Nissan Rogue. Manual - part 560

PRECAUTIONS

EM-5

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

CAUTION:

• Use approved shatter-resistant eye protection when performing this procedure.

• Perform this and all subsequent disposal work procedures in an open room, away from flammable

liquids. Keep a fire extinguisher, rated at least 10 ABC, in close proximity to the work area.

• Be sure to wear rubber gloves when performing the following operations.

• Make sure the resultant (high alkalinity) waste water does not contact your skin. If the waste water

does contact you, wash the contacted area immediately with large quantities of water.

• Dealers should check their respective state and local regulations concerning any chemical treatment

or waste water discharge permits which may be required to dispose of the resultant (high alkalinity)

waste water.

1. Clamp valve stem in a vice.

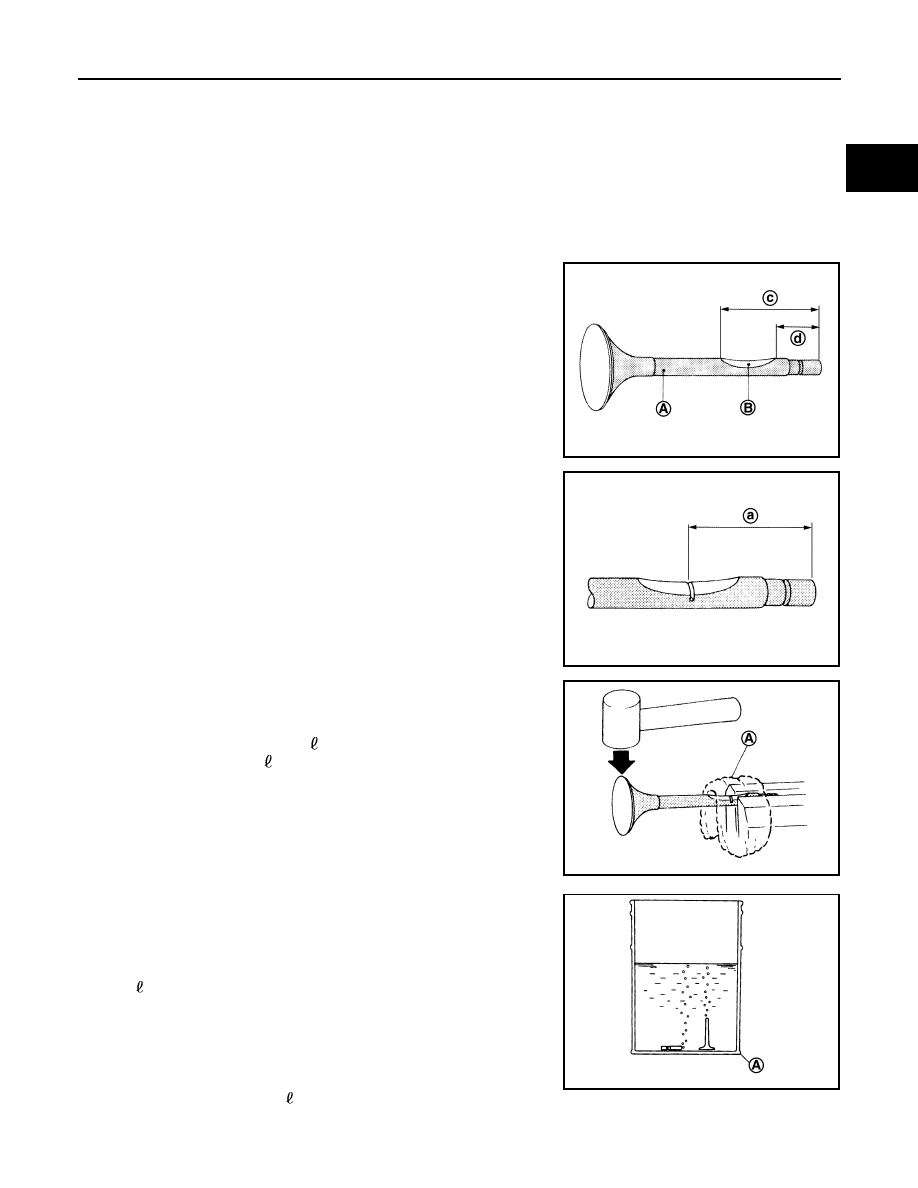

2. The valve has a specially-hardened surface. To cut through it,

first remove a half-round section, approximately 30 mm (1.18 in)

long using air-powered grinder until black color is removed and

silver color appears.

3. Use hacksaw to cut through approximately half the diameter of

valve stem. Make the serration at a point 40 mm (1.57 in) from

the end of valve stem.

4. Cover the serrated end of the valve with a large shop towel (A).

Strike the valve face end with a hammer, separating it into two

pieces.

5. Fill a bucket, such as a 20 (5-1/4 US gal, 4-3/8 Imp gal) oil

can, with at least 10 (2-5/8 US gal, 2-1/4 lmp gal) of water.

Carefully place the already cut (serrated) valves into the water

one-at-a-time using a set of large tweezers and quickly move

away at least 2.7 m (9 ft).

6. The valves should be placed in a standing position as shown in

the illustration to allow complete reaction. After the bubbling

action has subsided, additional valves can be placed into the

bucket allowing each subsequent chemical reaction to subside.

However, no more than 8 valves should be placed in the same

10 (2-5/8 US gal, 2-1/4 lmp gal) amount of water. The com-

plete chemical reaction may take as long as 4 to 5 hours.

Remove the valves using a set of large tweezers after the chem-

ical reaction has stopped. Afterwards, valves can be disposed

as ordinary scrap.

(A)

: Black color

(B)

: Silver color

(c)

: 47 mm (1.85 in)

(d)

: 17 mm (0.67 in)

JPBIA4964ZZ

(a)

: 40 mm (1.57 in)

JPBIA4965ZZ

JPBIA4966ZZ

A

: Bucket [Such as 20 (5-1/4 US gal, 4-3/8 Imp gal) oil can]

JPBIA4967ZZ