Nissan Altima HL32 Hybrid. Manual - part 486

HA-6

< PRECAUTION >

PRECAUTIONS

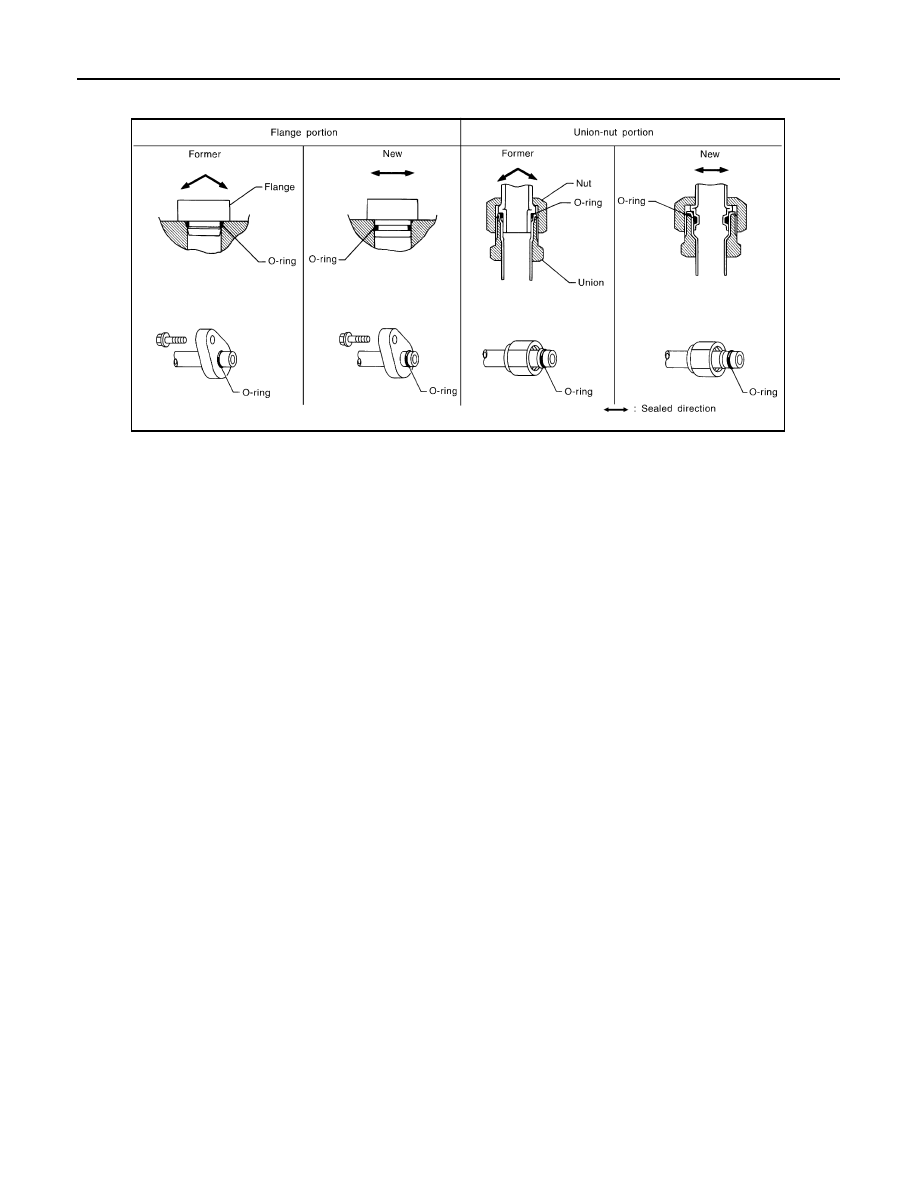

• The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby facili-

tating piping connections.

O-RING AND REFRIGERANT CONNECTION

SHA815E