Nissan Versa Note. Manual - part 445

FRONT WHEEL HUB AND KNUCKLE

FAX-7

< PERIODIC MAINTENANCE >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

PERIODIC MAINTENANCE

FRONT WHEEL HUB AND KNUCKLE

Inspection

INFOID:0000000009521209

COMPONENT PART

• Check that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

• Check the axle and suspension parts for excessive play, weary or damage.

• Shake each front wheel to check for excessive play.

FRONT WHEEL BEARING INSPECTION

Check the following items, and replace the part if necessary.

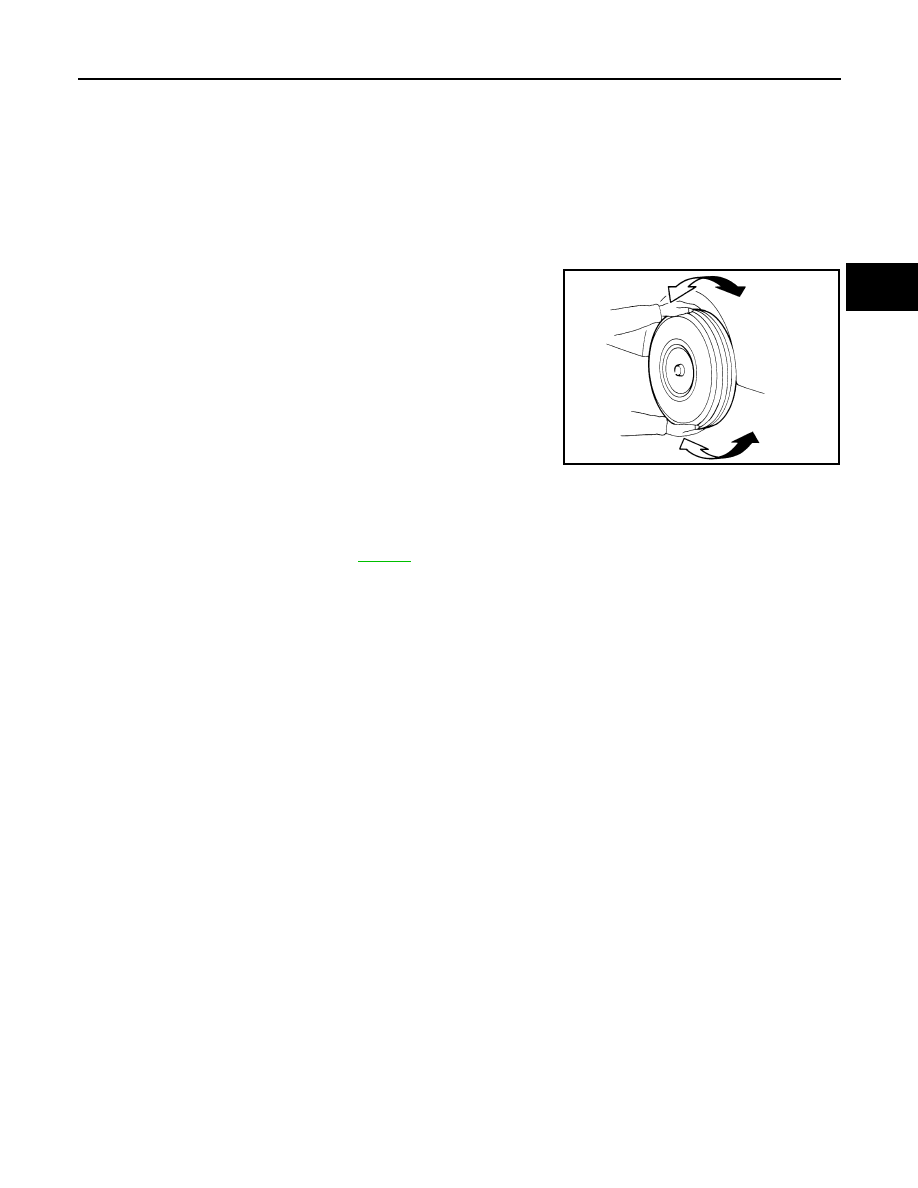

• Move the wheel bearing in the axial direction by hand. Make sure there is no looseness in the wheel bearing.

• Rotate the wheel bearing and make sure there is no unusual noise or other irregular conditions. If there are

any irregular conditions, replace wheel bearing.

SMA525A

Axial end play

: Refer to

.