Nissan Altima HL32 Hybrid. Manual - part 311

EC-228

< COMPONENT DIAGNOSIS >

[QR25DE]

P0172 FUEL INJECTION SYSTEM FUNCTION

P0172 FUEL INJECTION SYSTEM FUNCTION

DTC Logic

INFOID:0000000004211463

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the A/F sensors 1. The ECM calcu-

lates the necessary compensation to correct the offset between the actual and the theoretical ratios.

In case the amount of the compensation value is extremely large (The actual mixture ratio is too rich.), the

ECM judges the condition as the fuel injection system malfunction and lights up the MIL (2 trip detection logic).

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE-II

1. Clear the mixture ratio self-learning value. Refer to

EC-18, "MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement"

.

2. Activate “INSPECTION MODE 1” (

) to start engine, and let engine idle for at least 5 minutes.

3. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> GO TO 3.

3.

PERFORM DTC CONFIRMATION PROCEDURE-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON (READY).

3. Maintain the following conditions for at least 10 consecutive minutes. Hold the accelerator pedal as steady

as possible.

CAUTION:

Always drive vehicle at a safe speed.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

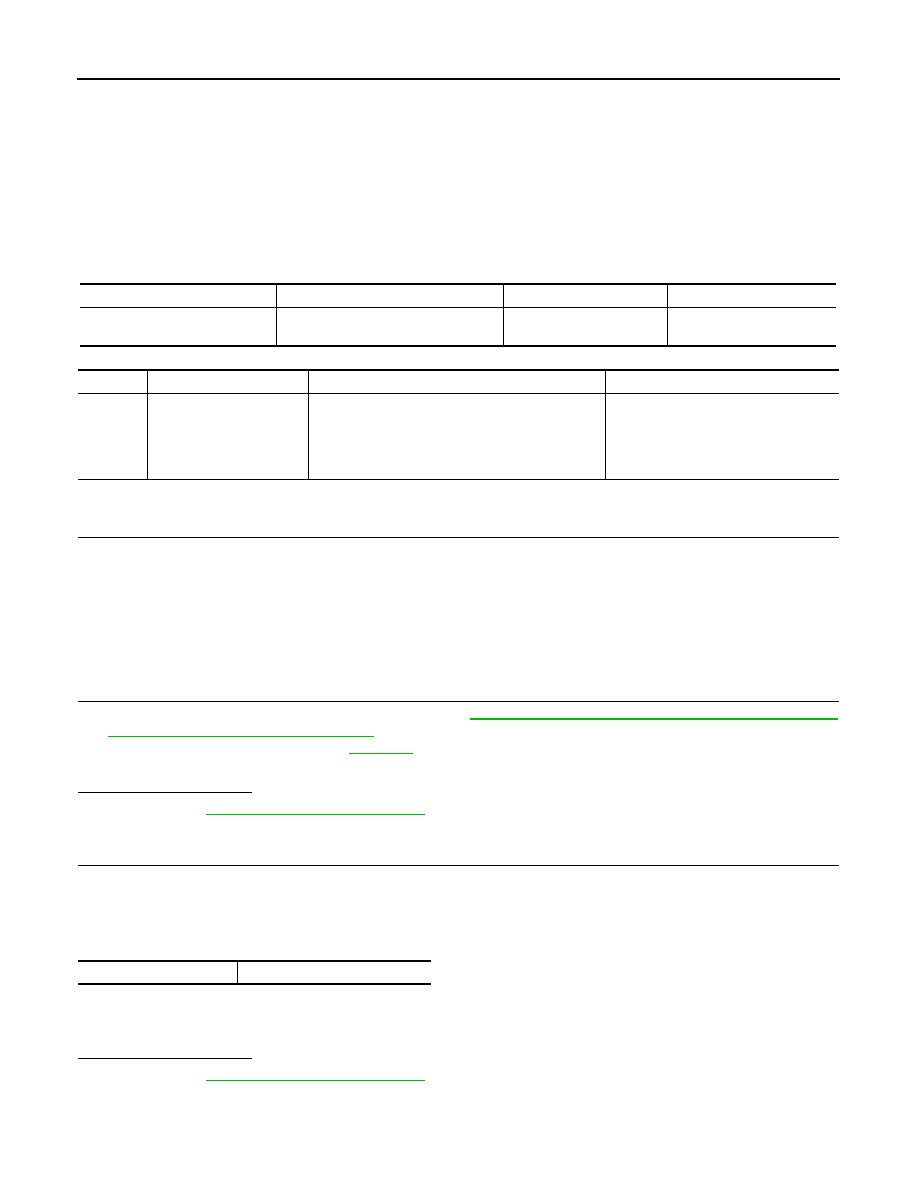

Sensor

Input signal to ECM

ECM function

Actuator

A/F sensor 1

Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Fuel injection control

Fuel injector

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0172

Fuel injection system too

rich

• Fuel injection system does not operate properly.

• The amount of mixture ratio compensation is too

large. (The mixture ratio is too rich.)

• A/F sensor 1

• Fuel injector

• Exhaust gas leaks

• Incorrect fuel pressure

• Mass air flow sensor

VECL SPEED SE

80 - 120 km/h (50 mph - 75 mph)