Nissan Rogue. Manual - part 421

DLN-128

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DIFFERENTIAL ASSEMBLY

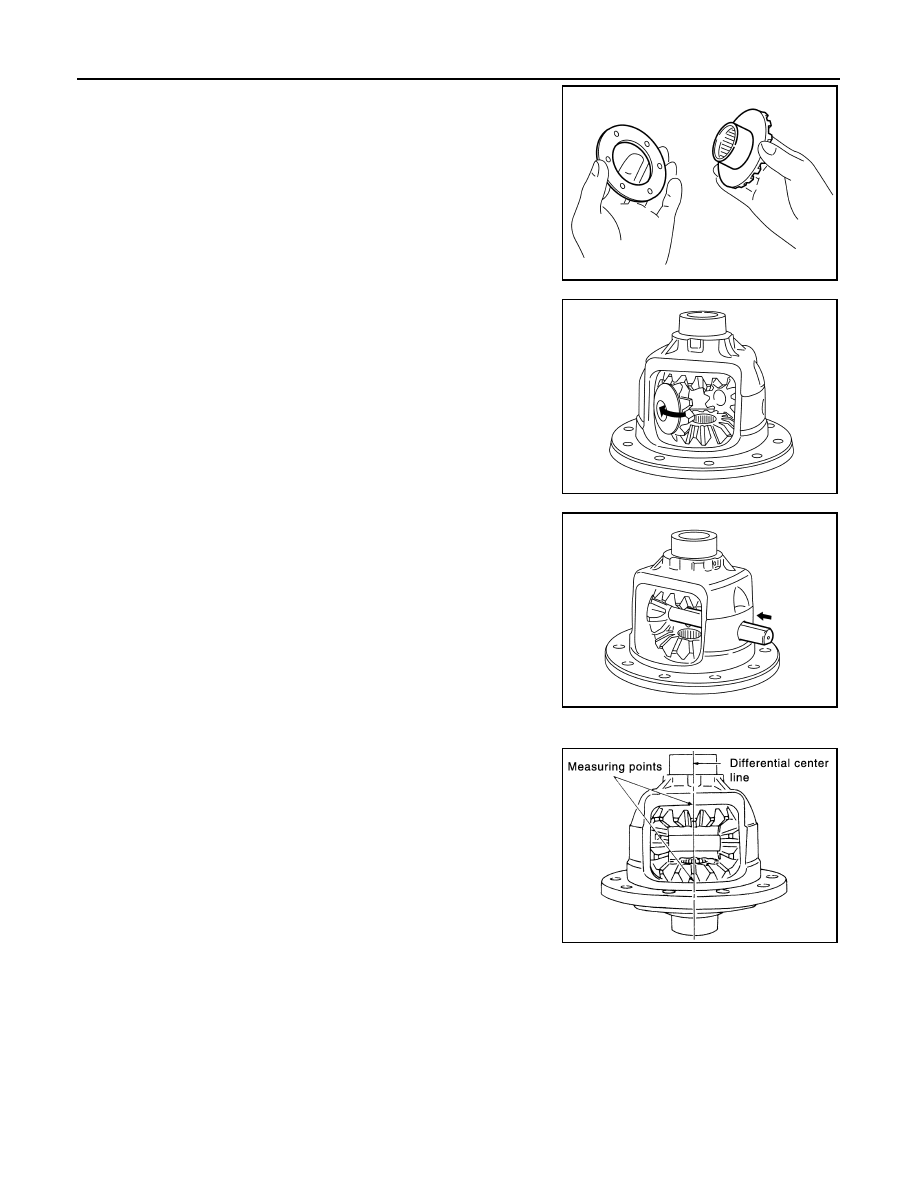

1. Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly or reinstall the old ones on

the side gears.

2. Install side gears and side gear thrust washers into differential

case.

3. Align 2 pinion mate gears in diagonally opposite positions, then

rotate and install them into differential case after installing thrust

washer to pinion mate gear.

4. Align the lock pin holes on differential case with pinion mate

shaft, and install pinion mate shaft.

5. Measure side gear end play. If necessary, select the appropriate side gear thrust washers.

a. Place differential assembly straight up so that side gear to be

measured comes upward.

SDIA0193J

SDIA0194J

SDIA0195J

JPDID0205GB