Nissan Rogue. Manual - part 419

DLN-120

< UNIT REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R145]

REAR FINAL DRIVE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

REAR FINAL DRIVE ASSEMBLY

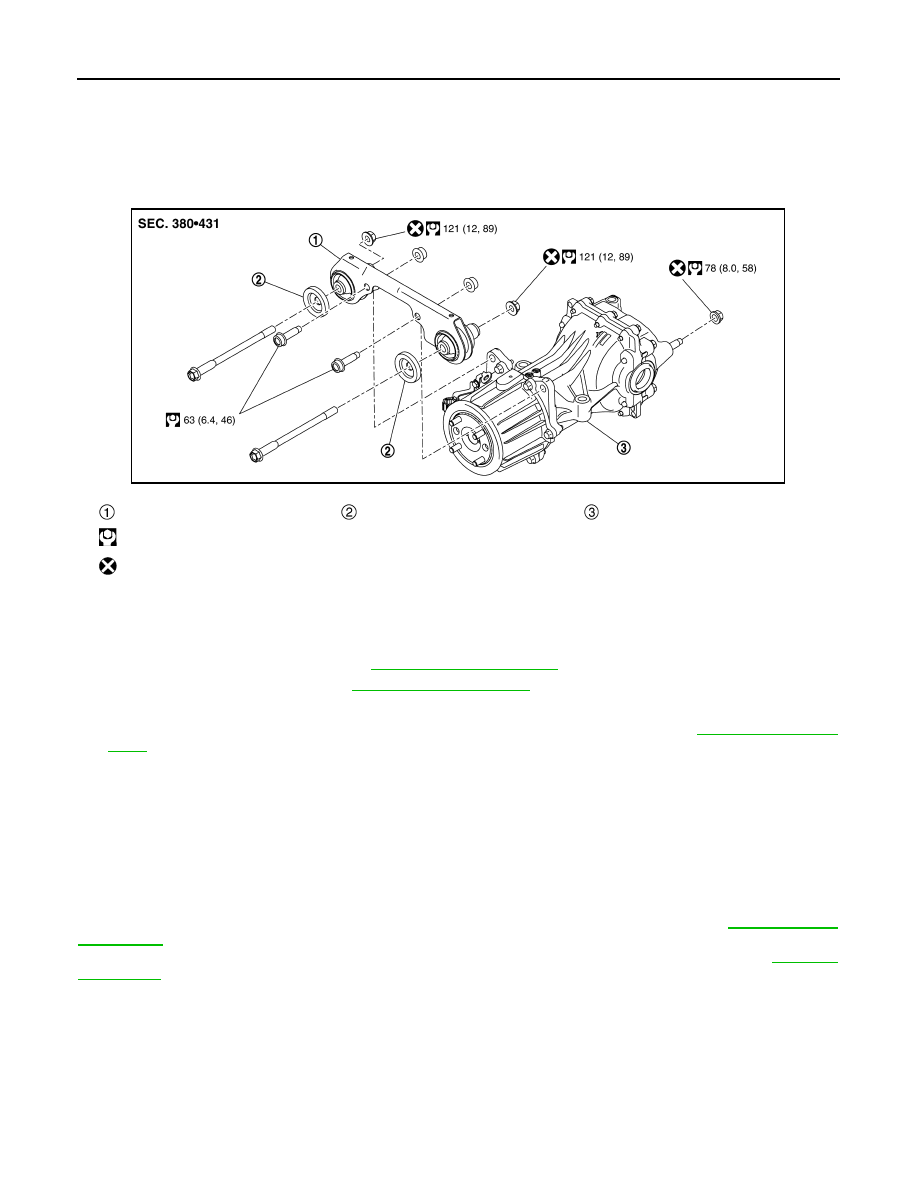

Exploded View

INFOID:0000000011278416

Removal and Installation

INFOID:0000000011278417

REMOVAL

1. Remove rear propeller shaft. Refer to

2. Remove rear drive shafts. Refer to

.

3. Disconnect AWD solenoid harness connector.

4. Remove rear final drive breather hose and electric controlled coupling breather hose.

.

5. Support final drive assembly with a suitable jack.

6. Remove final drive nuts and final drive bolts with power tool.

If necessary, remove final drive bracket and washer with power tool.

CAUTION:

Secure final drive assembly to a suitable jack while removing it.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When replacing rear final drive assembly, perform writing unit characteristics. Refer to

.

When oil leaks while removing final drive assembly, check oil level after the installation. Refer to

Final drive mounting bracket

Mounting stopper

Rear final drive assembly

: N·m (kg-m, ft-lb)

: Always replace after every disassembly.

JSDIA5398GB