Nissan Versa Note. Manual - part 574

MA-32

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

GEAR OIL : Refilling

INFOID:0000000009681961

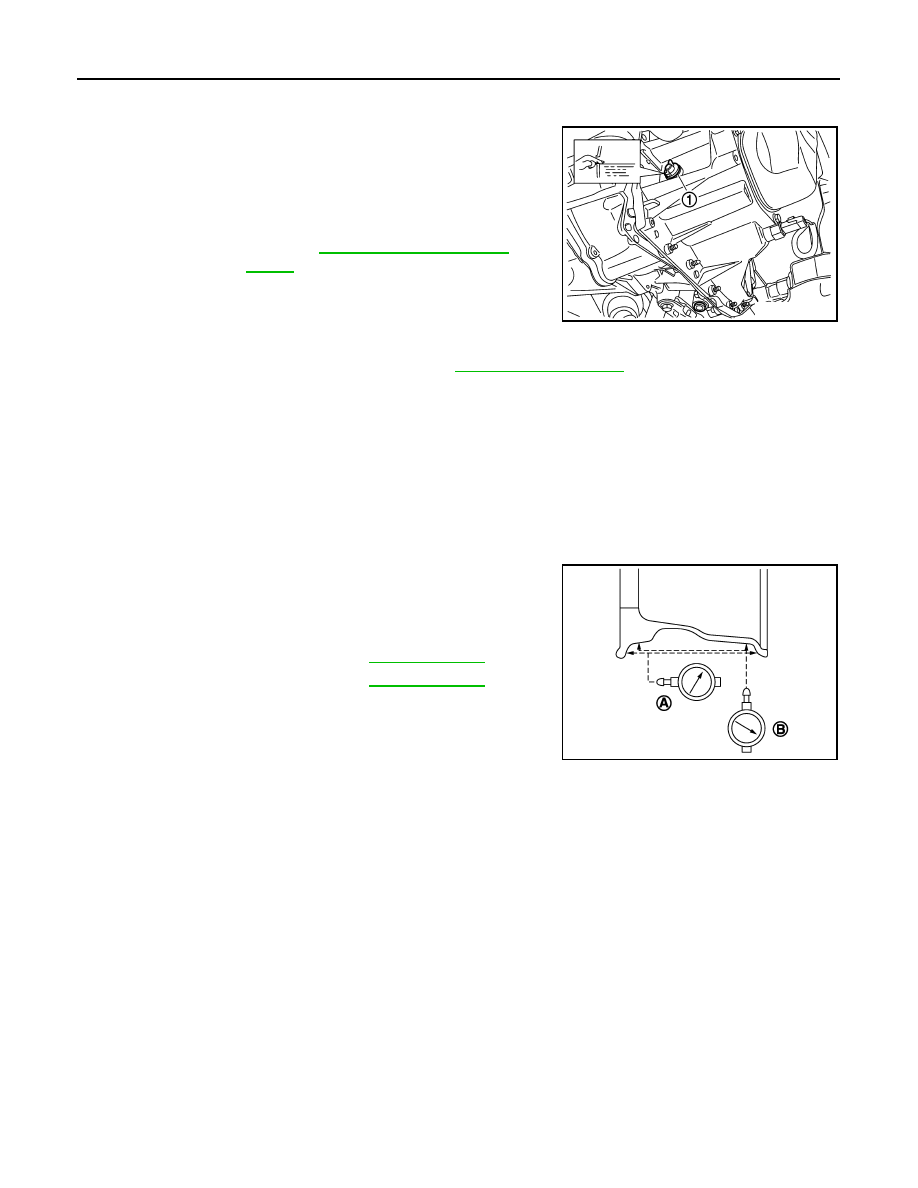

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until gear oil level reaches the specified

limit at filler plug hole as shown.

CAUTION:

Do not start engine while checking gear oil level.

3. Install a new gasket on filler plug and then install filler plug to

transaxle case.

CAUTION:

Do not reuse gasket.

4. Tighten filler plug to the specified torque. Refer to

WHEELS

WHEELS : Inspection

INFOID:0000000009681967

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from wheel and mount wheel on a balancer machine.

b. Set dial indicator as shown.

c.

Check runout, if runout value exceeds the limit, replace wheel.

WHEELS : Adjustment

INFOID:0000000009681968

BALANCING WHEELS (ADHESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the wheel and tire. Using releasing agent, remove double-faced

adhesive tape from the wheel and tire.

CAUTION:

• Be careful not to scratch the wheel and tire during removal.

• After removing double-faced adhesive tape, wipe clean all traces of releasing agent from the wheel

and tire.

Wheel Balance Adjustment

CAUTION:

• DO NOT use center hole cone-type clamping machines to hold the wheel during tire removal/installa-

tion or balancing or damage to the wheel paint, cladding or chrome may result. Use only rim-type or

universal lug-type clamping machines to hold the wheel during servicing.

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and

skip Step 2 below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2

to calculate the correct size adhesive weight.

1. Set wheel and tire on balancer machine using the center hole as a guide. Start the balancer machine.

Oil capacity

and viscosity

: Refer to

SCIA7119E

Limit

Axial Runout (A)

Refer to

.

Radial Runout (B)

.

SEIA0737E