Nissan Rogue. Manual - part 900

ENGINE MAINTENANCE

MA-15

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

1. Remove the drive belt. Refer to

MA-13, "DRIVE BELTS : Removal and Installation"

.

2. Remove the drive belt auto-tensioner.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Install the drive belt auto-tensioner carefully so not to damage the water pump pulley.

• If there is damage greater than peeled paint, replace the drive belt auto-tensioner.

AIR CLEANER FILTER

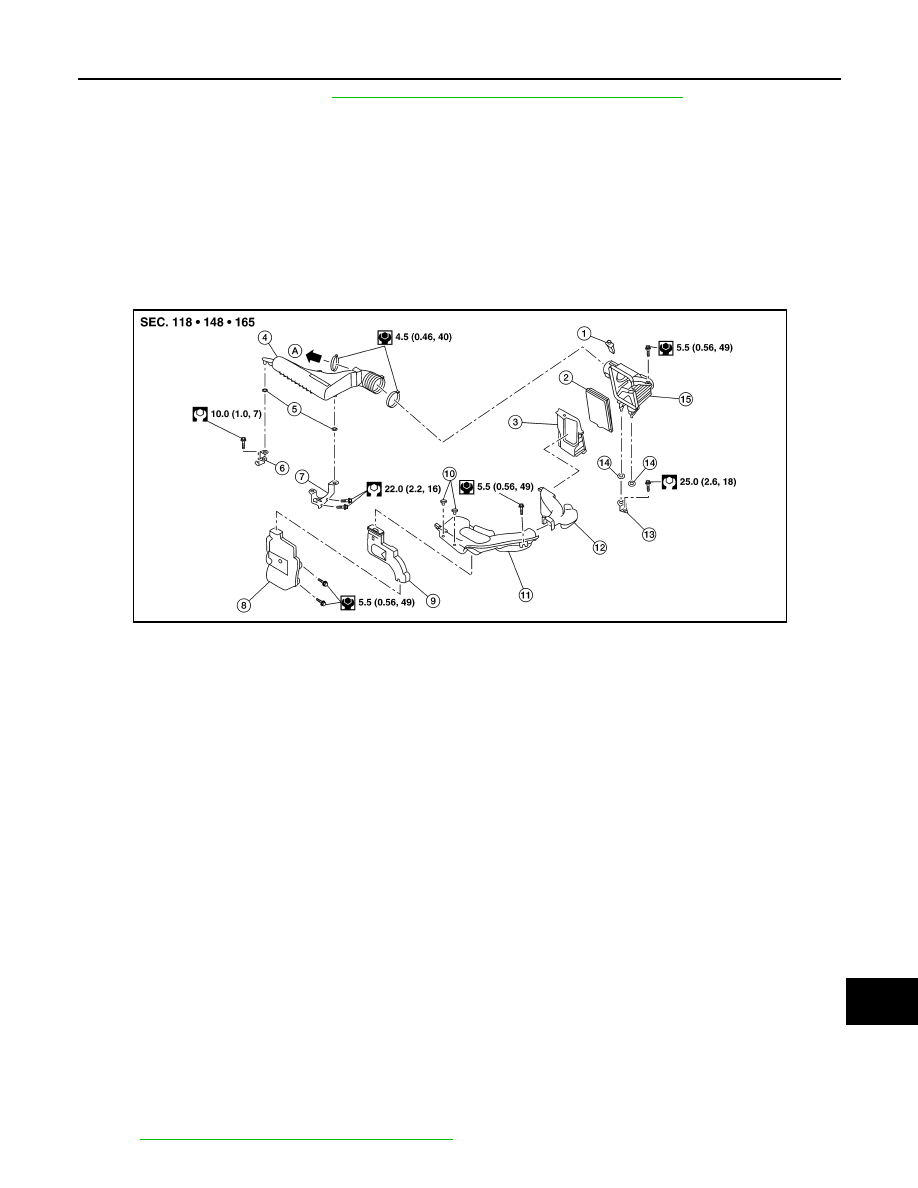

AIR CLEANER FILTER : Exploded View

INFOID:0000000011378298

AIR CLEANER FILTER : Removal and Installation

INFOID:0000000011378299

CHANGING THE AIR CLEANER FILTER

1. Remove air duct assembly from air cleaner case (upper).

2. Open the air cleaner case.

3. Remove the air cleaner filter.

4. Install a new air cleaner filter.

5. Close the air cleaner case.

6. Secure the air cleaner case clips.

INSPECTION AFTER REMOVAL

Examine the air cleaner filter for stains, clogging, or damage.

• Remove dirt and foreign objects (such as dead leaves) on air cleaner filter surface and inside cleaner case.

• If clogging or damage is observed, replace the air cleaner filter.

CAUTION:

Do not clean the viscous paper type air cleaner filter by blowing as there is a risk of deterioration of its

performance.

MAINTENANCE INTERVAL

MA-7, "Introduction of Periodic Maintenance"

1.

Mass air flow sensor

2.

Air cleaner filter

3.

Air cleaner case (lower)

4.

Air duct assembly

5.

Grommet

6.

Resonator bracket (front)

7.

Resonator bracket (rear)

8.

Resonator

9.

Air duct

10.

Mounting clip

11.

Air duct assembly

12.

Air duct assembly

13.

Air cleaner bracket

14.

Grommet

15.

Air cleaner case (upper)

A.

To Electric throttle control actuator

AWBIA2261ZZ