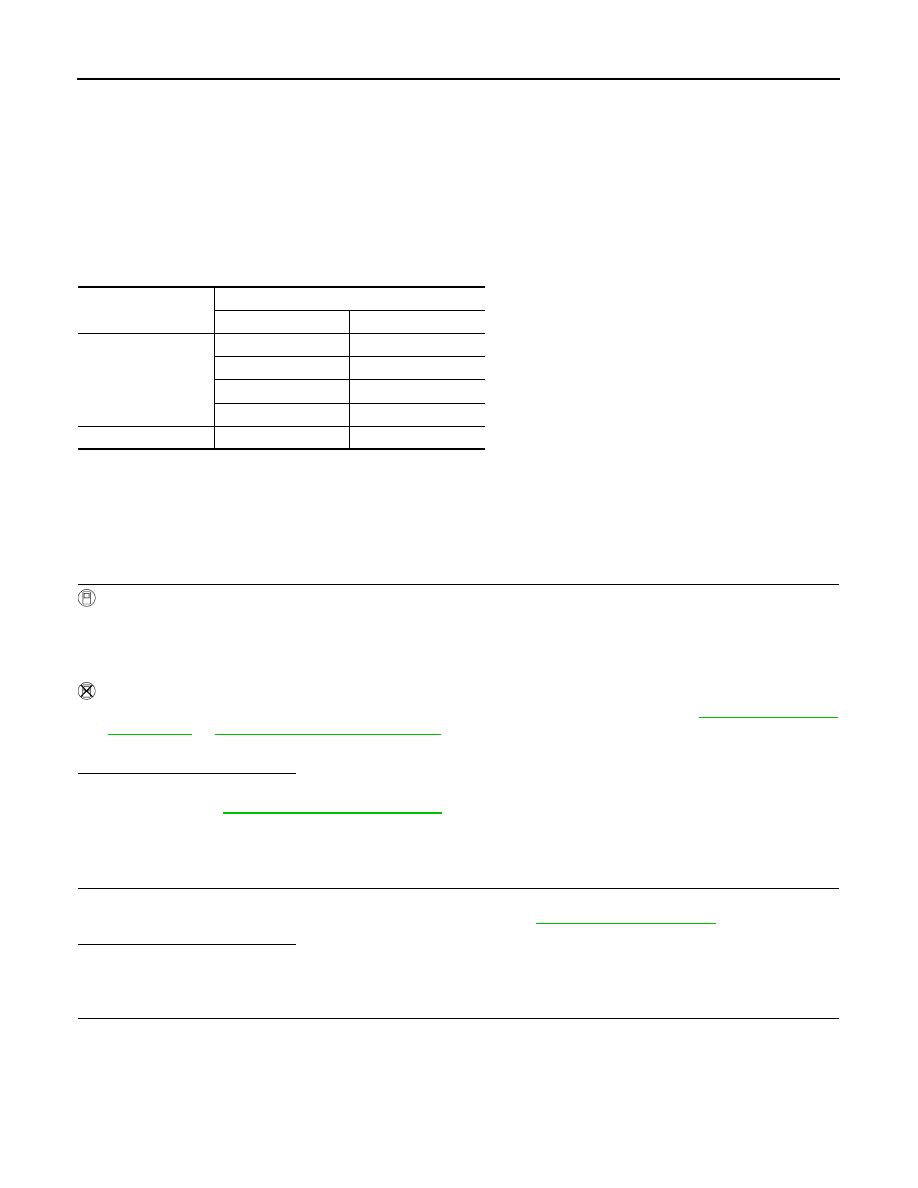

Cooling fan Speed

Cooling fan motor terminals

(+)

(–)

Low (LOW)

1

3 and 4

2

3 and 4

1 and 2

3

1 and 2

4

High (HI)

1 and 2

3 and 4