Nissan Maxima. Manual - part 550

EM-88

< REMOVAL AND INSTALLATION >

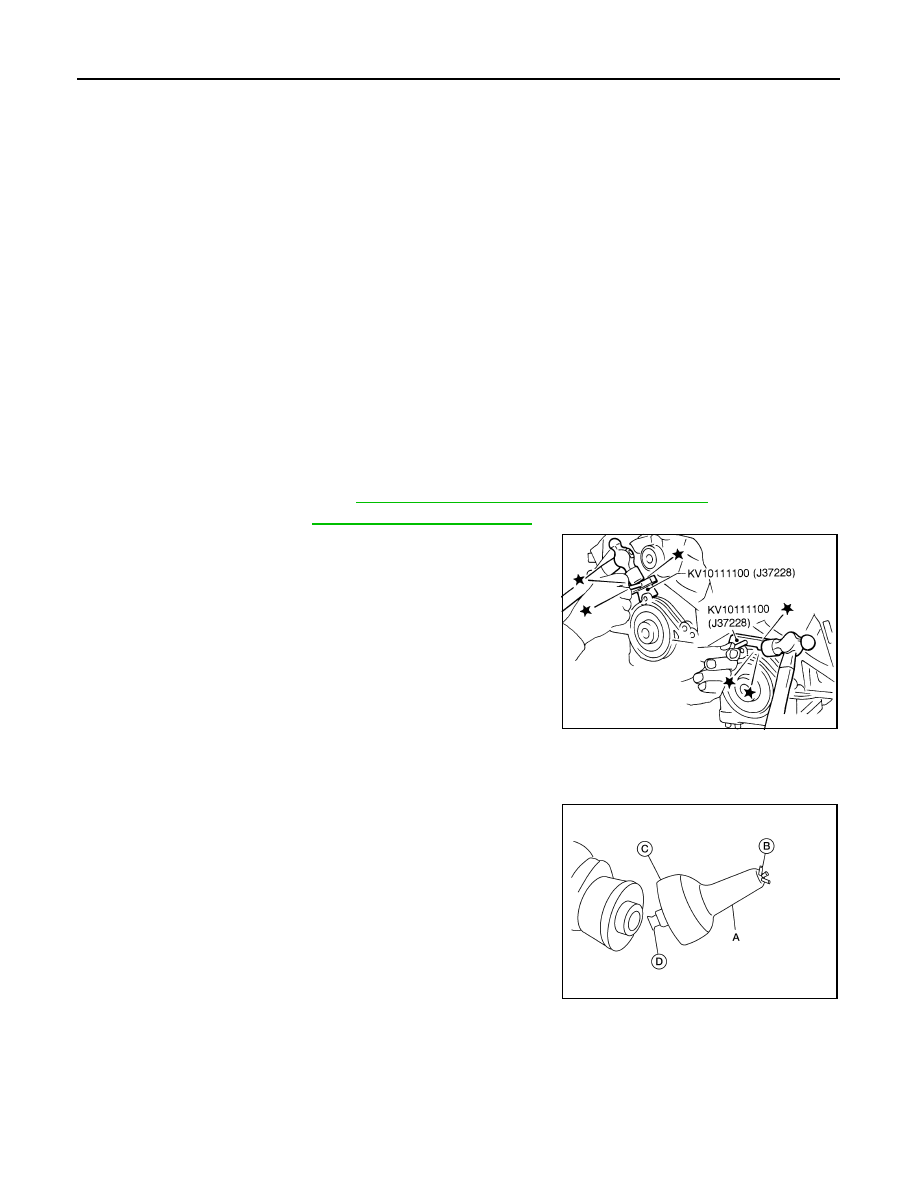

OIL SEAL

2. Install crankshaft pulley and tighten the bolt in two steps.

• Lubricate thread and seat surface of the bolt with new engine oil.

• For the second step angle tighten using Tool.

3. Remove the Tool to unlock the drive plate.

CAUTION:

Do not damage the ring gear teeth, or the signal plate teeth behind the ring gear, when removing

the Tool.

4. Installation of the remaining components is in reverse order of removal.

Removal and Installation of Rear Oil Seal

INFOID:0000000009466045

REMOVAL

1. Remove the upper oil pan. Refer to

EM-37, "Removal and Installation (Upper Oil Pan)"

2. Remove drive plate. Refer to

3. Remove rear oil seal retainer using Tool.

CAUTION:

• Be careful not to damage mating surface.

• If rear oil retainer is removed, replace it with a new one

NOTE:

Rear oil seal and retainer form a single part and are replaced as

an assembly.

INSTALLATION

1. Remove old liquid gasket material from mating surface of cylinder block and oil pan using a suitable

scraper.

2. Install the rear oil seal retainer using Tool (A).

a. Loosen the wing nut (B) on the end of the Tool (A).

b. Insert the arbor (D) into the crankshaft pilot hole until the outer

lip (C) of the Tool (A) covers the edge of the crankshaft sealing

surface.

c.

Tighten the wing nut (B) to secure the Tool (A) to the crankshaft.

Step 1

: 44.1 N·m (4.5 kg-m, 33 ft-lb)

Step 2

: 84

° - 90° degrees clockwise

Tool number

: KV10112100 (BT-8653-A)

Tool number

: — (J-50288)

Tool Number

: KV10111100 (J-37228)

SEM830E

Tool number

: — (J-47128)

ALBIA0652ZZ