Nissan Rogue. Manual - part 744

HA-44

< REMOVAL AND INSTALLATION >

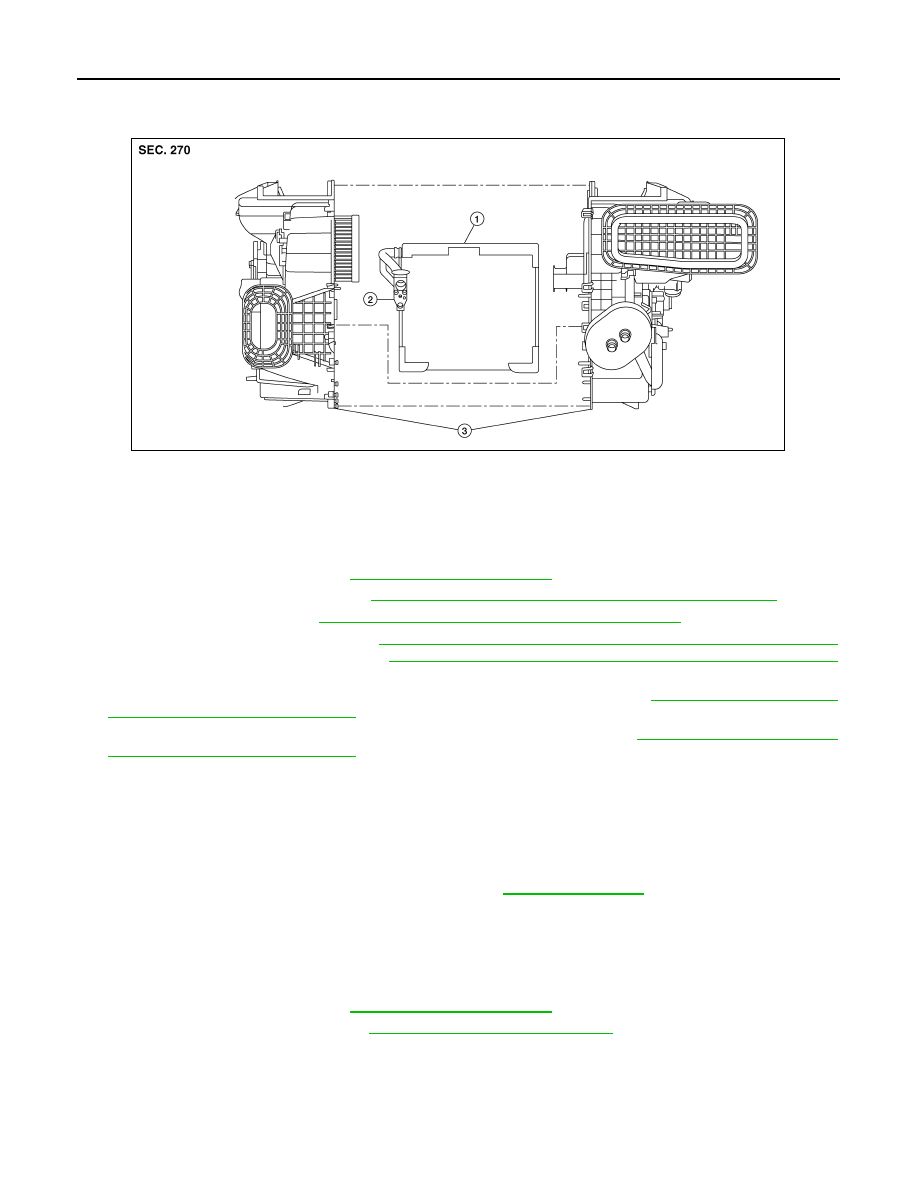

HEATING AND COOLING UNIT ASSEMBLY

EVAPORATOR : Exploded View

INFOID:0000000011279506

EVAPORATOR : Removal and Installation

INFOID:0000000011279507

REMOVAL

1. Discharge the refrigerant. Refer to

2. Remove front foot duct (LH). Refer to

VTL-10, "FRONT FOOT DUCT : Removal and Installation"

3. Remove heater core. Refer to

HA-43, "HEATER CORE : Removal and Installation"

4. Remove intake door motor. Refer to

HAC-110, "INTAKE DOOR MOTOR : Removal and Installation"

(AUTOMATIC AIR CONDITIONING) or

HAC-186, "INTAKE DOOR MOTOR : Removal and Installation"

(MANUAL AIR CONDITIONING).

5. Remove air mix door motor (LH) (AUTOMATIC AIR CONDITONING). Refer to

MOTOR : Removal and Installation"

.

6. Remove air mix door motor (MANUAL AIR CONDITIONING). Refer to

MOTOR : Removal and Installation"

.

7. Separate the heating and cooling unit assembly and remove evaporator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply A/C oil to new O-rings for installation.

• After charging the refrigerant, check for leaks. Refer to

EXPANSION VALVE

EXPANSION VALVE : Removal and Installation

INFOID:0000000011279508

REMOVAL

1. Discharge the refrigerant. Refer to

2. Remove cowl top extension. Refer to

EXT-25, "Removal and Installation"

1.

Evaporator

2.

Expansion valve

3.

Heating and cooling unit assembly

ALIIA0945ZZ