Nissan Altima HL32 Hybrid. Manual - part 612

P0A1F-150, P0A1F-157

HBC-197

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

5. Connect the auxiliary battery positive terminal cable of the frame wire.

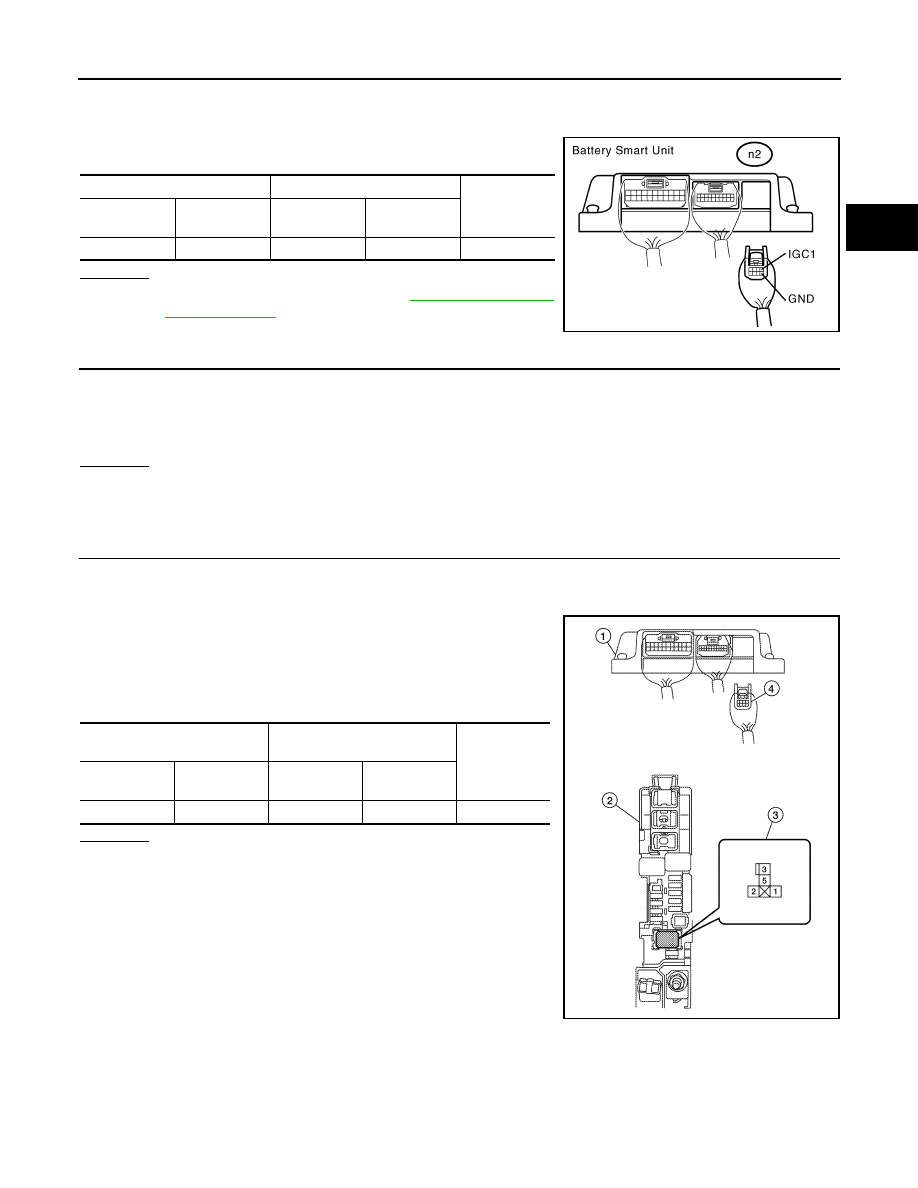

6. Disconnect the n2 battery smart unit connector.

7. Turn ignition switch ON.

8. Measure the voltage according to the value(s) in the table below.

OK or NG

OK

>> Replace battery smart unit (See

).

NG

>> GO TO 4.

4.

CHECK FUSE (NO. 68)

1. Remove the 10A fuse (No. 68) from the high voltage fuse and fusible link box.

2. Measure the resistance of the fuse.

OK or NG

OK

>> GO TO 5.

NG

>> Replace fuse.

5.

CHECK HARNESS AND CONNECTOR (BATTERY SMART UNIT - HIGH VOLTAGE FUSE AND FUSIBLE

LINK BOX)

CAUTION:

Be sure to wear insulated gloves.

1. Install the 10A fuse to the high voltage fuse and fusible link box.

2. Remove the IGCT relay (3) from the high voltage fuse and fus-

ible link box (2).

3. Disconnect connector n2 (4) from the battery smart unit (1).

4. Measure the resistance according to the value(s) in the table

below.

OK or NG

OK

>> Check and repair power source circuit.

NG

>> Repair or replace harness or connector.

Battery smart unit

Battery smart unit

Voltage

Harness

connector

Terminal

Harness

connector

Terminal

n2

1 (IGC1)

n2

5 (GND)

8.6 V or more

JMCIA0191GB

Resistance

: Below 1

Ω

Battery smart unit

high voltage fuse and fusible

link box

Resistance

Harness

connector

Terminal

Harness

connector

Terminal

n2

1 (IGC1)

V-1

5 (IGCT relay)

Below 1

Ω

ALCIA0107ZZ