Nissan Rogue. Manual - part 578

CAMSHAFT

EM-77

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

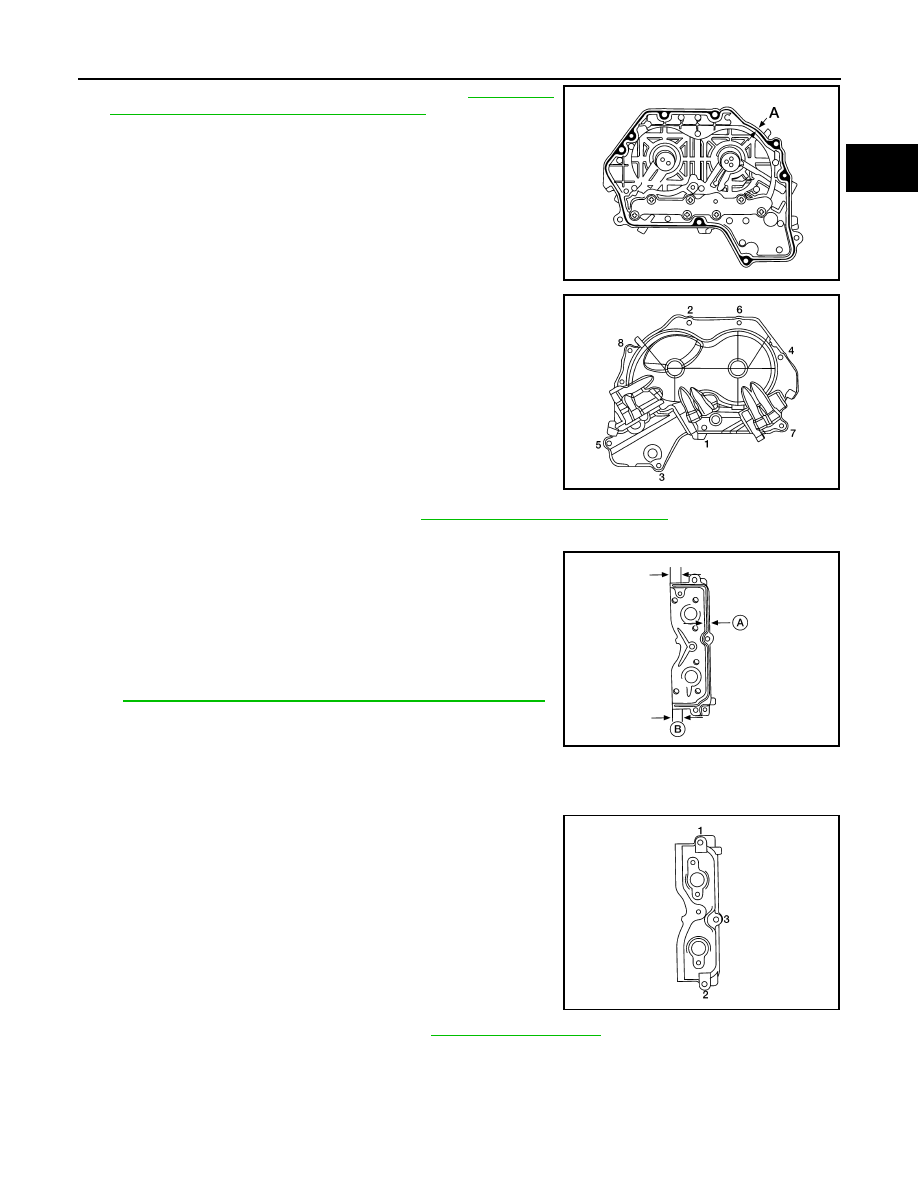

c. Apply liquid gasket to the positions shown. Refer to

ommended Chemical Products and Sealants"

d. Install valve timing control cover.

• Tighten the bolts to specification in the numerical order as

shown.

9. Check and adjust valve clearances. Refer to

EM-21, "Camshaft valve clearance"

10. Install camshaft position sensor bracket.

a. Apply liquid gasket to camshaft position sensor bracket as

shown.

CAUTION:

• Use Genuine Silicone RTV Sealant, or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

• After installation be sure to wipe off excessive liquid gas-

ket leaking from part (B).

• Installation should be done within 5 minutes after apply-

ing liquid gasket.

• Do not fill the engine with engine oil for at least 30 minutes after the components are installed to

allow the liquid gasket to cure.

b. Tighten bolts to specification in numerical order shown.

11. Install the camshaft position sensors. Refer to

.

12. Installation of the remaining components is in the reverse order of removal.

Inspection After Installation

INFOID:0000000011279968

Inspection of Camshaft Sprocket (INT) Oil Groove and Camshaft Sprocket (EXH) Oil Groove

Diameter (A)

: 3.4 - 4.4 mm (0.134 - 0.173 in)

AWBIA1362ZZ

ALBIA0839GB

(A) : 2.0 - 3.0 mm (0.079-0.118)

(B) : 10.5 mm (0.413 in)

Camshaft position

sensor bracket bolts

: 10.41 N·m (1.1 kg-m, 8 ft-lb)

ALBIA0907GB

ALBIA0908GB