Nissan Rogue. Manual - part 591

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-129

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Unit: mm (in)

UNDERSIZE

Unit: mm (in)

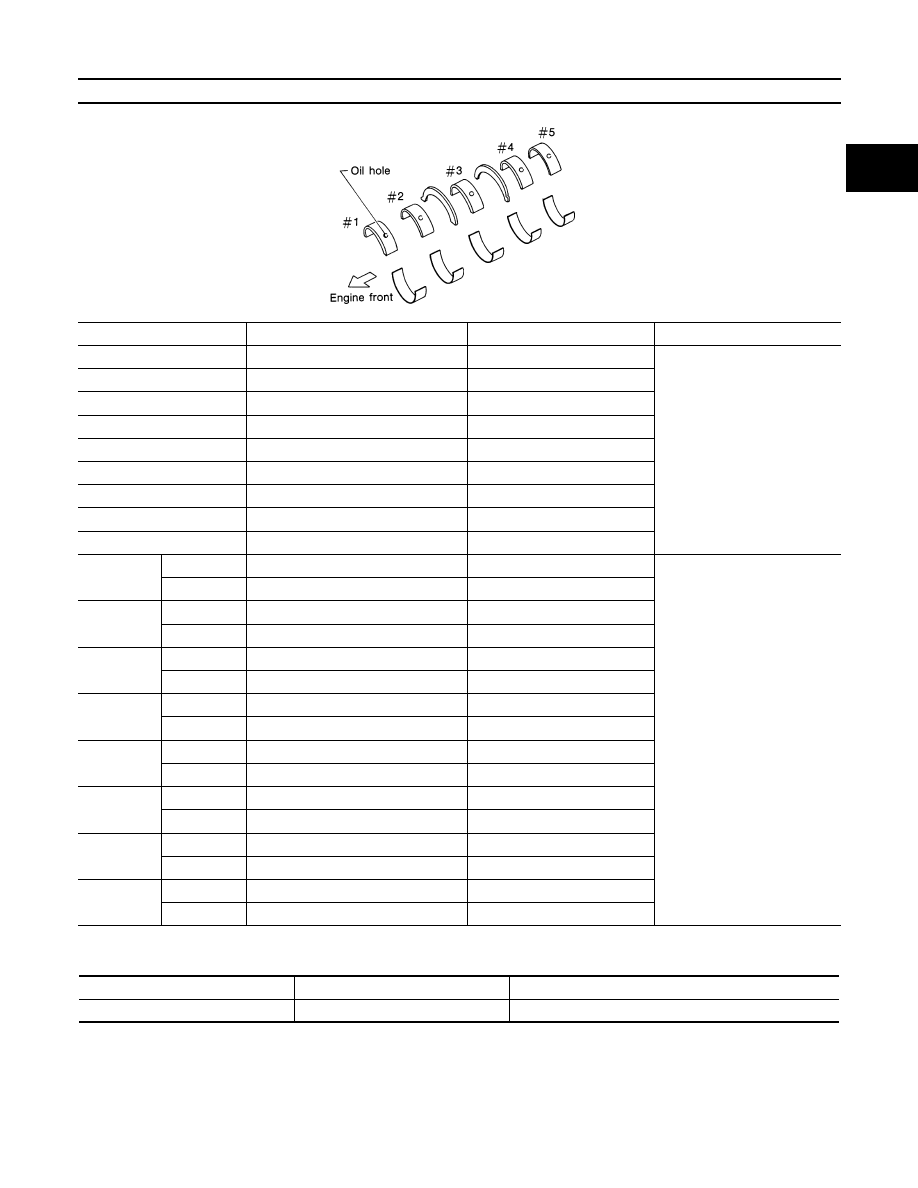

MAIN BEARING OIL CLEARANCE

Grade number

Thickness

Identification color

Remarks

-1

1.970 - 1.973 (0.0776 - 0.0777)

Red

Grade and color are the same

upper and lower bearings

0

1.973 - 1.976 (0.0777 - 0.0778)

Black

1

1.976 - 1.979 (0.0778 - 0.0779)

Brown

2

1.979 - 1.982 (0.0779 - 0.0780)

Green

3

1.982 - 1.985 (0.0780 - 0.0781)

Yellow

4

1.985 - 1.988 (0.0781 - 0.0783)

Blue

5

1.988 - 1.991 (0.0783 - 0.0784)

Pink

6

1.991 - 1.994 (0.0784 - 0.0785)

Purple

7

1.994 - 1.997 (0.0785 - 0.0786)

White

-10

UPR

1.970 - 1.973 (0.0776 - 0.0777)

Red

Grade and color are different

for upper and lower bearings

LWR

1.973 - 1.976 (0.0777 - 0.0778)

Black

01

UPR

1.973 - 1.976 (0.0777 - 0.0778)

Black

LWR

1.976 - 1.979 (0.0778 - 0.0779)

Brown

12

UPR

1.976 - 1.979 (0.0778 - 0.0779)

Brown

LWR

1.979 - 1.982 (0.0779 - 0.0780)

Green

23

UPR

1.979 - 1.982 (0.0779 - 0.0780)

Green

LWR

1.982 - 1.985 (0.0780 - 0.0781)

Yellow

34

UPR

1.982 - 1.985 (0.0780 - 0.0781)

Yellow

LWR

1.985 - 1.988 (0.0781 - 0.0783)

Blue

45

UPR

1.985 - 1.988 (0.0781 - 0.0783)

Blue

LWR

1.988 - 1.991 (0.0783 - 0.0784)

Pink

56

UPR

1.988 - 1.991 (0.0783 - 0.0784)

Pink

LWR

1.991 - 1.994 (0.0784 - 0.0785)

Purple

67

UPR

1.991 - 1.994 (0.0784 - 0.0785)

Purple

LWR

1.994 - 1.997 (0.0785 - 0.0786)

White

SEM685D

Items

Thickness

Main journal diameter

0.25 (0.0098)

2.106 - 2.114 (0.0829 - 0.0832)

Grind so that bearing clearance is the specified value.