Nissan Frontier. Manual - part 817

WHEEL HUB

FAX-5

< PERIODIC MAINTENANCE >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

PERIODIC MAINTENANCE

WHEEL HUB

On-Vehicle Inspection and Service

INFOID:0000000009480028

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are normal.

WHEEL BEARING INSPECTION

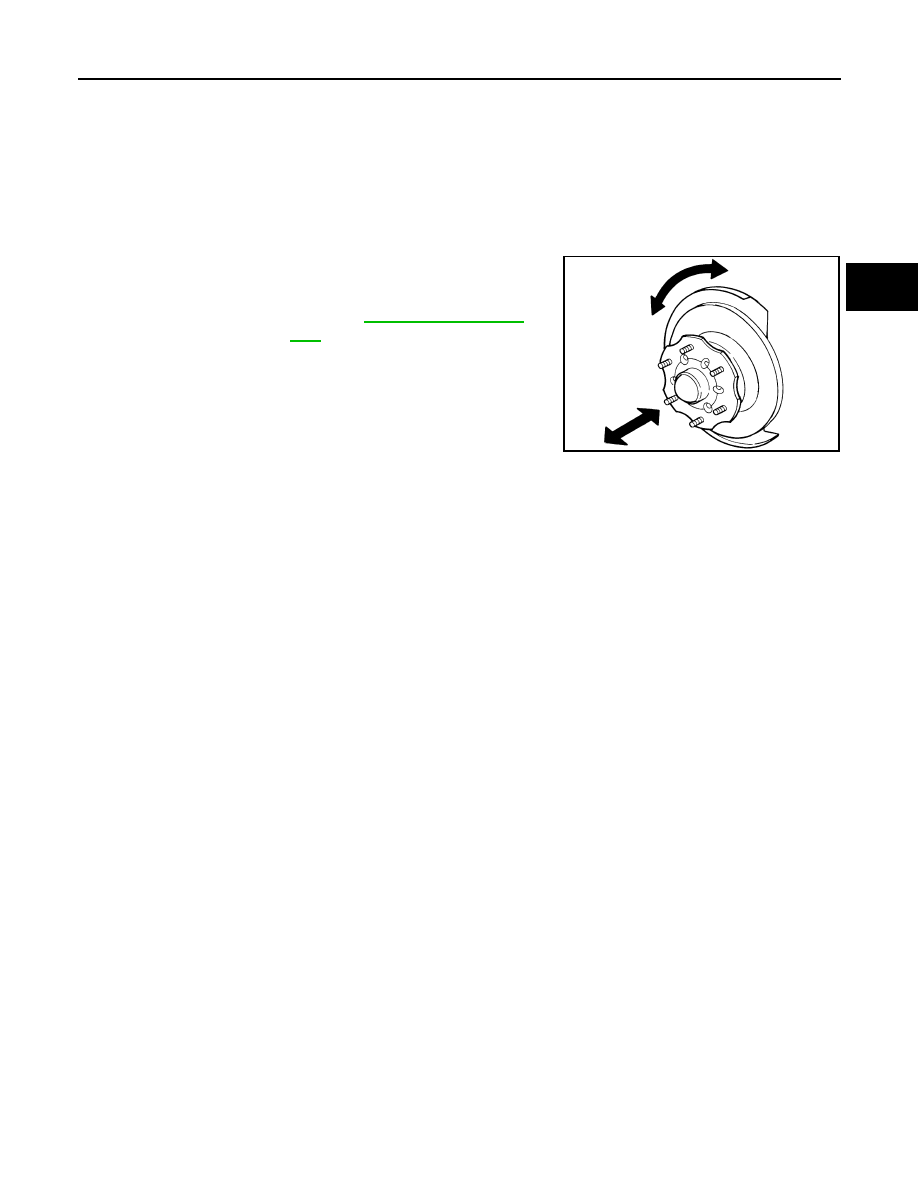

• Move wheel hub in the axial direction by hand. Make sure there is

no looseness of wheel bearing.

• Rotate wheel hub and make sure there is no unusual noise or

other irregular conditions. If there are any irregular conditions,

replace wheel hub and bearing assembly.

Axial end play limit : Refer to

.

SMA571A