Nissan Rogue. Manual - part 774

HAC-118

< SYSTEM DESCRIPTION >

[MANUAL AIR CONDITIONING]

SYSTEM

SYSTEM

System Description

INFOID:0000000011276666

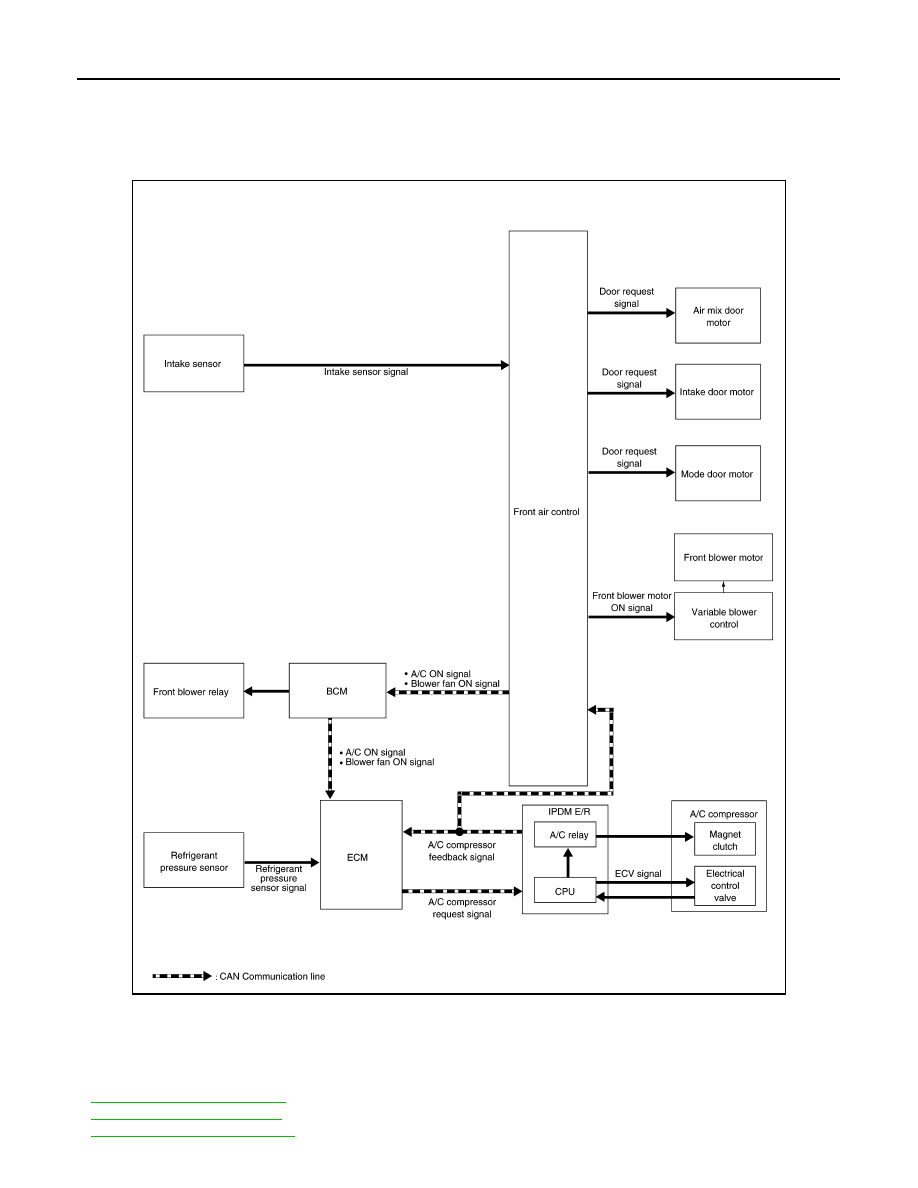

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• The manual air conditioning system is controlled by a sequence of functions from the front air control, BCM,

ECM, and IPDM E/R.

Controlled by front air control:

-

-

-

ALIIA0909GB