Nissan Maxima. Manual - part 559

EM-124

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

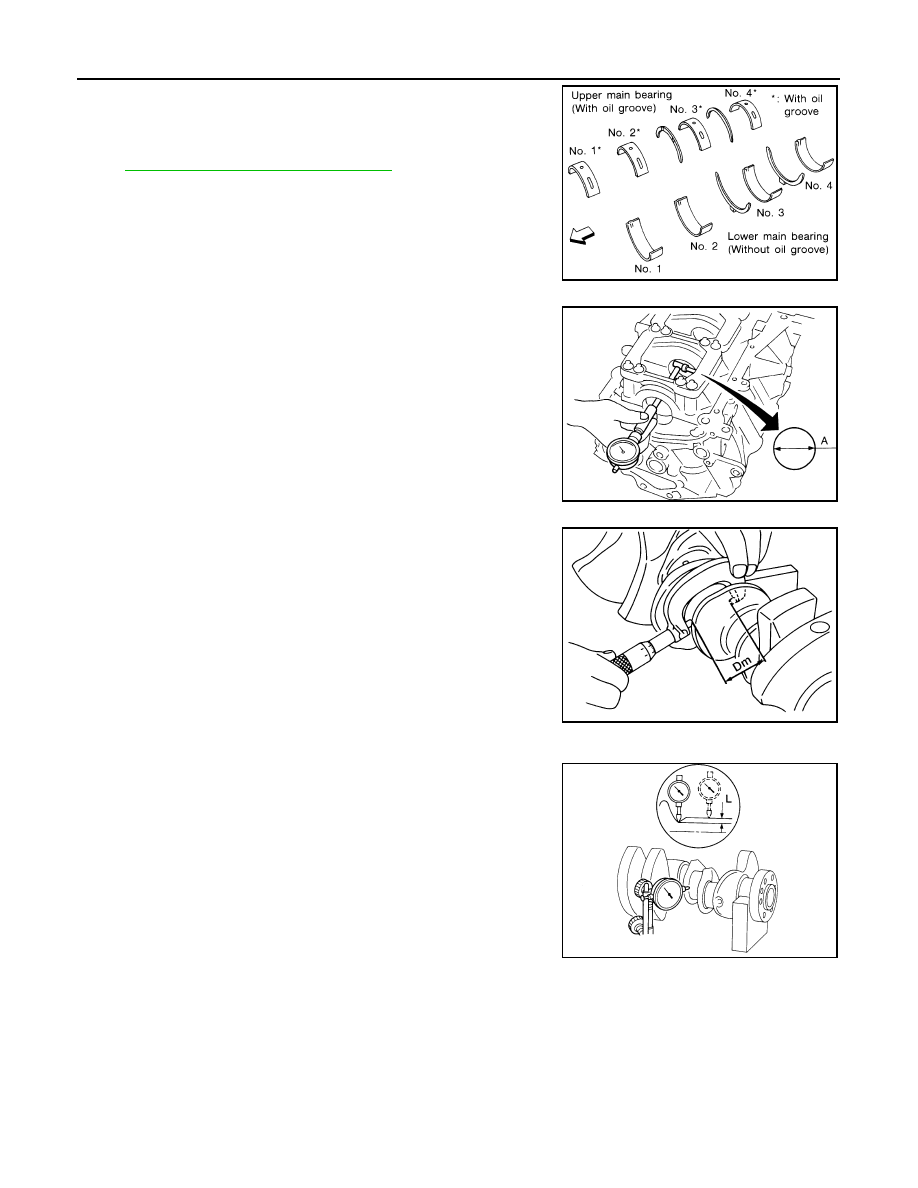

1. Set the main bearings in their proper positions on the cylinder

block and the main bearing cap.

2. Install the main bearing caps and bearing beam to the cylinder

block. Tighten all bolts in the numerical order as specified. Refer

EM-107, "Disassembly and Assembly"

.

3. Measure the inner diameters "A" of each main bearing as

shown.

4. Measure the outer diameters "Dm" of each crankshaft main jour-

nal as shown.

5. Calculate the main bearing clearance.

Main bearing clearance = "A" - "Dm"

• If it exceeds the limit, replace the bearing.

• If clearance cannot be adjusted using any standard bearing

grade, grind crankshaft journal and use an undersized bear-

ing.

• When grinding the crankshaft journal, confirm that the "L"

dimension in the fillet role is more than the specified limit.

6. If the crankshaft or the cylinder block is replaced with a new one, select thickness of the main bearings as

follows:

SEM175F

SEM845E

Standard

: 0.012 - 0.022 mm (0.0005 - 0.0009 in)

Limit

: 0.065 mm (0.0026 in)

AEM033

"L"

: 0.10 mm (0.0039 in)

SEM964