Nissan Rogue. Manual - part 444

EC-44

< SYSTEM DESCRIPTION >

[QR25DE]

SYSTEM

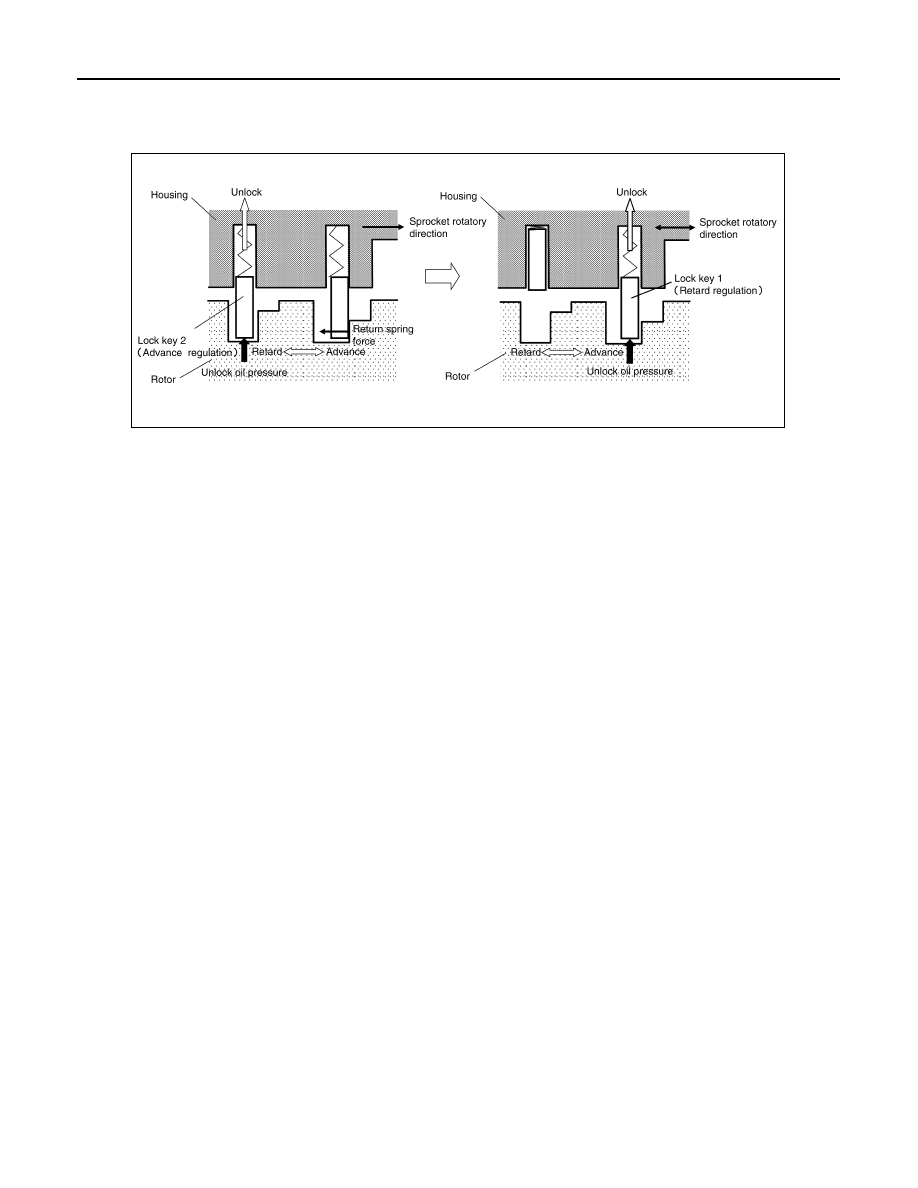

this reason, lock key 2 is released first by being pushed up by unlocking oil pressure. When lock key 2 is

released, some clearance is formed between lock key 1 and the rotor due to sprocket rotational force and

return spring force. Accordingly, lock key 1 is pushed up by unlocking oil pressure and the intermediated

phase lock is released.

When stopping the engine

When the ignition switch is turned from idle state to OFF, ECM receives an ignition switch signal from BCM via

CAN communication and activates the intake valve timing intermediate lock control solenoid valve and drains

oil pressure acting on the lock key before activating the intake valve timing control solenoid valve and operat-

ing the cam phase toward the advance position.

The cam phase is fixed by the lock key when shifting to the intermediated phase and ECM performs Lock

judgment to stop the engine.

When starting the engine

When starting the engine by cold start, ECM judges the locked/unlocked state when ignition switch is turned

ON. When judged as locked state (fixed at the intermediate phase), the intake valve timing intermediate lock

control solenoid valve is activated. Since oil pressure does not act on the lock key even when the engine is

started, the cam phase is fixed at the intermediate phase and the intake valve timing control is not performed.

When the engine stops without locking the cam phase at the intermediate phase due to an engine stall and the

state is not judged as locked, the intake valve timing intermediate lock control solenoid valve and the intake

valve timing control solenoid valve are activated and the cam phase shifts to the advanced position to be

locked at the intermediate phase. Even when not locked in the intermediate lock phase due to no oil pressure

or low oil pressure, a ratchet structure of the camshaft sprocket (INT) rotor allows the conversion to the inter-

mediate phase in stages by engine vibration.

When engine coolant temperature is more than 60

°C, the intake valve timing is controlled by deactivating the

intake valve timing intermediate lock control solenoid valve and releasing the intermediate phase lock.

When the engine is started after warming up, ECM releases the intermediate phase lock immediately after the

engine start and controls the intake valve timing.

EXHAUST VALVE TIMING CONTROL

JPBIA5970GB