Nissan Altima HL32 Hybrid. Manual - part 409

EXL-36

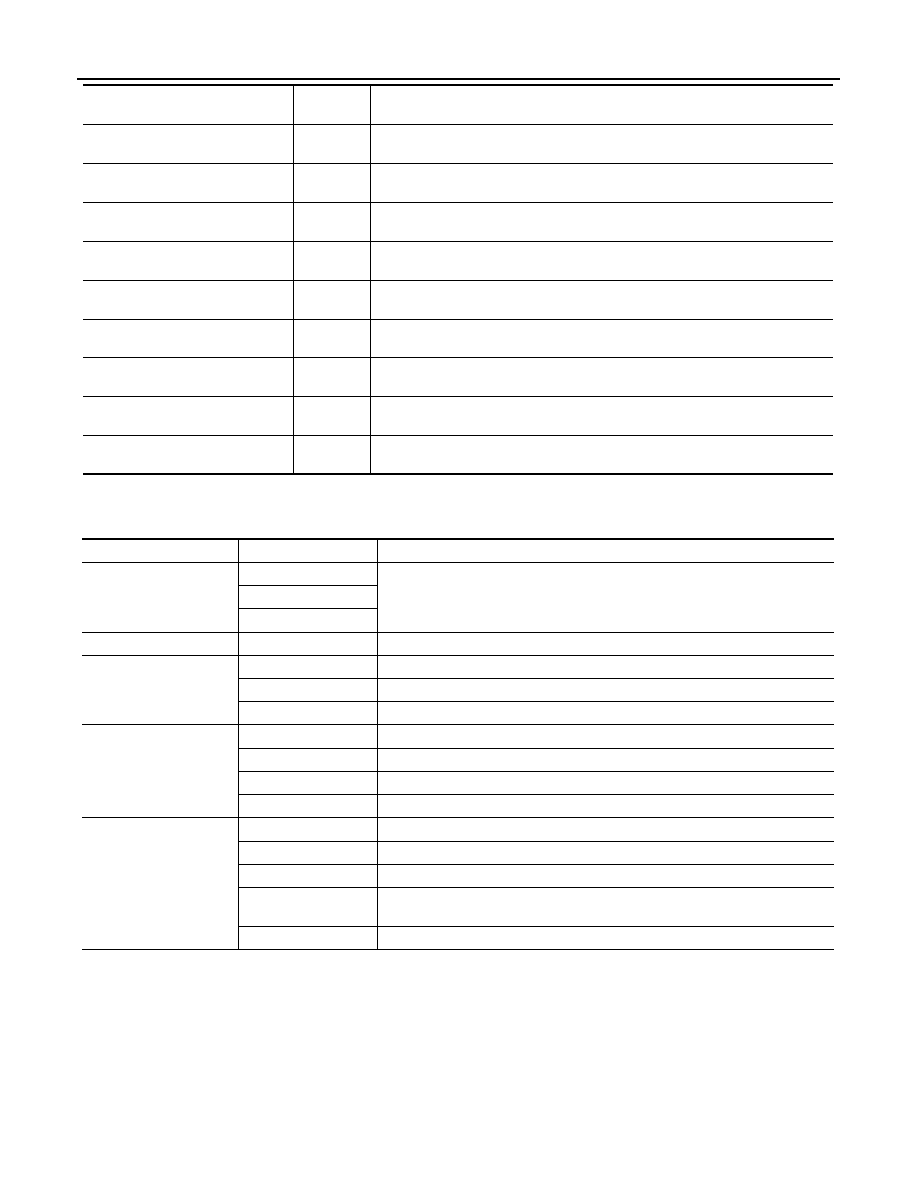

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Test item

PUSH SW

[OFF/ON]

Displays the status of the push-button ignition switch judged by IPDM E/R.

DETENT SW

[OFF/ON]

Displays the status of the CVT device (detention switch) judged by IPDM E/R.

S/L RLY -REQ

[OFF/ON]

Displays the status of the electronic steering column lock relay request received

from BCM via CAN communication.

S/L STATE

[LOCK/UNLK/UNKWN]

Displays the status of the electronic steering column lock judged by IPDM E/R.

DTRL REQ

[OFF]

NOTE:

This item is displayed, but cannot be monitored.

OIL P SW

[OPEN/CLOSE]

Displays the status of the oil pressure switch judged by IPDM E/R.

THFT HRN REQ

[OFF/ON]

Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[OFF/ON]

Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

CRNRNG LMP REQ

[OFF]

NOTE:

This item is displayed, but cannot be monitored.

Monitor Item

[Unit]

MAIN SIG-

NALS

Description

Test item

Operation

Description

CORNERING LAMP

OFF

NOTE:

This item is displayed, but cannot be monitored.

LH

RH

HORN

ON

Operates horn relay for 20 ms.

FRONT WIPER

OFF

OFF

LO

Operates the front wiper relay.

HI

Operates the front wiper relay and front wiper high relay.

MOTOR FAN

1

OFF

2

Outputs 50% pulse duty signal (PWM signal) to the cooling fan control module.

3

Outputs 80% pulse duty signal (PWM signal) to the cooling fan control module.

4

Outputs 100% pulse duty signal (PWM signal) to the cooling fan control module.

EXTERNAL LAMPS

OFF

OFF

TAIL

Operates the tail lamp relay.

LO

Operates the headlamp low relay.

HI

Operates the headlamp low relay and ON/OFF the headlamp high relay at 1 sec-

ond intervals.

FOG

Operates the front fog lamp relay