Nissan Altima HL32 Hybrid. Manual - part 351

EC-388

< COMPONENT DIAGNOSIS >

[QR25DE]

FUEL PUMP

Is the inspection result normal?

YES

>> GO TO 13.

NO

>> GO TO 7.

6.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E29, B10

• IPDM E/R connector E18

• Harness for open or short between IPDM E/R and condenser-1

>> Repair open circuit or short to power in harness or connectors.

7.

CHECK CONDENSER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect dropping resistor harness connector.

3. Check the continuity between condenser-1 harness connector and ground.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair open circuit or short to power in harness or connectors.

8.

CHECK CONDENSER-1

EC-389, "Component Inspection (Condenser-1)"

.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace condenser-1.

9.

CHECK FUEL PUMP POWER SUPPLY CIRCUIT-III

1. Disconnect “fuel level sensor unit and fuel pump” harness connector.

2. Check the continuity between IPDM E/R harness connector and “fuel level sensor unit and fuel pump” and

ground.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> GO TO 10.

10.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E29, B10

• Harness for open or short between “fuel level sensor unit and fuel pump” and IPDM E/R

• Harness for open or short between “fuel level sensor unit and fuel pump” and ground

>> Repair open circuit or short to power in harness or connectors.

11.

CHECK FUEL PUMP GROUND CIRCUIT

1. Check the continuity between “fuel level sensor unit and fuel pump” and ground.

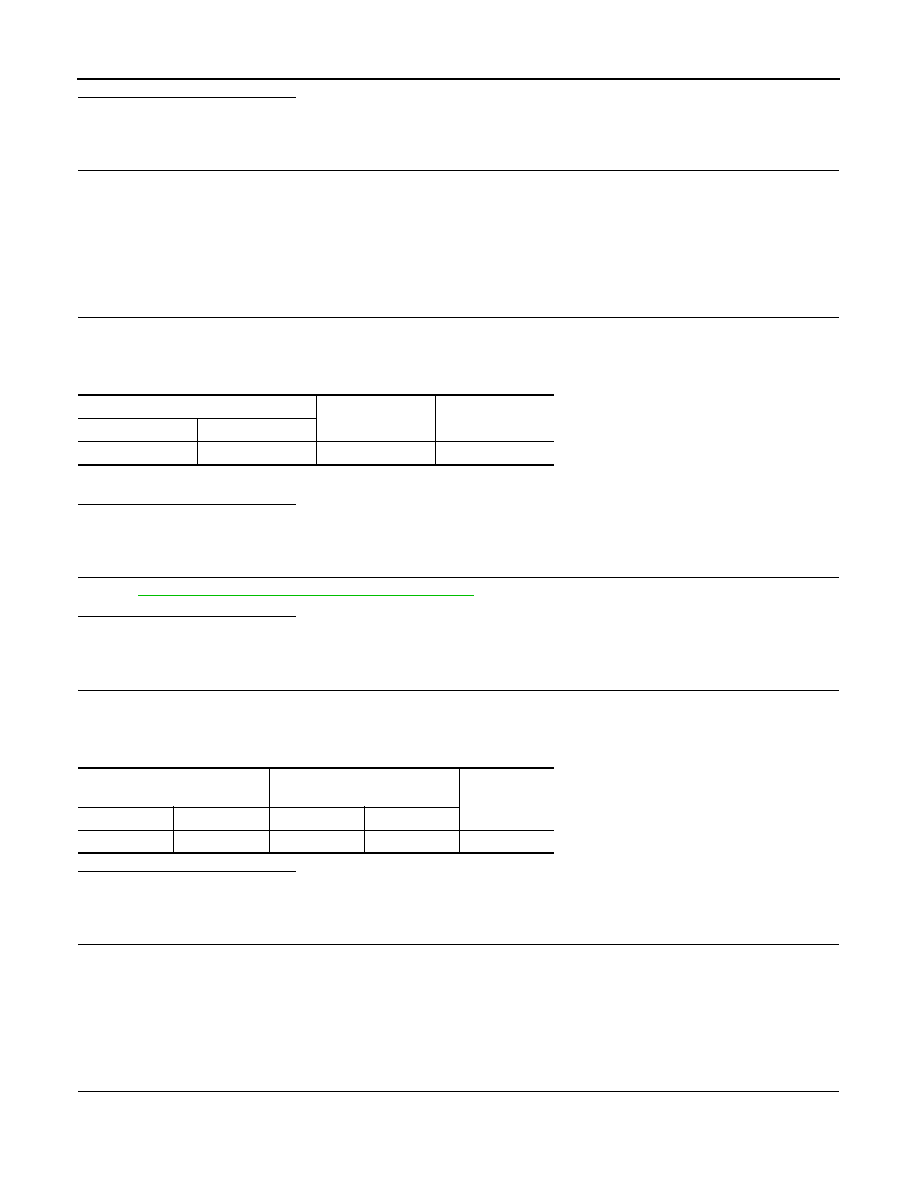

Condenser-1

Ground

Continuity

Connector

Terminal

B17

2

Ground

Existed

IPDM E/R

Fuel level sensor unit and fuel

pump

Continuity

Connector

Terminal

Connector

Terminal

E18

13

B42

1

Existed