Nissan Rogue. Manual - part 443

EC-40

< SYSTEM DESCRIPTION >

[QR25DE]

SYSTEM

by input signals (for engine speed and intake air) from the crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the mass air flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

<Fuel increase>

• During warm-up

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

<Fuel decrease>

• During deceleration

• During high engine speed operation

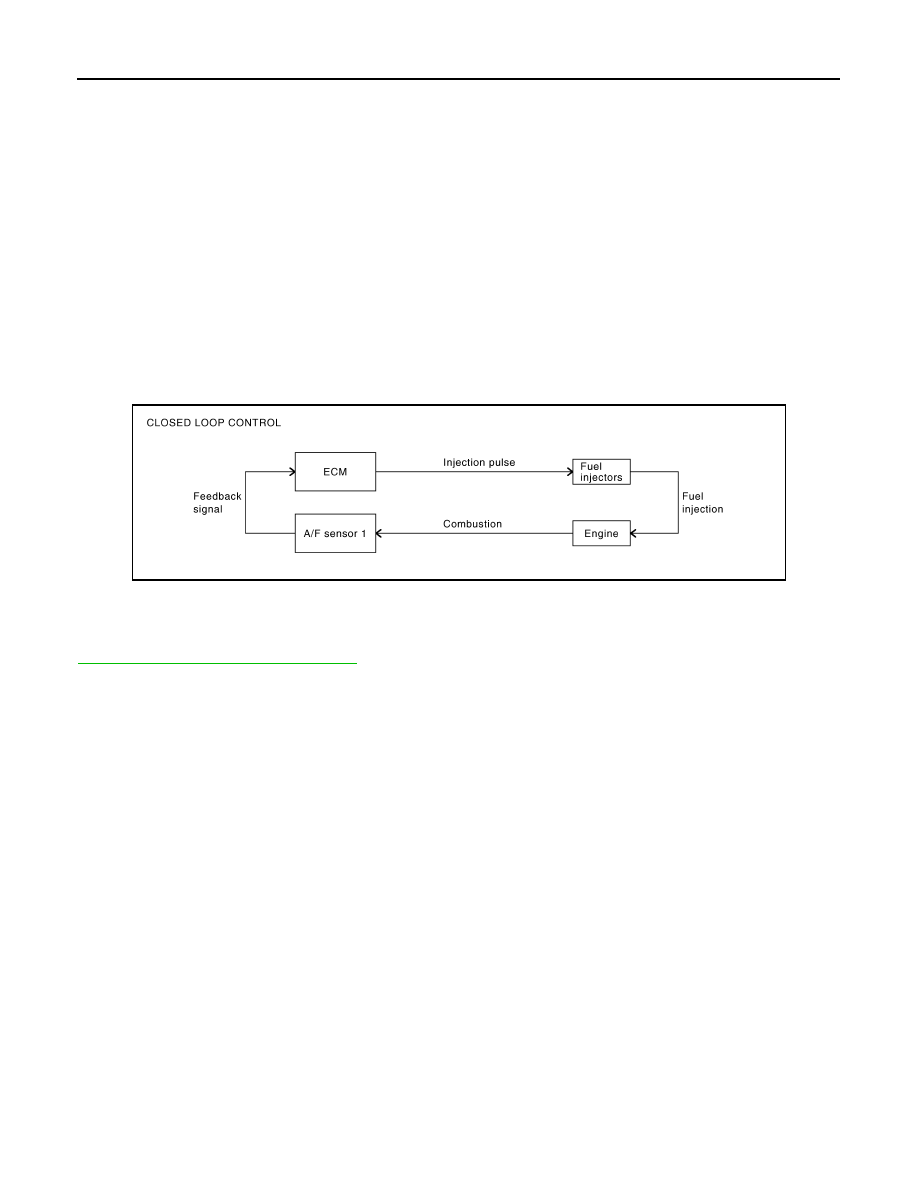

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses A/F

sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The ECM adjusts the

injection pulse width according to the sensor voltage signal. For more information about A/F sensor 1, refer to

EC-24, "Air Fuel Ratio (A/F) Sensor 1"

. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of A/F sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal from heated

oxygen sensor 2.

• Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

- Deceleration and acceleration

- High-load, high-speed operation

- Malfunction of A/F sensor 1 or its circuit

- Insufficient activation of A/F sensor 1 at low engine coolant temperature

- High engine coolant temperature

- During warm-up

- After shifting from N to D

- When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

PBIB2793E