Nissan Maxima. Manual - part 555

EM-108

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

CAUTION:

• Apply new engine oil to parts as marked in illustrations before installation.

• Place removed parts such as bearings and bearing caps in their proper order and direction.

• When installing the connecting rod nuts, and main bearing cap bolts, apply new engine oil to the

threads and mating surfaces

• Do not allow any magnetic materials to contact the signal plate teeth on the drive plate.

DISASSEMBLY

1. Remove the engine assembly. Refer to

EM-103, "Removal and Installation"

.

2. Remove the crankshaft pulley.

• Use a suitable tool to prevent the crankshaft from turning.

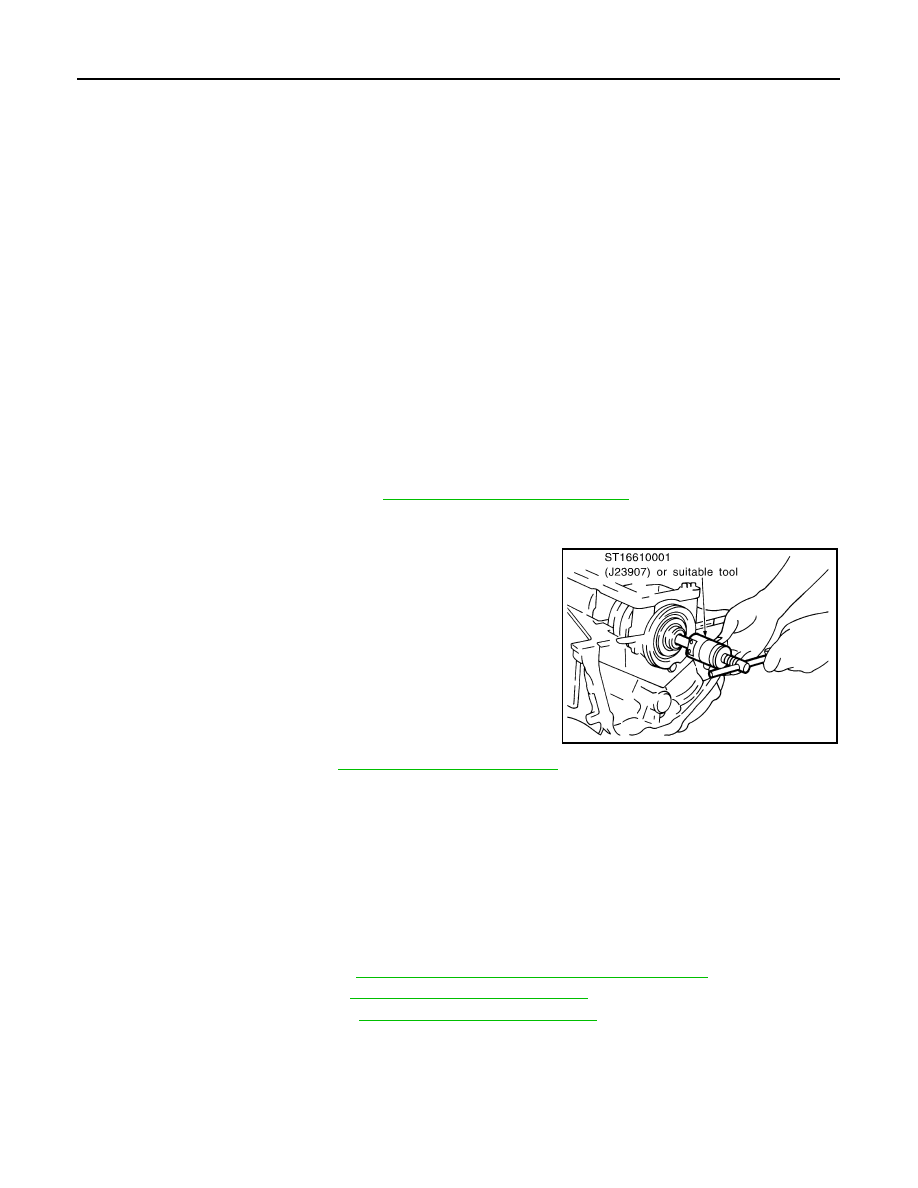

3. Remove pilot converter using Tool.

4. Remove the drive plate. Refer to

.

5. Install the engine on engine stand.

CAUTION:

Use an engine stand that has a load capacity [approximately 240kg (529) or more] large enough for

supporting the engine weight.

Before removing the hanging chains, make sure the engine stand is stable and there is no risk of

overturning.

6. Remove the knock sensor.

CAUTION:

Carefully handle sensor to avoid shocking it.

7. Drain the engine of all coolant and oil.

8. Remove the upper oil pan. Refer to

EM-37, "Removal and Installation (Upper Oil Pan)"

9. Remove the timing chain. Refer to

EM-64, "Removal and Installation"

10. Remove the cylinder head. Refer to

EM-90, "Removal and Installation"

.

1.

Reinforcement plate

2.

Drive plate

3.

Rear oil seal retainer

4.

Rear oil seal

5.

Sub harness

6.

Knock sensor

7.

Cylinder block

8.

Thrust bearing (upper)

9.

Main bearing (upper)

10. Crankshaft

11. Crankshaft key

12. Thrust bearing (lower)

13. Main bearing (lower)

14. Main bearing cap

15. Main bearing cap bolt

16. Main bearing beam

17. Baffle plate

18. Connecting rod bolt

19. Connecting rod bearing cap

20. Connecting rod bearing

21. Connecting rod

22. Snap ring

23. Piston pin

24. Piston

25. Oil ring

26. Second ring

27. Top ring

28. Pilot converter

29. Oil jet

30. Gasket (for Canada)

31. Cylinder block heater (for Canada)

A.

Crankshaft side

B.

Chamfered

C.

Refer to INSTALLATION

D.

Front mark

Tool number

: ST16610001 (J-23907)

SEM005G