Nissan Versa Note. Manual - part 165

ENGINE COOLANT

CO-9

< PERIODIC MAINTENANCE >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

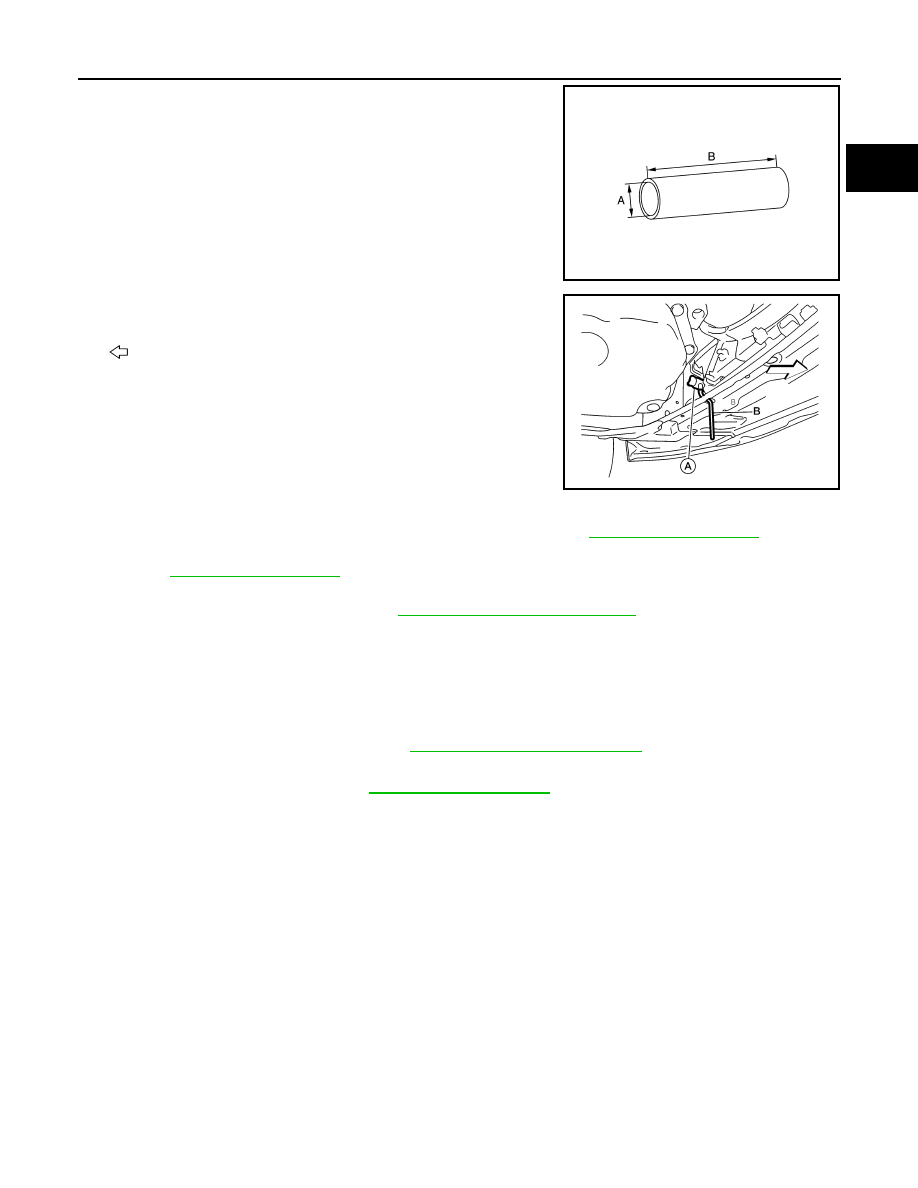

2. Connect a suitable hose to the radiator drain plug.

• Use a suitable hose with the dimensions as shown.

3. Open radiator drain plug (A) at the bottom of radiator, and then

remove radiator cap.

(B): Suitable hose

: Front

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on the drive belt.

4. It is necessary to drain the cylinder block when draining all of engine coolant in the system. To drain the

cylinder block, open the water drain plugs on cylinder block. Refer to

5. Remove reservoir tank if necessary, and drain engine coolant and clean reservoir tank before installing.

6. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated,

flush the engine cooling system. Refer to

CO-11, "Flushing Cooling System"

.

Refilling

INFOID:0000000009509399

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of engine coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance

Thread Sealant or equivalent. Refer to

MA-11, "Fluids and Lubricants"

.

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heater ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

Diameter (A)

: 0.8 mm (0.31 in)

Length (B)

: 300 mm (11.81 in)

JPBIA4770ZZ

AWBIA1613ZZ

Radiator drain plug

: Refer to