Nissan Versa Note. Manual - part 167

COOLING FAN

CO-17

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

COOLING FAN

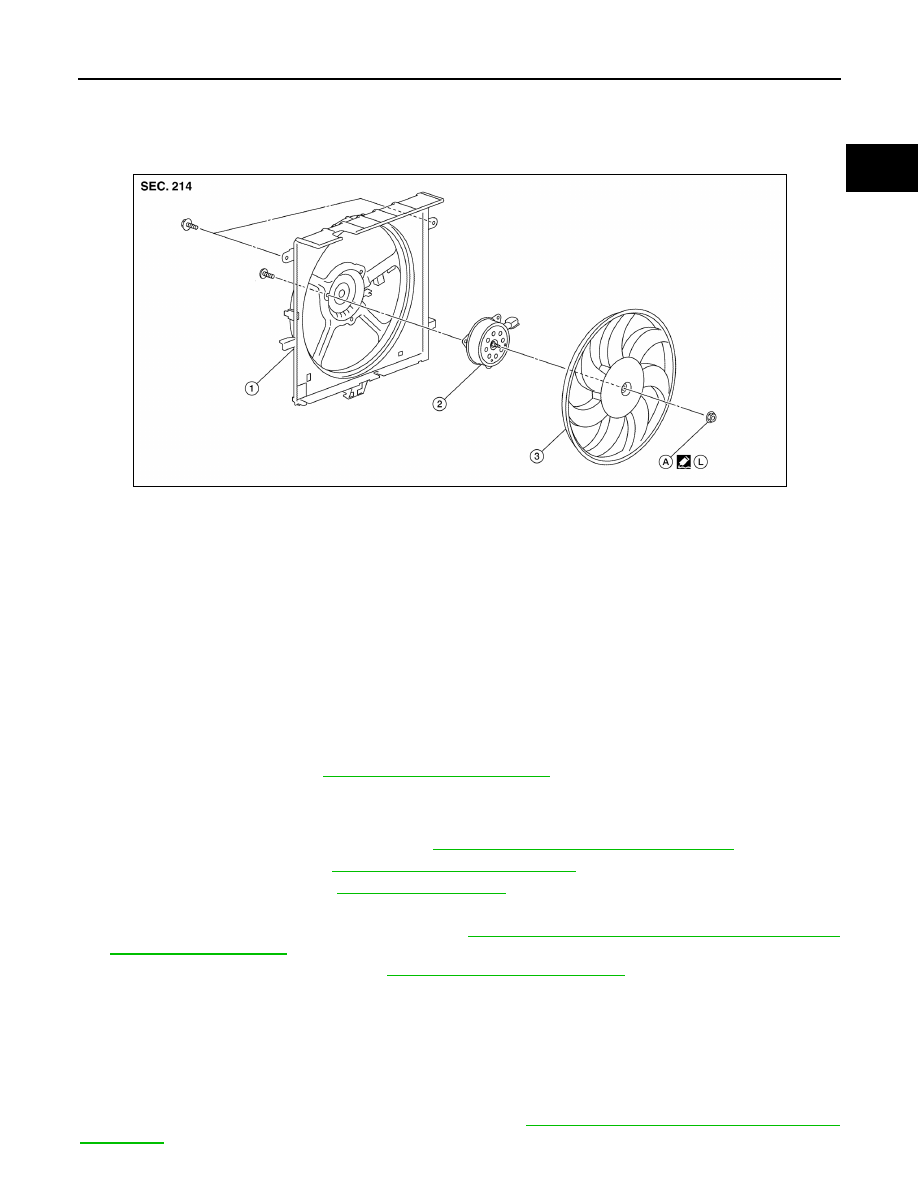

Exploded View

INFOID:0000000009444799

Removal and Installation

INFOID:0000000009444800

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the radiator cap. Slowly turn it a

quarter of a turn to release built-up pressure. Carefully remove radiator cap by turning it all the way.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

1. Drain engine coolant. Refer to

CO-8, "Draining Engine Coolant"

.

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belt.

2. Disconnect battery negative terminal. Refer to

PG-67, "Removal and Installation (Battery)"

.

3. Remove the front grille. Refer to

EXT-29, "Removal and Installation"

.

4. Remove reservoir tank. Refer to

.

5. Disconnect harness connector from fan motor, and move harness aside.

6. Remove radiator core support (upper). Refer to

DLK-139, "RADIATOR CORE SUPPORT UPPER :

.

7. Remove cooling fan assembly. Refer to

CO-17, "Removal and Installation"

CAUTION:

Be careful not to damage or scratch the radiator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Only use Genuine NISSAN parts for the fan shroud bolt.

NOTE:

Cooling fan assembly is controlled by ECM. For details, refer to

EC-38, "COOLING FAN CONTROL : System

.

1.

Fan shroud

2.

Fan motor

3.

Cooling fan

A.

Cooling fan nut

L.

Genuine NISSAN high strength lock-

ing sealant

AWBIA1140GB