Nissan Frontier. Manual - part 415

P0171 FUEL INJECTION SYSTEM FUNCTION

EC-231

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Check the following.

• Fuel pump and circuit (Refer to

.)

• Fuel pressure regulator (Refer to

• Fuel lines

• Fuel filter for clogging

>> Repair or replace.

6.

CHECK MASS AIR FLOW SENSOR

With CONSULT

1. Install all removed parts.

2. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT.

With GST

1. Install all removed parts.

2. Check mass air flow sensor signal in Service $01 with GST.

OK or NG

OK

>> GO TO 7.

NG

>> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

grounds. Refer to

EC-168, "Component Description"

.

7.

CHECK FUNCTION OF FUEL INJECTOR

With CONSULT

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT.

3. Make sure that each circuit produces a momentary engine speed drop.

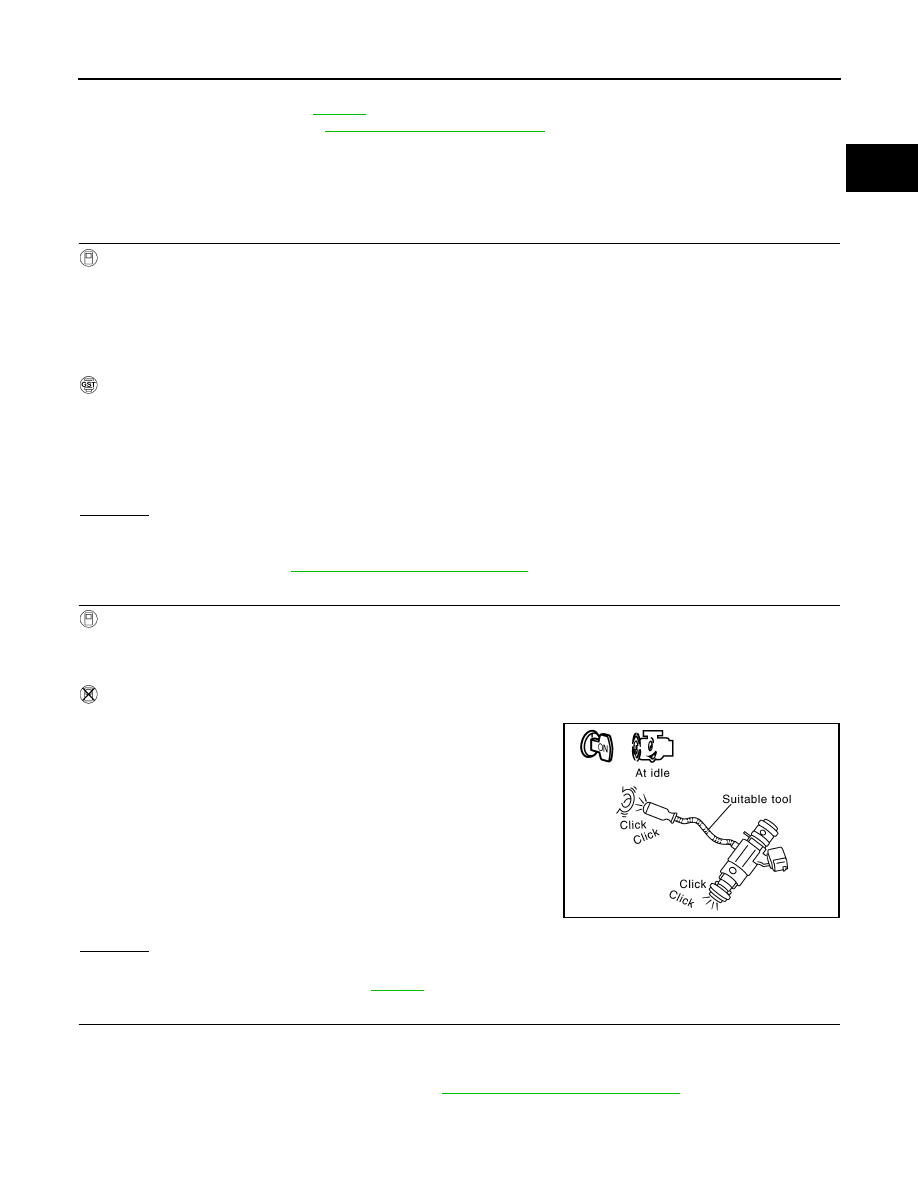

Without CONSULT

1. Start engine.

2. Listen to each fuel injector operating sound.

OK or NG

OK

>> GO TO 8.

NG

>> Perform trouble diagnosis for

.

8.

CHECK FUEL INJECTOR

1. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

2. Turn ignition switch OFF.

3. Disconnect fuel injector harness connectors.

4. Remove fuel injector gallery assembly. Refer to

EM-39, "Removal and Installation"

Keep fuel hose and all fuel injectors connected to fuel injector gallery.

The fuel injector harness connectors should remain connected.

At idling:

1.0 - 4.0 g/s

At 2,500 rpm:

4.0 - 12.0 g/s

At idling:

1.0 - 4.0 g/s

At 2,500 rpm:

4.0 - 12.0 g/s

Clicking noise should be heard.

PBIB1986E