Content .. 1122 1123 1124 1125 ..

Nissan Altima HL32 Hybrid. Manual - part 1124

TIRE PRESSURE RECEIVER

WT-61

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

ON-VEHICLE REPAIR

TIRE PRESSURE RECEIVER

Removal and Installation

INFOID:0000000004212532

REMOVAL

1. Remove instrument lower cover (LH). Refer to

IP-12, "Removal and Installation"

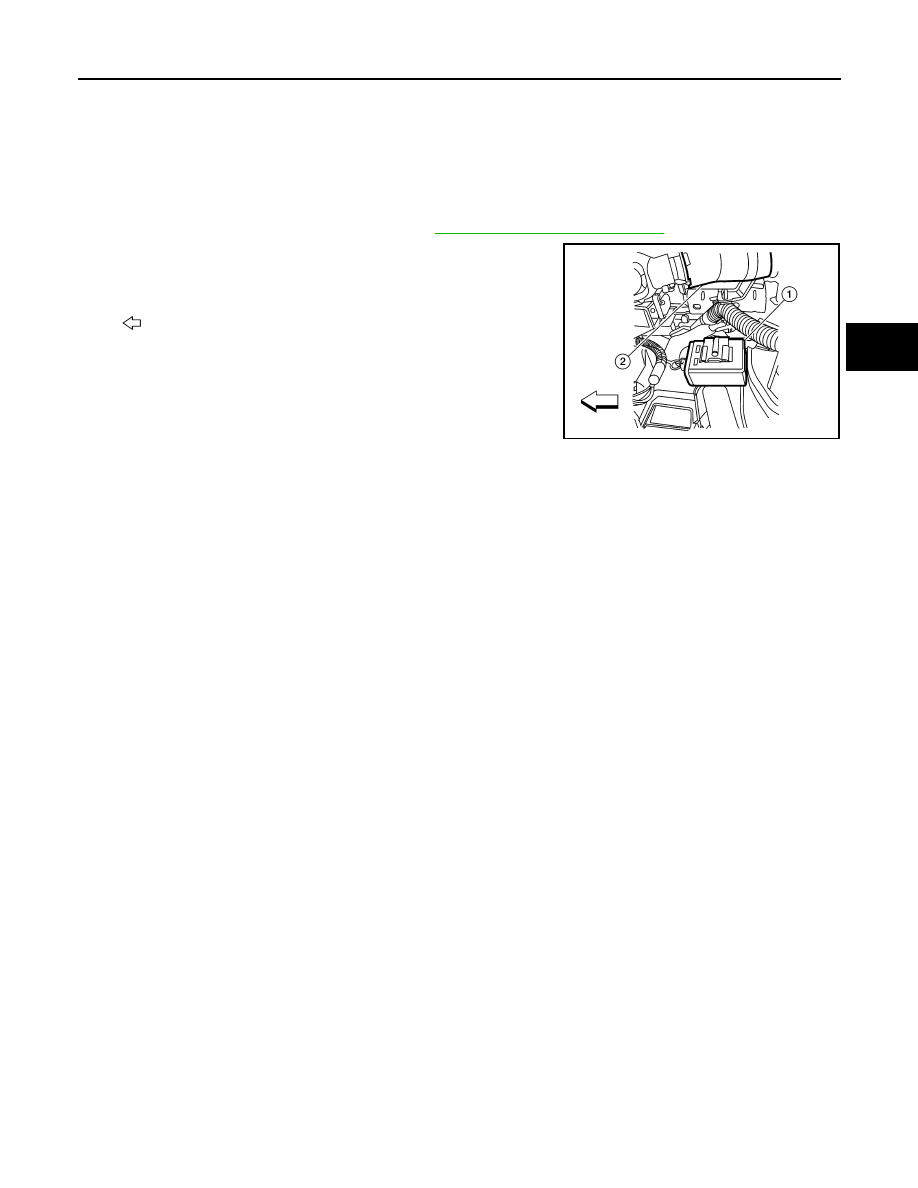

2. Locate tire pressure receiver (1) to the right of the steering col-

umn (2) and disconnect the tire pressure receiver connector.

3. Remove the tire pressure receiver (1) from bracket using a suit-

able tool to release the bracket.

•

: Vehicle front

INSTALLATION

Installation is in the reverse order of removal.

ALEIA0011ZZ