Nissan Altima HL32 Hybrid. Manual - part 611

P0A1D-924, P0A1D-925

HBC-193

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

P0A1D-924, P0A1D-925

Description

INFOID:0000000004211864

The hybrid vehicle control ECU monitors its internal operation and detects malfunctions.

DTC Logic

INFOID:0000000004211865

DTC DETECTION LOGIC

The hybrid vehicle control ECU performs diagnostic monitoring to verify proper operation of internal ECUsys-

tems. In this diagnostic monitor, the hybrid vehicle control ECU checks the communication bus offcount and

the message register of the CAN (Controller Area Network) controller. If the hybrid vehiclecontrol ECU detects

an error in the communication bus off count or message register, it will conclude thatthere is a malfunction in

the hybrid vehicle control ECU. The hybrid vehicle control ECU will illuminate the MIL and set a DTC.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC confirmation procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check DTC.

Is DTC detected?

YES

>> Go to

HBC-193, "Diagnosis Procedure"

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000004211866

1.

PRECONDITIONING

• Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with

converter assembly, take safety precautions such as wearing insulated gloves and removing the service

plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent

other technicians from accidentally reconnecting it while you are working on the high-voltage system.

• After disconnecting the service plug grip, wait for at least 10 minutes before touching any of the high-voltage

connectors or terminals.

• Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with

converter assembly.

>> GO TO 2.

2.

REPLACE HYBRID VEHICLE CONTROL ECU

HBC-644, "Removal and Installation"

>> INSPECTION END

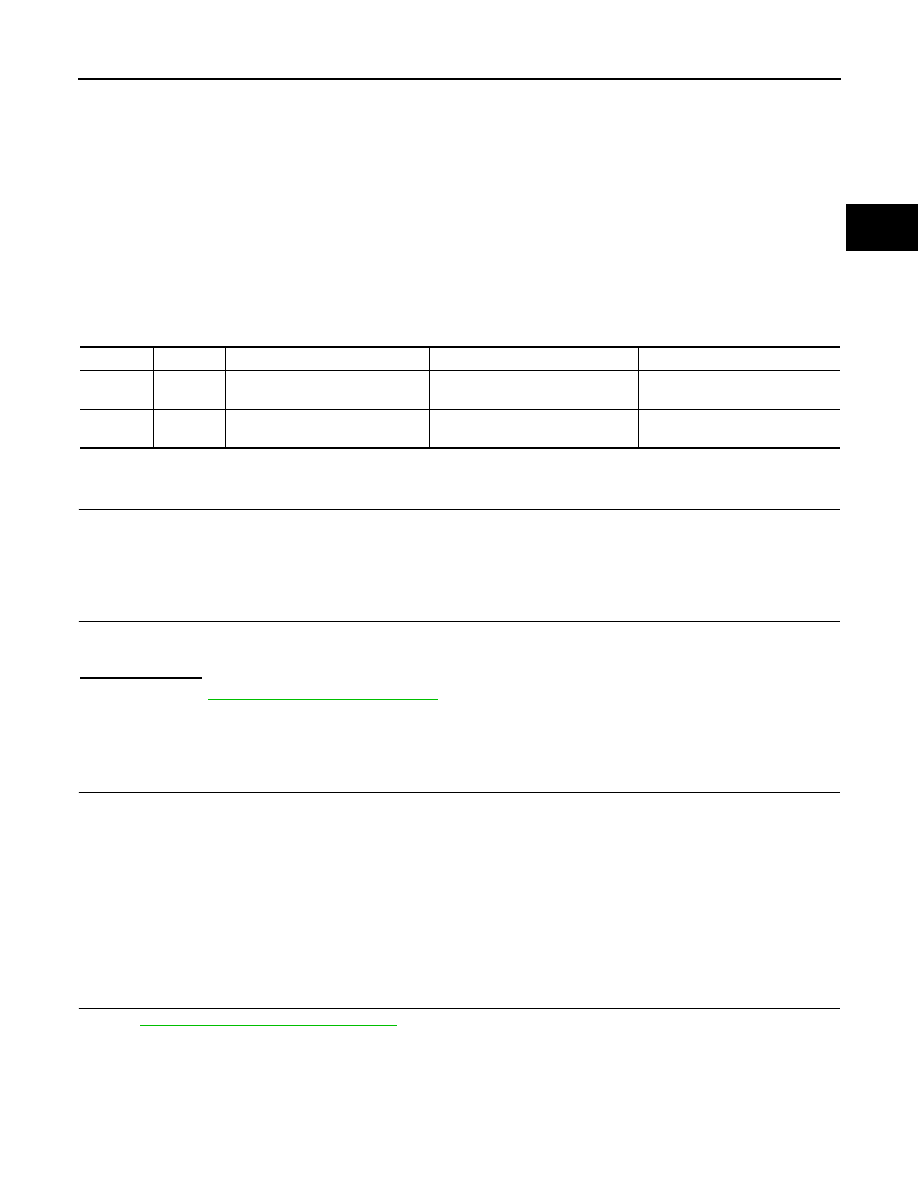

DTC No.

INF code

Trouble diagnosis name

DTC detecting condition

Possible cause

P0A1D

924

Hybrid Powertrain Control Module

ECU internal error is detected.

(Resister value stuck-CAN BUS 1)

Hybrid vehicle control ECU

P0A1D

925

Hybrid Powertrain Control Module

ECU internal error is detected.

(Resister value stuck-CAN BUS 2)

Hybrid vehicle control ECU