Nissan Maxima. Manual - part 557

EM-116

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

15. Check the connecting rod cap bolts before reusing, then install

in their original position in the connecting rod. The bolts should

screw in smoothly by hand.

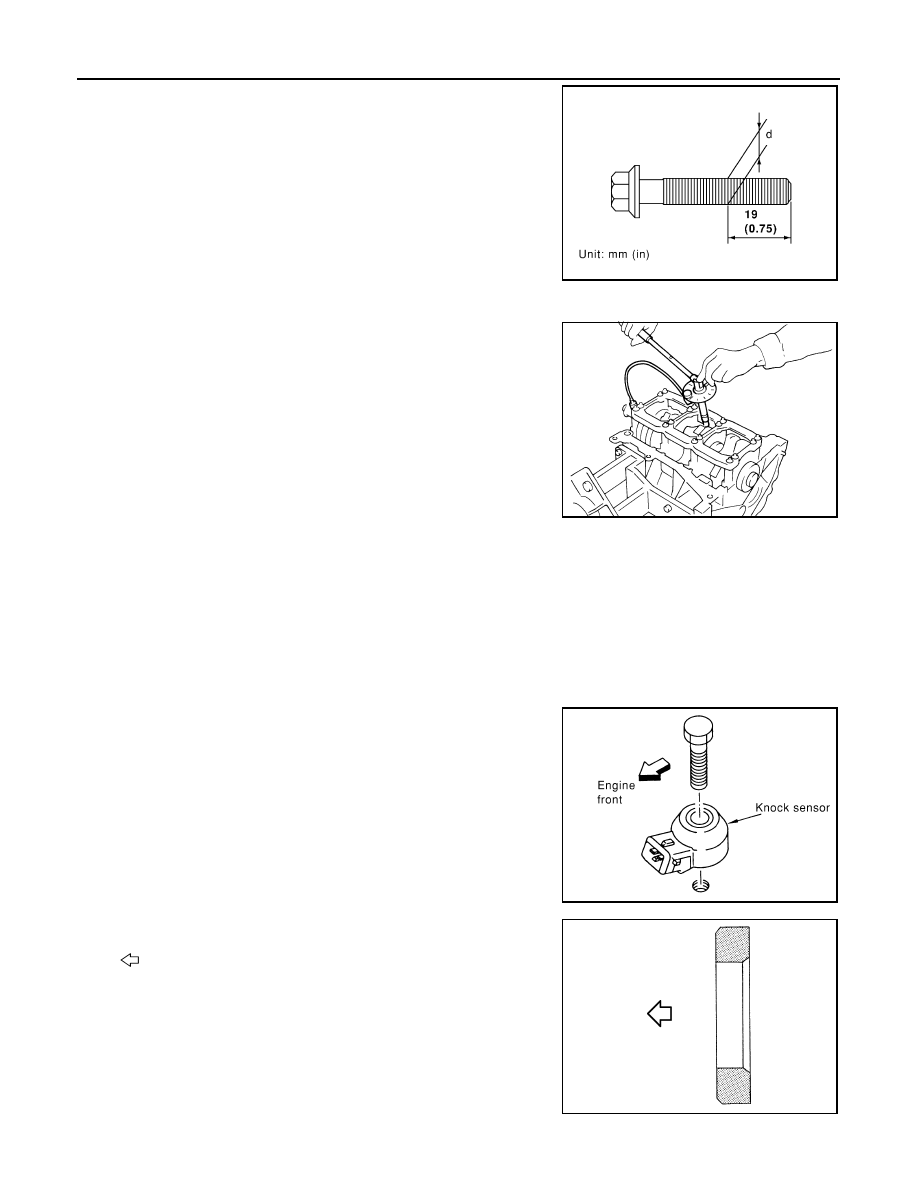

• Measure the outer diameter of the connecting rod cap bolt as

shown.

16. Tighten the connecting rod nuts in two stages using Tool:

CAUTION:

Always use either an angle wrench or protractor. Avoid

tightening based on visual check alone.

• Apply engine oil to the threads and seats of the connecting rod

bolts and nuts.

• After tightening the nuts, make sure that the crankshaft rotates

smoothly.

• Check the connecting rod side clearance. If beyond the limit, replace the connecting rod and/or crank-

shaft.

17. Install the baffle plate to the main bearing beam.

18. Install the knock sensor.

• Make sure that there is no foreign material on the cylinder

block mating surface and the back surface of the knock sen-

sor.

• Install the knock sensor with the connector facing the rear of

the engine.

• Do not tighten the bolts while holding the connector.

• Make sure that the knock sensor does not interfere with other

parts.

CAUTION:

If any impact by dropping occurs to the knock sensor,

replace it with new one.

19. Install the pilot converter with it’s chamfer facing crankshaft as

shown.

•

: Crankshaft side

Outer diameter "d" of the connecting rod bolt

Standard

: 7.90 - 8.00 mm (0.3110 - 0.3150 in)

Limit

: 7.75 mm (0.3051 in)

SEM538G

Stage 1

: 19 - 21 N·m (1.9 - 2.1 kg-m, 14 - 15 ft-lb)

Stage 2

: 90

° - 95° degrees clockwise

Tool number

: KV10112100 (BT-8653-A)

Connecting rod side clearance:

Standard

: 0.20 - 0.35 mm (0.0079 - 0.0138 in)

Limit

: 0.40 mm (0.0157 in)

SEM953E

PBIC0810E

JPBIA0210ZZ