Nissan Cube. Manual - part 377

EC-394

< DTC/CIRCUIT DIAGNOSIS >

[MR18DE]

P2138 APP SENSOR

Diagnosis Procedure

INFOID:0000000009947533

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E38. Refer to

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

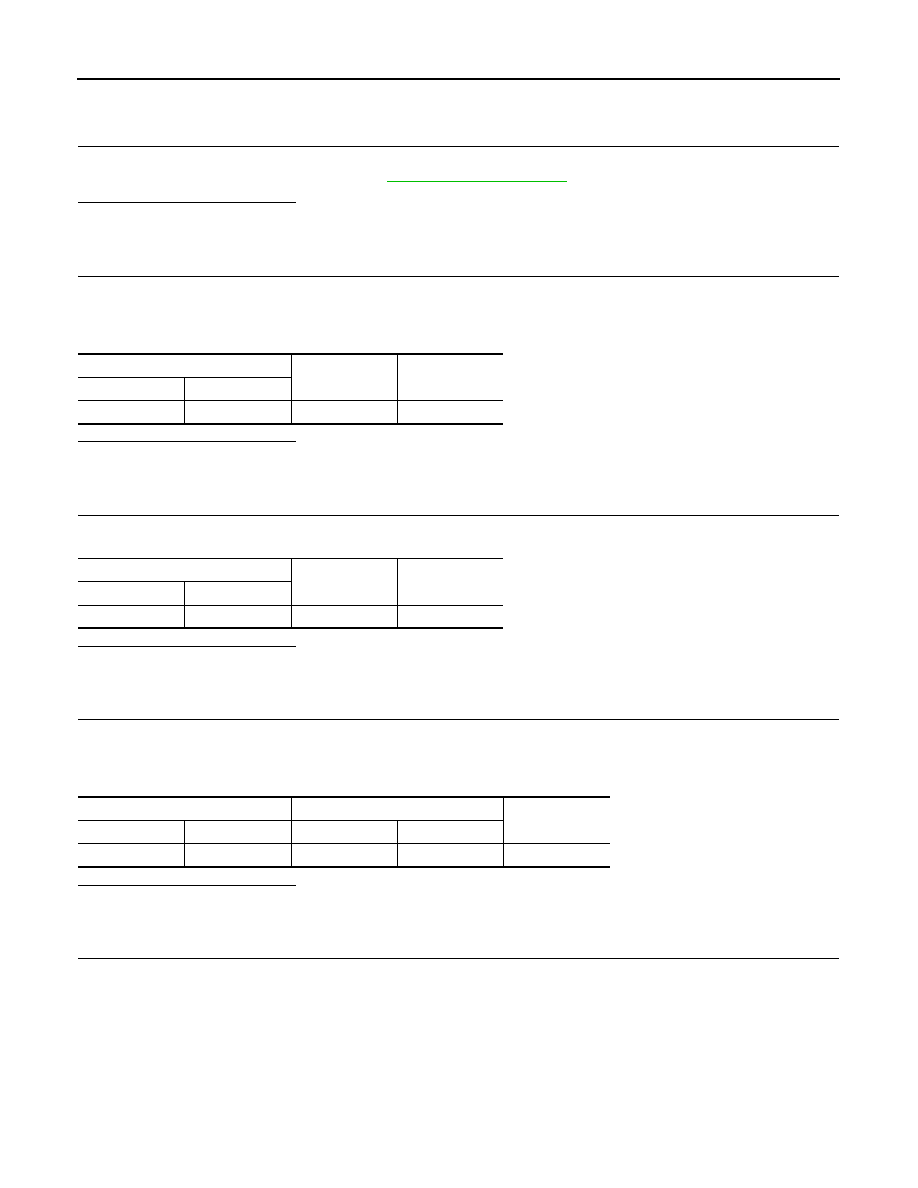

CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT

1.

Disconnect accelerator pedal position (APP) sensor harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between APP sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or short to ground or shot to power in harness or connectors.

3.

CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-I

1.

Check the voltage between APP sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> GO TO 4.

4.

CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between APP sensor harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or shot to power in harness or connectors.

5.

CHECK SENSOR POWER SUPPLY CIRCUIT

Check harness for short to power and short to ground, between the following terminals.

APP sensor

Ground

Voltage

Connector

Terminal

E110

4

Ground

Approx. 5 V

APP sensor

Ground

Voltage

Connector

Terminal

E110

5

Ground

Approx. 5 V

APP sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

E110

4

E16

106

Existed