Nissan Rogue. Manual - part 412

DLN-92

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21C]

TRANSFER CASE

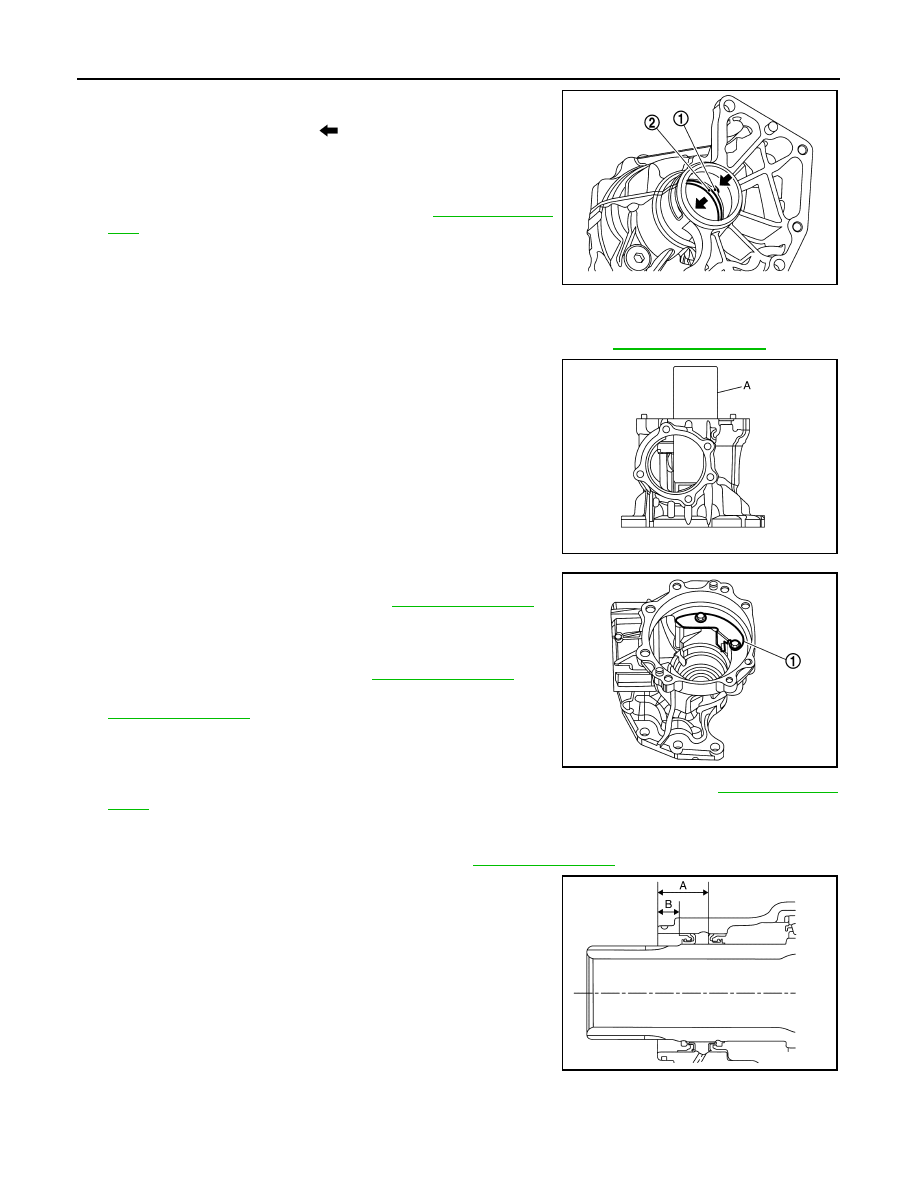

7. Remove the ring gear bearing adjusting shim (transfer case

side) (1) and ring gear bearing outer race (transfer case side) (2)

by tapping from the 2 cutouts (

) on the transfer case.

CAUTION:

Do not damage transfer case.

8. Remove plug and gasket.

9. Perform inspection after disassembly. Refer to

Assembly

INFOID:0000000011278380

1. Select the ring gear bearing adjusting shim (transfer case side). Refer to

2. Install the selected ring gear bearing adjusting shim (transfer

case side) and ring gear bearing outer race (transfer case side)

using suitable tool (A).

CAUTION:

• Do not reuse ring gear bearing.

• Apply gear oil to the ring gear bearing.

3. Install baffle plate (1).

4. Install ring gear shaft assembly. Refer to

CAUTION:

Protect transfer case oil seals beforehand from being dam-

aged by the spline of ring gear shaft.

5. Install drive pinion assembly. Refer to

6. Install transfer cover to check and adjust each part. Refer to

.

NOTE:

At this timing, O-ring installing to transfer cover is not necessary.

Install O-ring after backlash and tooth contact are checked.

7. Check backlash, tooth contact, total preload and companion flange runout. Refer to

CAUTION:

Measure the total preload without oil seals of transfer cover and transfer case.

8. Reinstall transfer cover for installing O-ring. Refer to

.

9. Install oil seals using suitable tool.

CAUTION:

• When checking the total preload torque, measure it with-

out the oil seal, then install the oil seal.

• Do not reuse the oil seal.

• When installing, do not incline oil seal.

• Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference of the oil seal.

• Do not damage oil seals by spline of ring gear shaft.

10. After installing oil seals to transfer case, remove wrapped vinyl from the spline of ring gear shaft.

11. Apply multi-purpose grease lightly and evenly onto an O-ring, and install it to the transfer case.

JSDIA3984ZZ

JSDIA3998ZZ

(A)

: 24.8 mm (0.976 in)

(B)

: 10.3 mm (0.406 in)

JSDIA3982ZZ

JSDIA4047ZZ