Nissan Versa Note. Manual - part 123

BRC-56

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C1101, C1102, C1103, C1104 WHEEL SENSOR

1. Disconnect ABS actuator and electric unit (control unit) connector E33 and wheel sensor connector of

suspect wheel.

2. Check harness, connectors and terminals for corrosion, deformation, disconnection, looseness or dam-

age.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace as necessary.

4.

CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch.

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash ON and OFF to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES

>> GO TO 5.

NO

>> Replace the wheel sensor. Refer to

BRC-105, "FRONT WHEEL SENSOR : Removal and Installa-

or

BRC-106, "REAR WHEEL SENSOR : Removal and Installation"

5.

CHECK WIRING HARNESS FOR SHORT TO VOLTAGE

1. Turn ignition switch ON.

2. Check voltage between wheel sensor harness connector terminals of suspect wheel and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair the circuit.

6.

CHECK WIRING HARNESS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Check continuity between wheel sensor harness connector terminals of suspect wheel and ground.

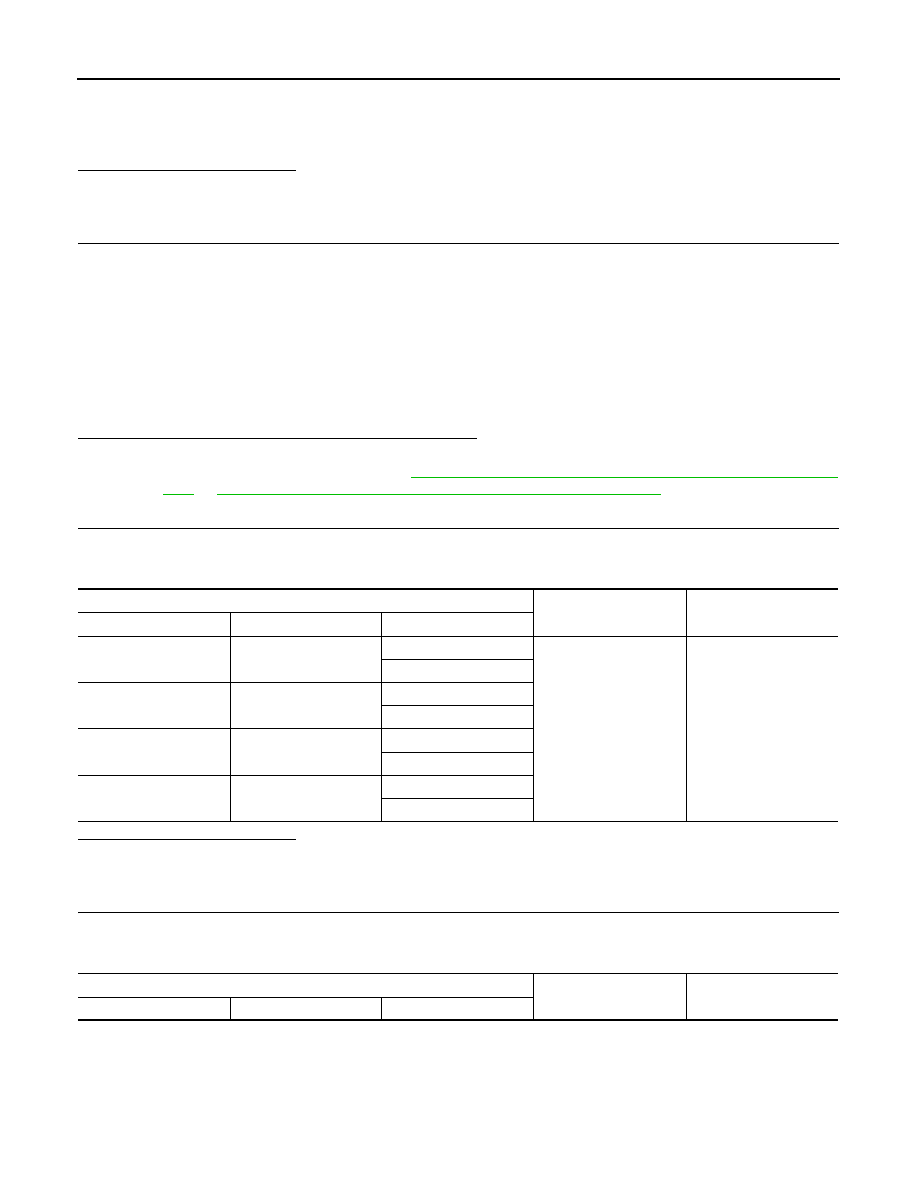

Wheel Sensor

Ground

Voltage

Wheel

Connector

Terminal

Front LH

E51

1

—

0V

2

Front RH

E52

1

2

Rear LH

B22

1

2

Rear RH

B35

1

2

Wheel Sensor

Ground

Continuity

Wheel

Connector

Terminal