Content .. 1160 1161 1162 1163 ..

Nissan Rogue. Manual - part 1162

TM-20

< SYSTEM DESCRIPTION >

[CVT: RE0F10D]

COMPONENT PARTS

• When all of the following conditions are satisfied, the TCM transmits OD OFF indicator lamp signal to the

combination meter via CAN communication. The combination meter turns ON the O/D OFF indicator lamp

on the combination meter, according to the signal.

- TCM receives overdrive control switch via CAN communication from combination meter.

- Selector lever: D position.

LIGHTING CONDITION

When all of the following conditions are satisfied.

• Ignition switch: ON

• Selector lever: D position

• Overdrive control switch is pressed when the O/D OFF indicator lamp is OFF.

SHUTOFF CONDITION

When any of the conditions listed below is satisfied.

• Ignition switch: Other than ON

• Overdrive control switch is pressed when the O/D OFF indicator lamp is ON.

• Selector lever is shifted to other than D position when the O/D OFF indicator lamp is ON.

CVT CONTROL SYSTEM : Shift Position Indicator

INFOID:0000000011279261

TCM transmits shift position signal to combination meter via CAN communication. The actual shift position is

displayed on combination meter according to the signal.

SHIFT LOCK SYSTEM

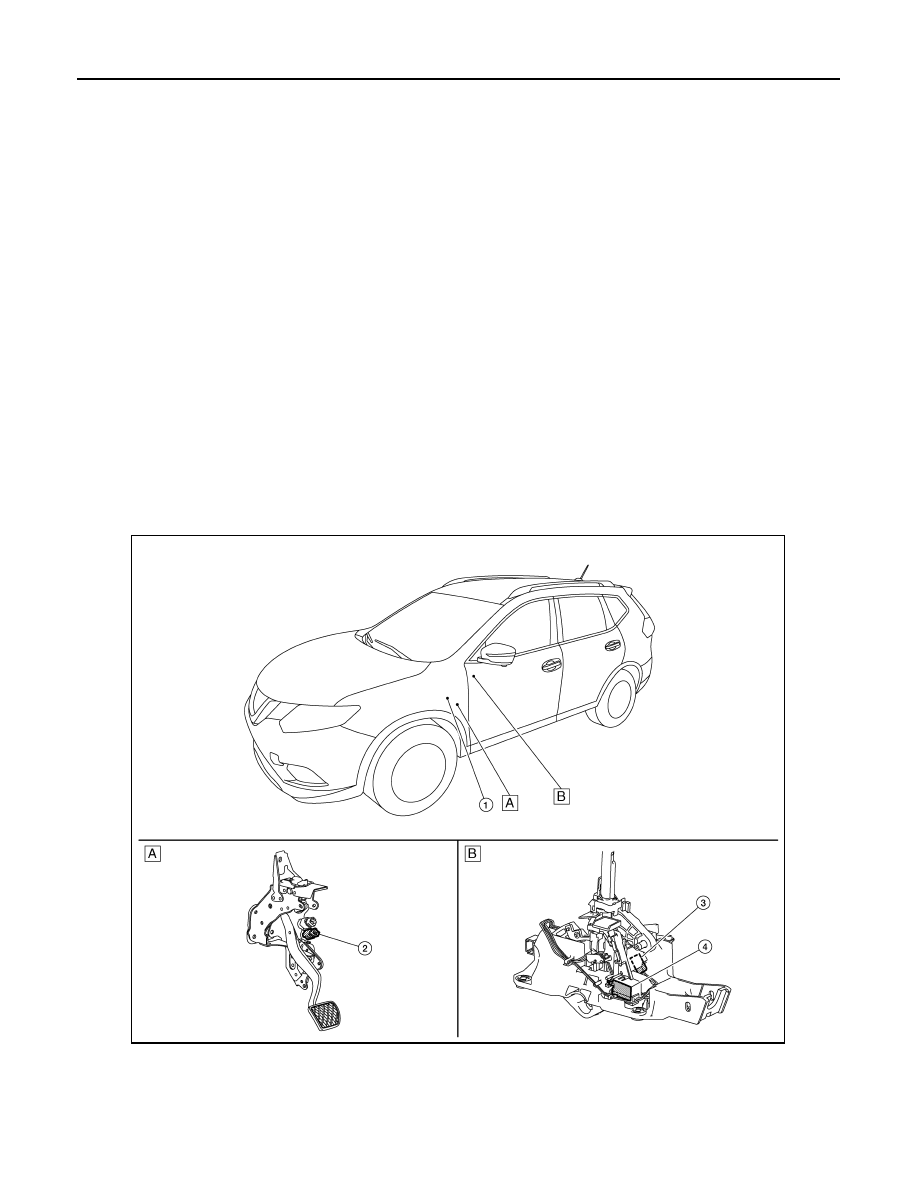

SHIFT LOCK SYSTEM : Component Parts Location

INFOID:0000000011279262

COMPONENT DESCRIPTION

A

Brake pedal, upper

B

CVT shift selector assembly

ALDIA0551ZZ