Nissan Cube. Manual - part 145

CLUTCH MASTER CYLINDER

CL-13

< REMOVAL AND INSTALLATION >

C

E

F

G

H

I

J

K

L

M

A

B

CL

N

O

P

CLUTCH MASTER CYLINDER

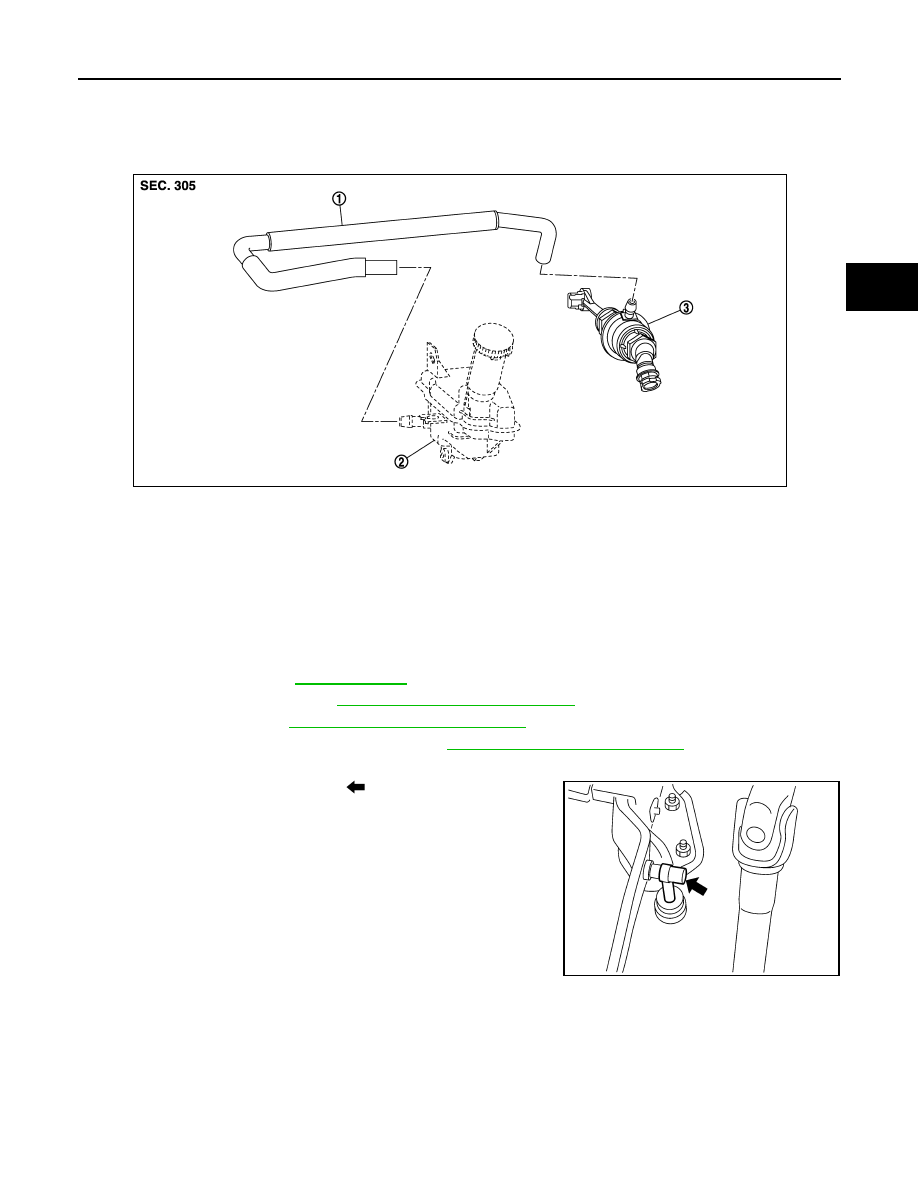

Exploded View

INFOID:0000000009949671

Removal and Installation

INFOID:0000000009949672

REMOVAL

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

• Never disassemble master cylinder.

1.

Drain clutch fluid. Refer to

.

2.

Remove air duct (inlet). Refer to

EM-24, "Removal and Installation"

3.

Remove battery. Refer to

PG-82, "Removal and Installation"

4.

Remove air cleaner case and air ducts. Refer to

EM-24, "Removal and Installation"

.

5.

Remove hose from reservoir tank assembly and master cylinder.

6.

Remove master cylinder rod end (

) from clutch pedal.

1.

Hose

2.

Reservoir tank assembly

3.

Master cylinder

JPDIB0162ZZ

PCIB1491E