Nissan Rogue. Manual - part 540

EC-428

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

P2014, P2016, P2017, P2018 INTAKE MANIFOLD RUNNER CONTROL VALVE

POSITION SENSOR

NO

>> Repair or replace error-detected parts.

5.

CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between intake manifold runner control valve position sensor harness connector and

ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace error-detected parts.

6.

CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between intake manifold runner control valve position sensor harness connector and

ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair or replace error-detected parts.

7.

CHECK INTERMITTENT INCIDENT

Perform

GI-44, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace intake manifold assembly. Refer to

EM-29, "Removal and Installation"

NO

>> Repair or replace error-detected parts.

8.

CHECK INTERMITTENT INCIDENT

GI-44, "Intermittent Incident"

>> INSPECTION END

+

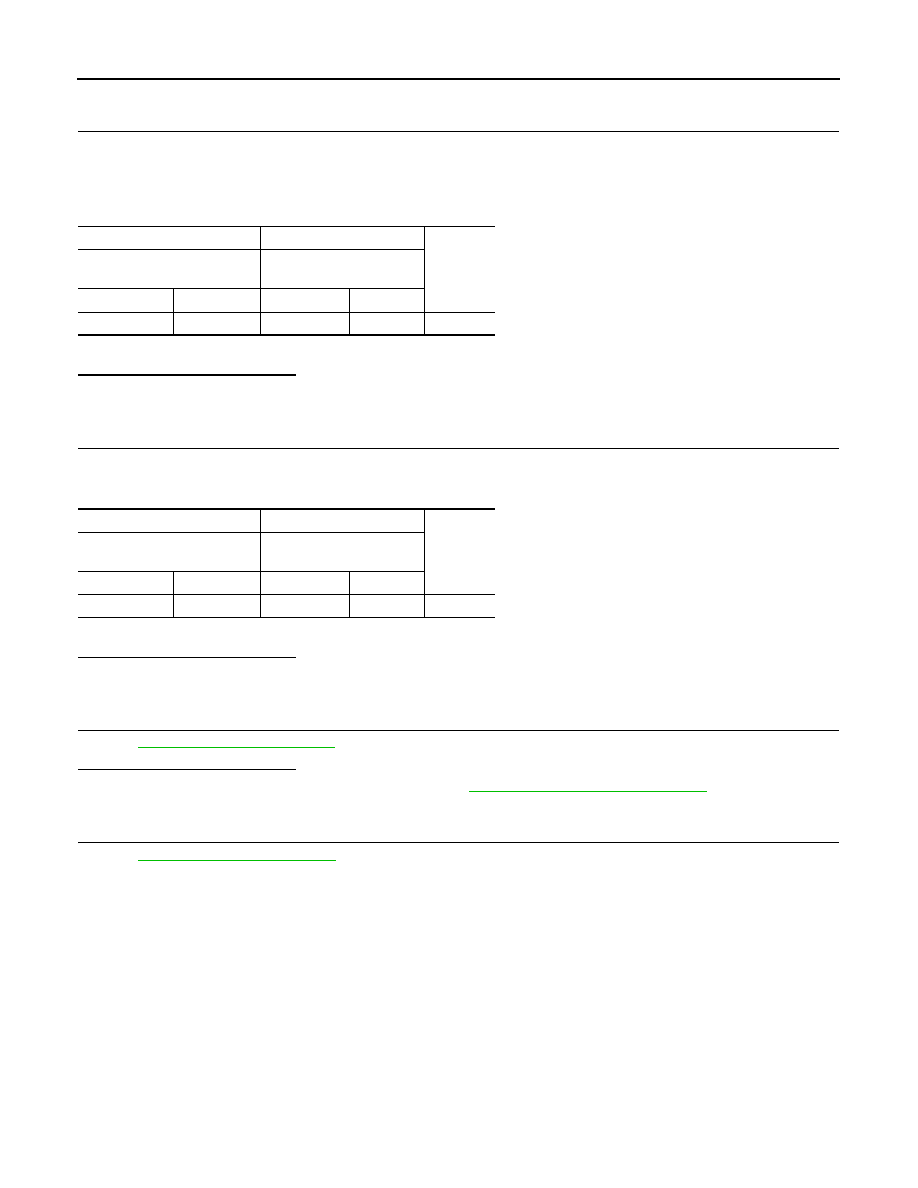

-

Continuity

Intake manifold runner control

valve position sensor

ECM

Connector

Terminal

Connector

Terminal

F20

3

F52

92

Existed

+

-

Continuity

Intake manifold runner control

valve position sensor

ECM

Connector

Terminal

Connector

Terminal

F20

2

F52

83

Existed