Nissan Frontier. Manual - part 318

DLN-174

< UNIT REMOVAL AND INSTALLATION >

[PROPELLER SHAFT: 3S1330-2BJ100]

REAR PROPELLER SHAFT

UNIT REMOVAL AND INSTALLATION

REAR PROPELLER SHAFT

Removal and Installation

INFOID:0000000009479764

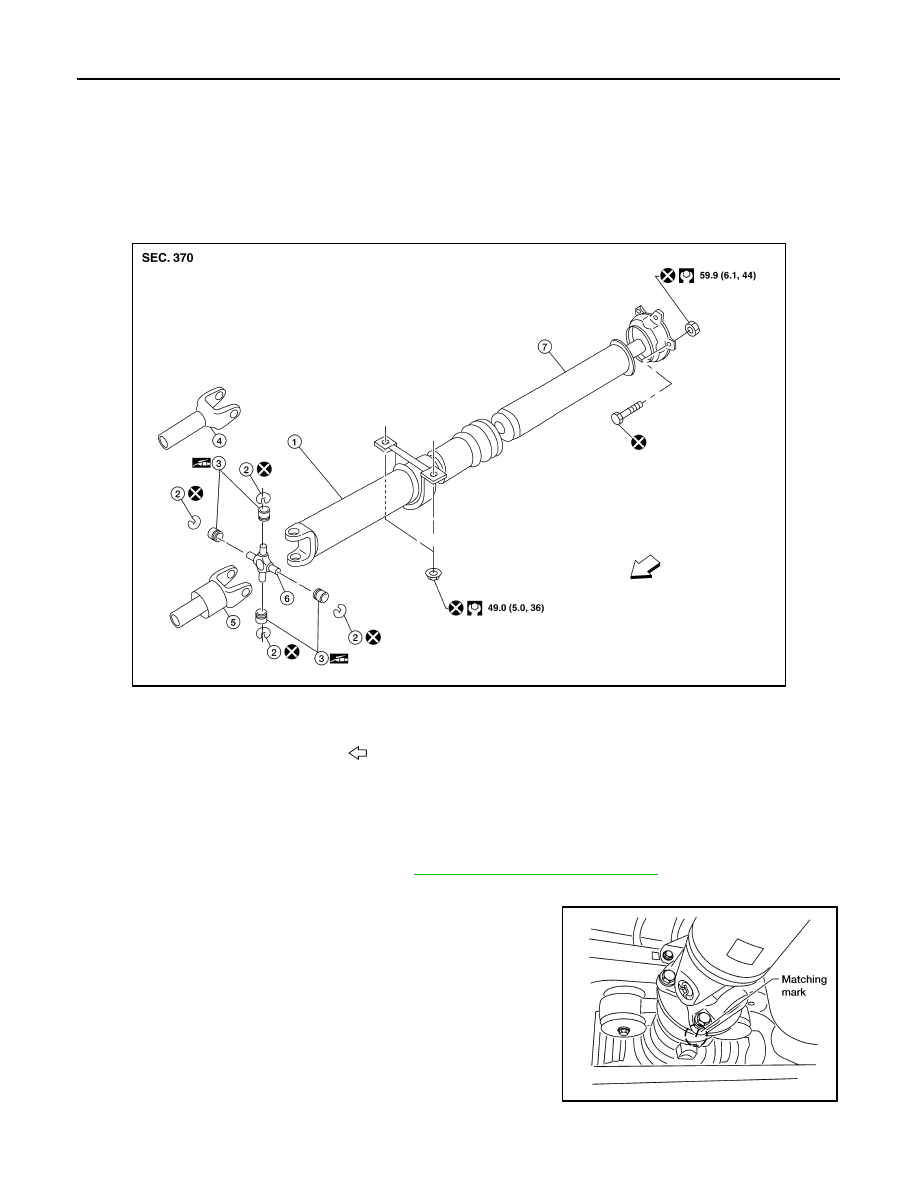

COMPONENTS

Model 3S1330–2BJ100

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove under cover (if equipped). Refer to

EXT-15, "Removal and Installation"

.

2. Put the transmission in neutral and release the parking brake.

3. Put matching marks on the rear propeller shaft flange yoke and

the rear final drive companion flange as shown.

CAUTION:

For matching marks, use paint. Do not damage the rear pro-

peller shaft flange yoke or the companion flange.

4. Remove the bolts, then remove the propeller shaft from the rear

final drive and transmission or transfer.

INSPECTION

AWDIA0689GB

1.

Propeller shaft (1st shaft)

2.

Snap ring

3.

Journal bearing

4.

Sleeve yoke (4WD)

5.

Sleeve yoke (2WD)

6.

Journal

7.

Propeller shaft (2nd shaft)

Front

WDIA0049E