Nissan Rogue. Manual - part 587

CYLINDER BLOCK

EM-113

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

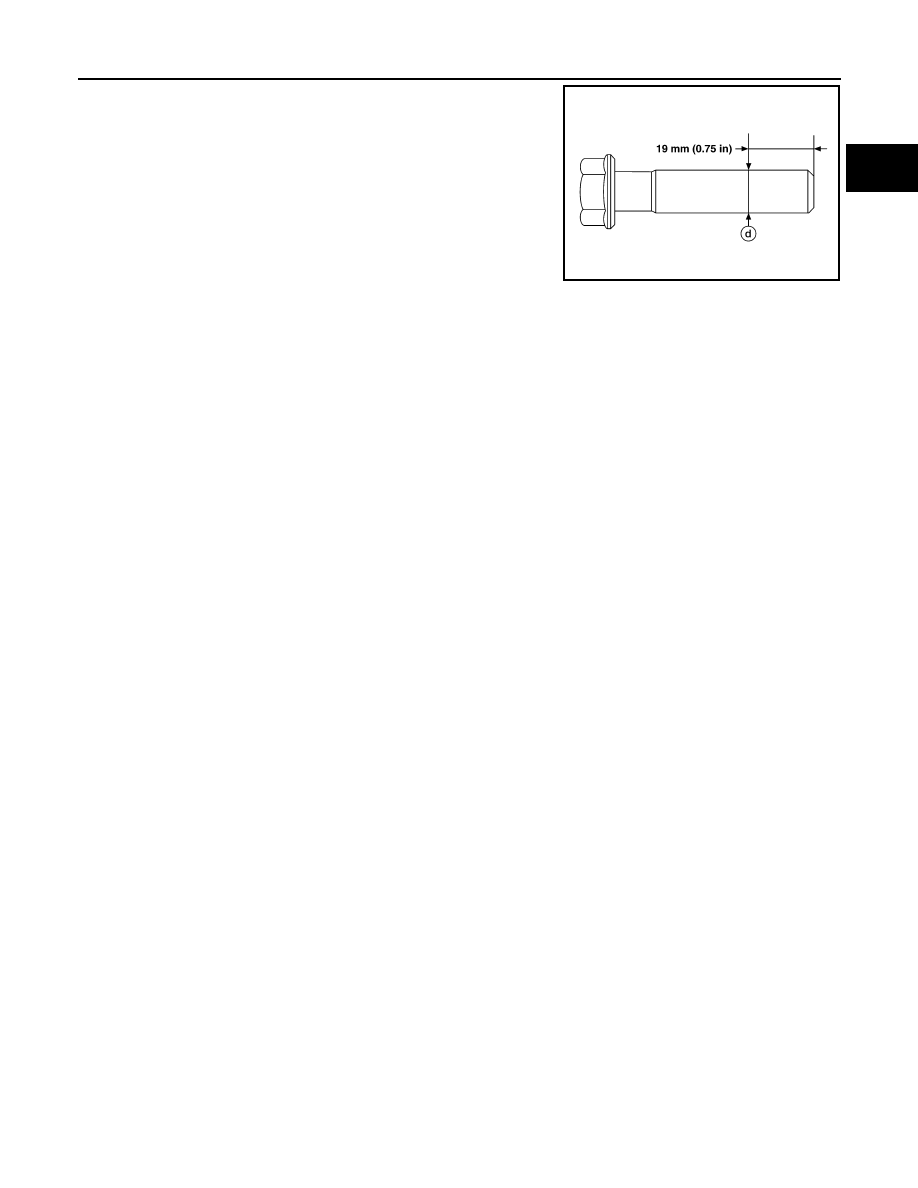

• Measure outer diameter (d) at position as shown.

• If reduction appears in position other than (d), regard it as (d).

• If measured value exceeds limit (large difference in dimensions)

replace connecting rod bolt with new one.

Limit: 7.75 mm (0.3051 in)

AWBIA1944ZZ