Nissan Maxima. Manual - part 551

EM-92

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

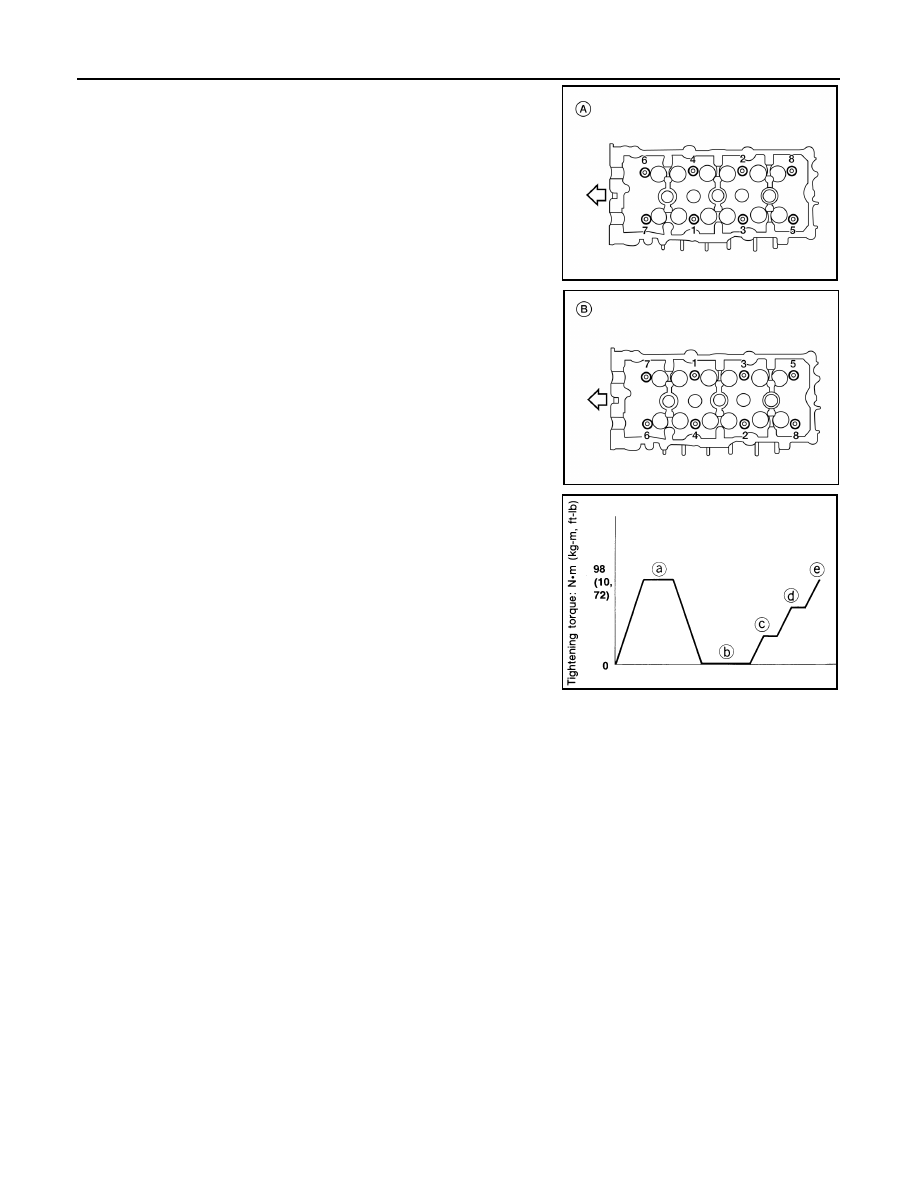

4. Install the cylinder heads RH (A) and LH (B) on the cylinder

block. Tighten the cylinder head bolts in the five steps in the

numerical order as shown using Tool.

• Tightening procedure:

5. Installation of the remaining components is in the reverse order of removal.

Tool Number

: KV10112100 (BT-8653-A)

AWBIA1412ZZ

AWBIA1413ZZ

Cylinder head bolts

Step a

: 98.1 N·m (10 kg-m, 72 ft-lb)

Step b

: Loosen in the reverse order of tightening

Step c : 39.2 N·m (4.0 kg-m, 29 ft-lb)

Step d

: 103

° degrees rotation clockwise

Step e

: 103

° degrees rotation clockwise

SEM879EA