Nissan Altima HL32 Hybrid. Manual - part 346

EC-368

< COMPONENT DIAGNOSIS >

[QR25DE]

P2135 TP SENSOR

NO

>> Repair or replace ground connection.

2.

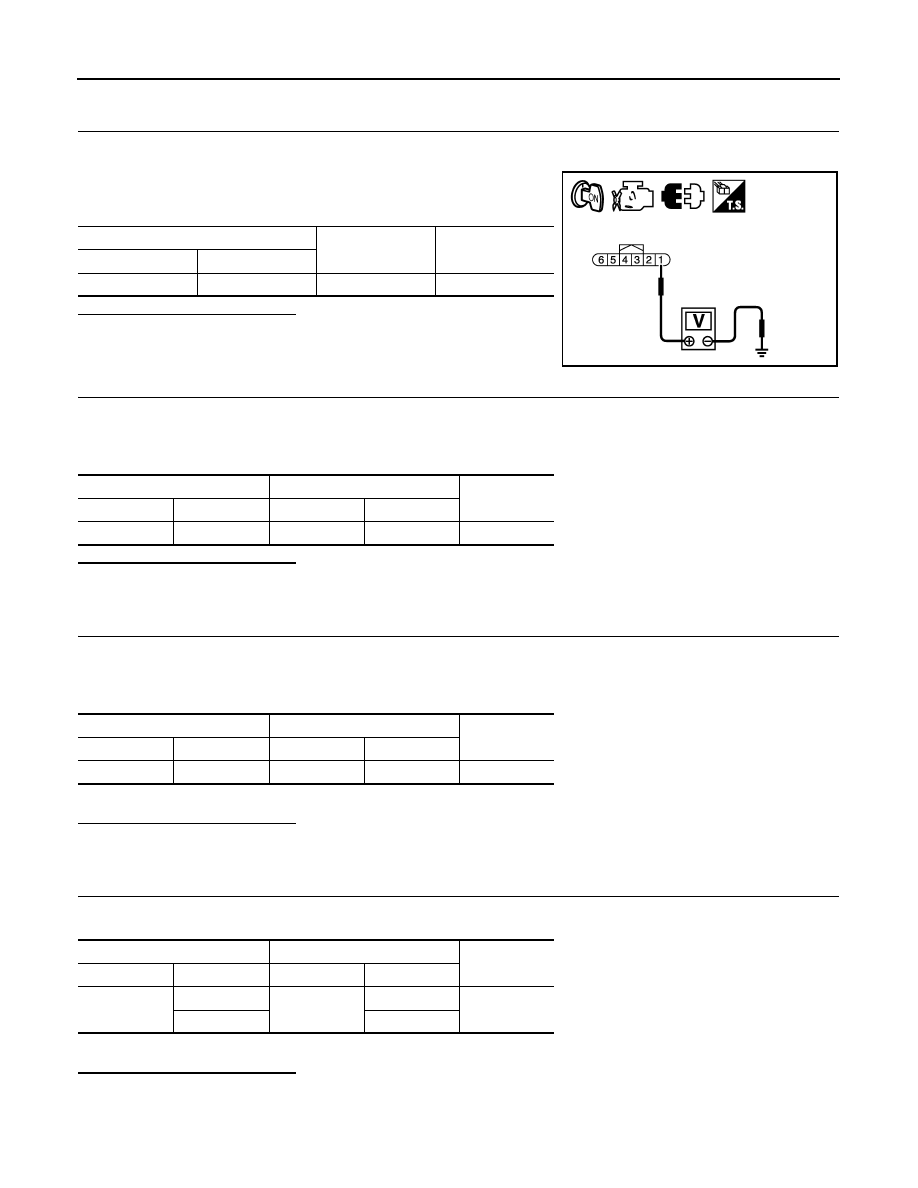

CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT-I

1. Disconnect electric throttle control actuator harness connector.

2. Turn ignition switch ON.

3. Check the voltage between electric throttle control actuator har-

ness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit.

4.

CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ground.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between electric throttle control actuator harness connector and ground.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

Electric throttle control actuator

Ground

Voltage

Connector

Terminal

F57

1

Ground

Approx. 5V

JMBIA1584ZZ

Electric throttle control actuator

ECM

Continuity

Connector

Terminal

Connector

Terminal

F57

1

F13

47

Existed

Electric throttle control actuator

ECM

Continuity

Connector

Terminal

Connector

Terminal

F57

4

F13

36

Existed

Electric throttle control actuator

ECM

Continuity

Connector

Terminal

Connector

Terminal

F57

2

F13

37

Existed

3

38