Content .. 1161 1162 1163 1164 ..

Nissan Maxima. Manual - part 1163

TM-116

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F09B]

SHIFT LOCK SYSTEM

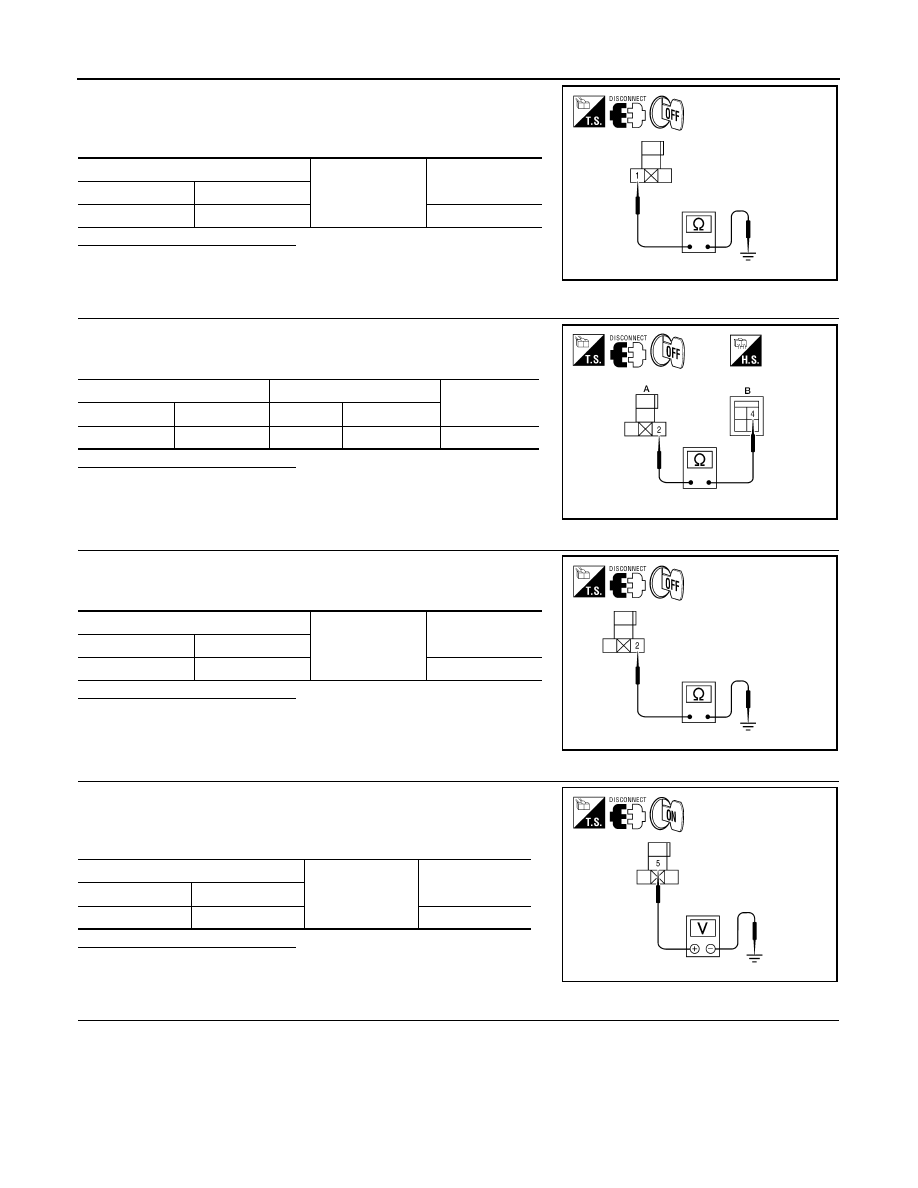

1. Remove shift lock relay.

2. Check continuity between shift lock relay connector E27 termi-

nal 1 and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace damaged parts.

4.

CHECK HARNESS BETWEEN SHIFT LOCK RELAY AND STOP LAMP SWITCH FOR OPEN

Check continuity between shift lock relay connector E27 (A) terminal

2 and stop lamp switch connector E38 (B) terminal 4.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace damaged parts.

5.

CHECK HARNESS BETWEEN SHIFT LOCK RELAY AND STOP LAMP SWITCH FOR SHORT CIRCUIT

Check continuity between shift lock relay connector E27 terminal 2

and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace damaged parts.

6.

CHECK POWER SOURCE (SHIFT LOCK RELAY)

1. Turn ignition switch ON.

2. Check voltage between shift lock relay connector E27 terminal 5

and ground.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 7.

7.

CHECK HARNESS BETWEEN FUSE BLOCK (J/B) AND SHIFT LOCK RELAY FOR OPEN

1. Turn ignition switch OFF.

Shift lock relay

Ground

Continuity

Connector

Terminal (+)

E27

1

Yes

AWDIA0586ZZ

Shift lock relay

stop lamp switch

Continuity

Connector

Terminal

Connector

Terminal

E27 (A)

2

E38 (B)

4

Yes

AWDIA0587ZZ

Shift lock relay

Ground

Continuity

Connector

Terminal

E27

2

No

AWDIA0588ZZ

Shift lock relay

Ground

Voltage (Approx.)

Connector

Terminal

E27

5

Battery voltage

AWDIA0589ZZ