Nissan Rogue. Manual - part 422

DLN-132

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DIFFERENTIAL ASSEMBLY

a. Set dummy cover shims [SST: KV38108630 (

—

)] to the right and left side bearing adjusting

shims.

b. Temporarily tighten dummy cover [SST: KV38108610 (

—

)] to gear carrier.

c.

Position dummy cover spacers [SST: KV38108621 (

—

)] to dummy cover [SST: KV38108610

(

—

)].

d. Tighten rear cover mounting bolts to the specified torque. Refer to

.

e. Tighten dummy cover spacer mounting bolts evenly to the specified torque.

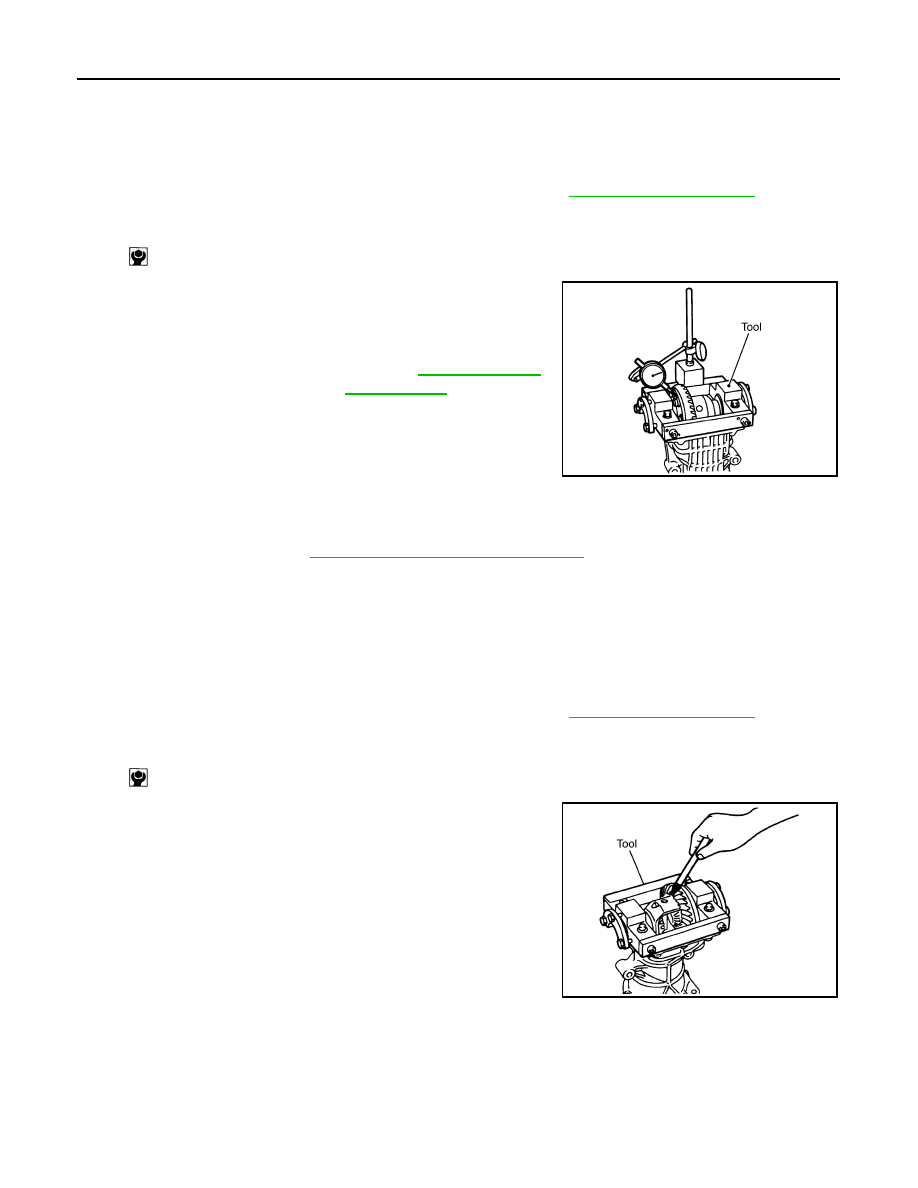

3. Fit a dial indicator to the drive gear back face.

4. Rotate the drive gear to measure runout.

• If the runout is outside of the repair limit, check drive gear

assembly condition; foreign material may be caught between

drive gear and differential case, or differential case or drive

gear may be deformed, etc.

CAUTION:

Replace drive gear and drive pinion as a set.

TOOTH CONTACT

1. Remove rear cover. Refer to

DLN-126, "Disassembly and Assembly"

.

2. Following the procedure below, install a dummy cover set [SST: KV381086S1 (

—

)] to gear car-

rier.

a. Set dummy cover shims [SST: KV38108630 (

—

)] to the right and left side bearing adjusting

shims.

b. Temporarily tighten dummy cover [SST: KV38108610 (

—

)] to gear carrier.

c.

Position dummy cover spacers [SST: KV38108621 (

—

)] to dummy cover [SST: KV38108610

(

—

)].

d. Tighten rear cover mounting bolts to the specified torque. Refer to

.

e. Tighten dummy cover spacer mounting bolts evenly to the specified torque.

3. Apply red lead to drive gear.

CAUTION:

Apply red lead to both the faces of 3 to 4 gears at 4 loca-

tions evenly spaced on drive gear.

: 5.9 N·m (0.6 kg-m, 52 in-lb)

Limit

Drive gear back face

runout

: Refer to

.

PDIA0050E

: 5.9 N·m (0.6 kg-m, 52 in-lb)

PDIA0051E