Nissan Altima HL32 Hybrid. Manual - part 350

EC-384

< COMPONENT DIAGNOSIS >

[QR25DE]

COOLING FAN

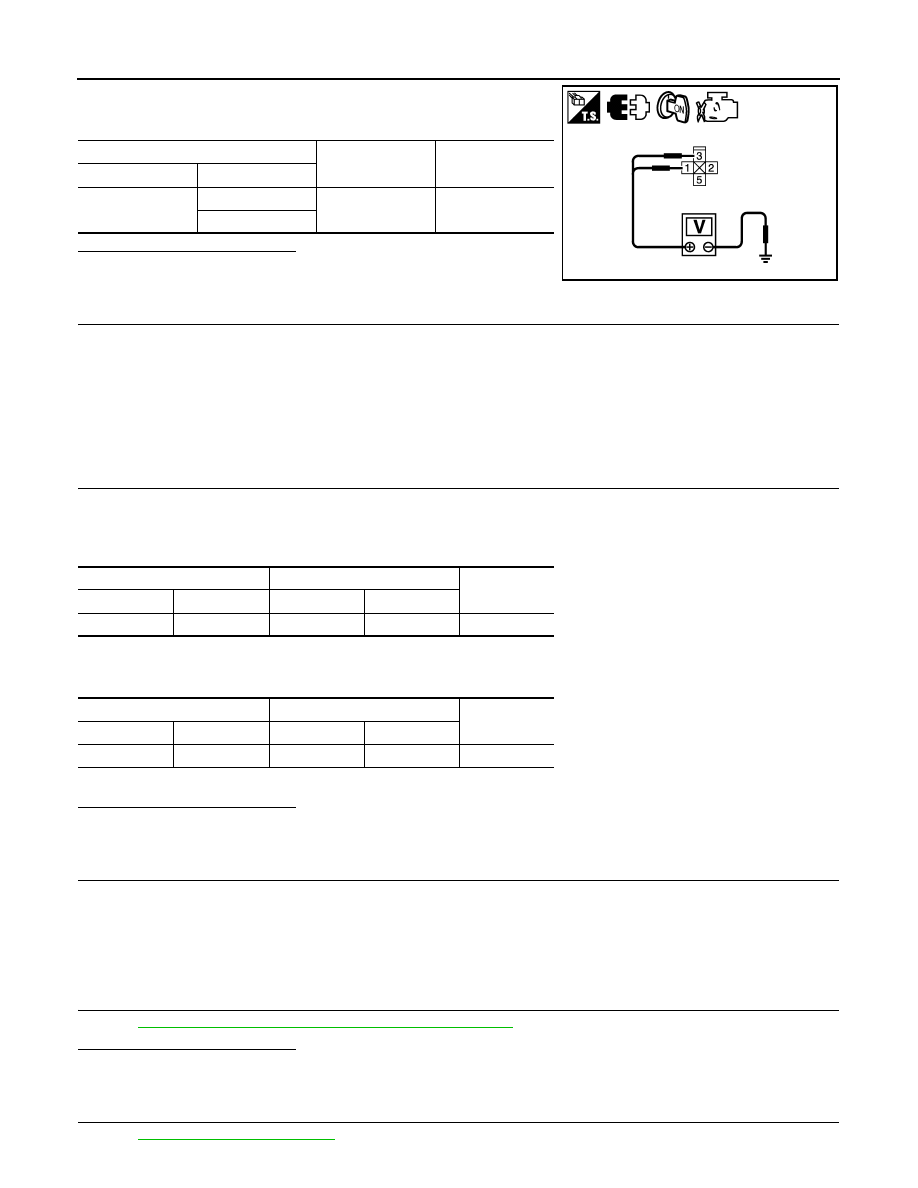

4. Check the voltage between cooling fan relay harness connector

and ground.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 8.

8.

DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R harness connector E18

• 50A fusible link (letter O)

• Harness for open or short between cooling fan relay-1 and fuse

• Harness for open or short between cooling fan relay-1 and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.

CHECK COOLING FAN CONTROL MODULE POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E17.

3. Check the continuity between cooling fan relay-1 harness connector and IPDM E/R harness connector.

4. Check the continuity between cooling fan relay harness connector and cooling fan control module harness

connector.

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> GO TO 10.

10.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E81, E207

• Harness for open or short between cooling fan relay-1 and cooling fan control module

>> Repair open circuit or short to ground or short to power in harness or connectors.

11.

CHECK COOLING FAN RELAY-1

EC-385, "Component Inspection (Cooling Fan Relay)"

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Replace cooling fan relay-1.

12.

CHECK INTERMITTENT INCIDENT

Perform

GI-42, "Intermittent Incident"

.

Cooling fan relay-1

Ground

Voltage

Connector

Terminal

E82

1

Ground

Battery voltage

3

JMBIA1646ZZ

Cooling fan relay-1

IPDM E/R

Continuity

Connector

Terminal

Connector

Terminal

E82

2

E17

42

Existed

Cooling fan relay-1

Cooling fan control module

Continuity

Connector

Terminal

Connector

Terminal

E82

5

E231

3

Existed