Nissan Maxima. Manual - part 614

EXL-198

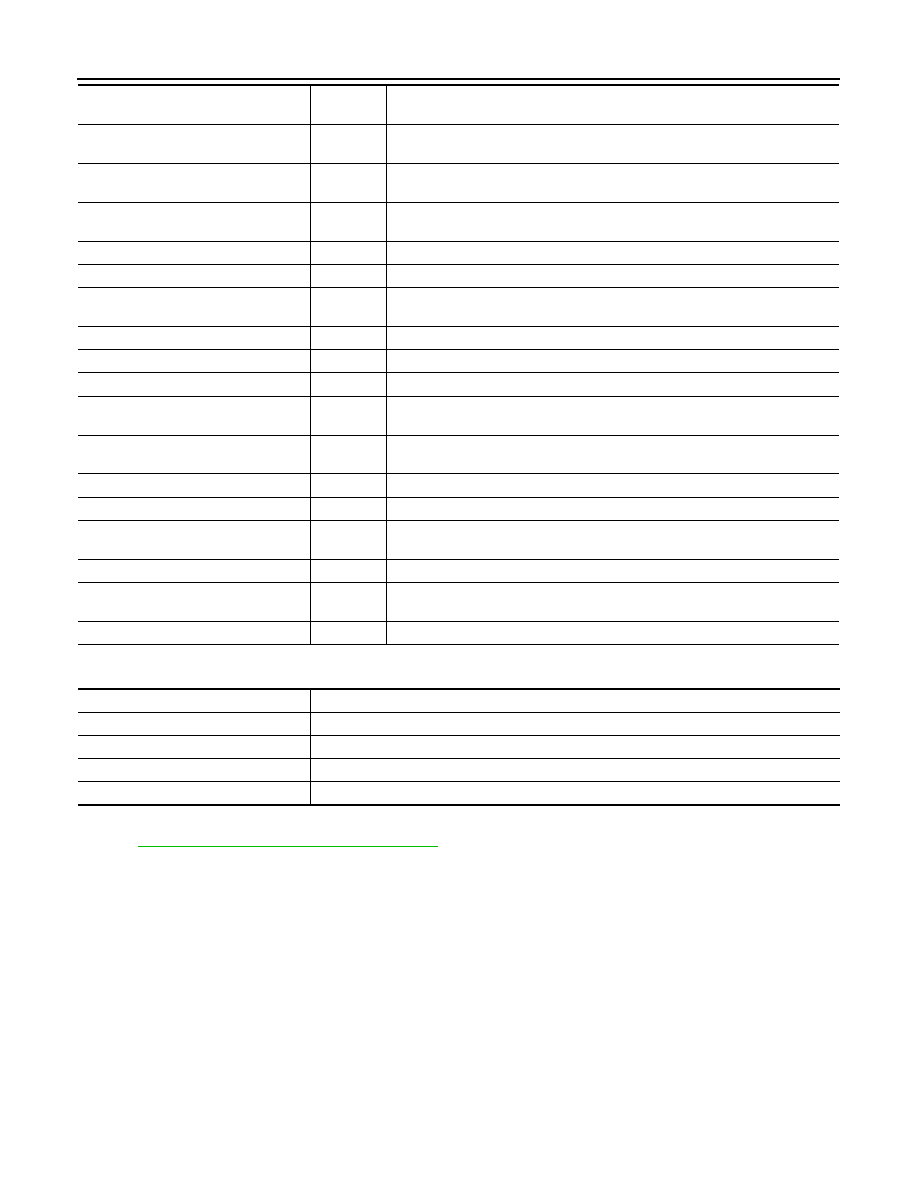

< SYSTEM DESCRIPTION >

[HALOGEN TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

CAN DIAG SUPPORT MNTR

LAN-12, "CAN Diagnostic Support Monitor"

.

HL HI REQ [On/Off]

×

Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off]

×

Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi]

×

Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P]

×

Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK]

×

Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off]

Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off]

×

Indicates condition of ignition relay-1

PUSH SW [On/Off]

Indicates condition of push-button ignition switch

INTER/NP SW [On/Off]

Indicates condition of CVT shift position

ST RLY CONT [On/Off]

Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off]

Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI]

Indicates condition of starter relay and starter control relay

DETENT SW [On/Off]

Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off]

Indicates daytime light request signal received from BCM on CAN communica-

tion line

OIL P SW [Open/Close]

Indicates condition of oil pressure switch

THFT HRN REQ [On/Off]

Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off]

Indicates horn reminder signal received from BCM on CAN communication line

Monitor Item [Unit]

Main

Signals

Description

Test item

Description

HORN

This test is able to check horn operation [On].

FRONT WIPER

This test is able to check wiper motor operation [Hi/Lo/Off].

MOTOR FAN

This test is able to check cooling fan operation [4/3/2/1].

EXTERNAL LAMPS

This test is able to check external lamp operation [Fog/Hi/Lo/Tail/Off].