Nissan Maxima. Manual - part 615

EXL-202

< DTC/CIRCUIT DIAGNOSIS >

[HALOGEN TYPE]

HEADLAMP (HI) CIRCUIT

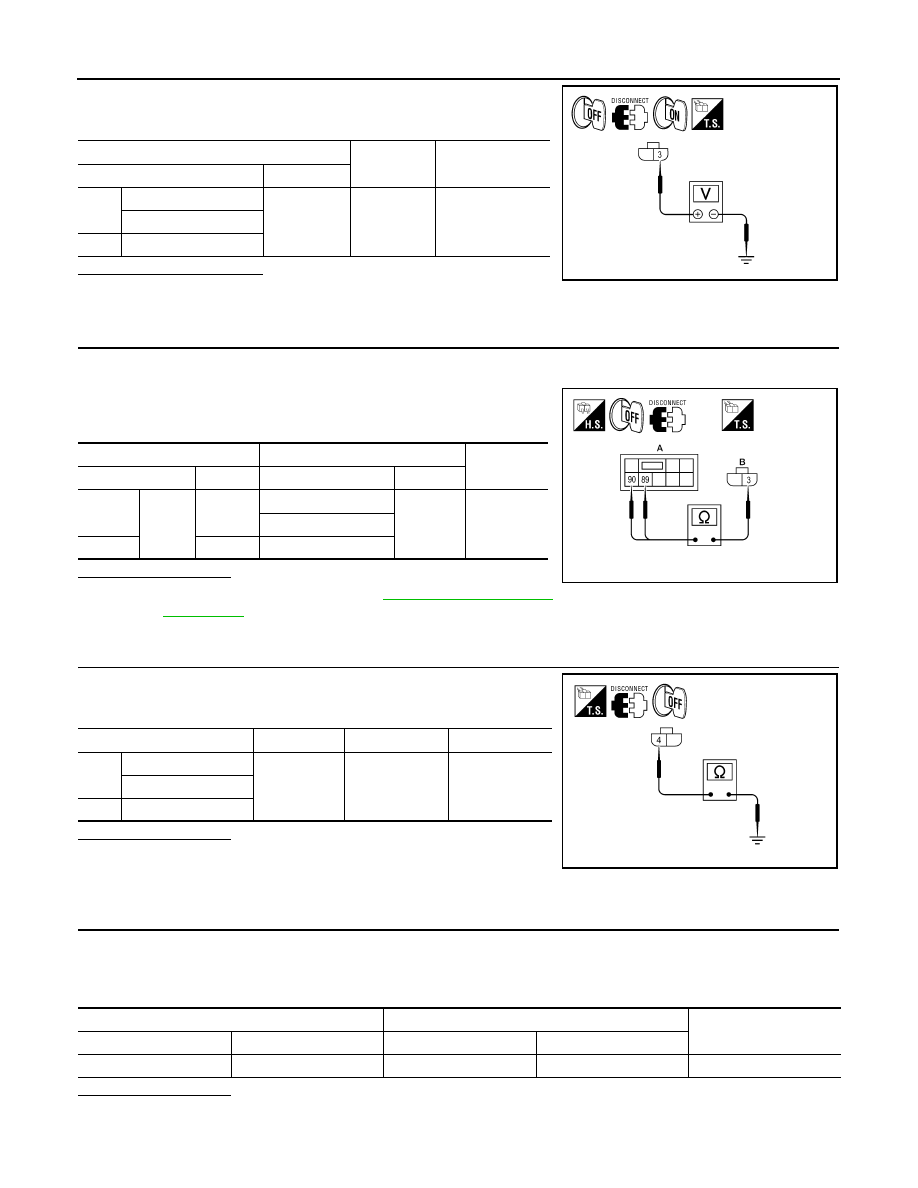

5. With EXTERNAL LAMP ON, check the voltage between the

combination lamp connector and ground.

Is battery voltage present?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E200.

3. Check continuity between the IPDM E/R harness connector (A)

and the front combination lamp harness connector (B).

Does continuity exist?

YES

NO

>> Repair the harnesses or connectors.

4.

CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES

>> Inspect the headlamp bulb.

NO (Except RH with DTRL)>>Repair the harness.

NO (RH with DTRL)>>GO TO 5.

5.

CHECK CONTINUITY BETWEEN FRONT COMBINATION LAMP RH (HI) AND DAYTIME LIGHT RELAY

1. Disconnect daytime light relay connector.

2. Check continuity between front combination lamp RH harness connector and daytime light relay harness

connector.

Does continuity exist?

YES

>> GO TO 6.

NO

>> Repair the harness or connector.

(+)

(

−)

Voltage

Connector

Terminal

RH

E222 (without DTRL)

3

Ground

Battery voltage

E233 (with DTRL)

LH

E213

AWLIA1641ZZ

A

B

Continuity

Connector

Terminal

Connector

Terminal

RH

E200

89

E222 (without DTRL)

3

Yes

E233 (with DTRL)

LH

90

E213

AWLIA1642ZZ

Connector

Terminal

—

Continuity

RH

E222 (without DTRL)

4

Ground

Yes

E233 (with DTRL)

LH

E213

AWLIA1643ZZ

Front combination lamp RH

Daytime light relay

Continuity

Connector

Terminal

Connector

Terminal

E233

4

E228

3

Yes