Nissan Frontier. Manual - part 319

DLN-178

< UNIT DISASSEMBLY AND ASSEMBLY >

[PROPELLER SHAFT: 3S1330-2BJ100]

REAR PROPELLER SHAFT

4. Make sure that the journal moves smoothly and is below the

joint flex effort specification. Refer to

.

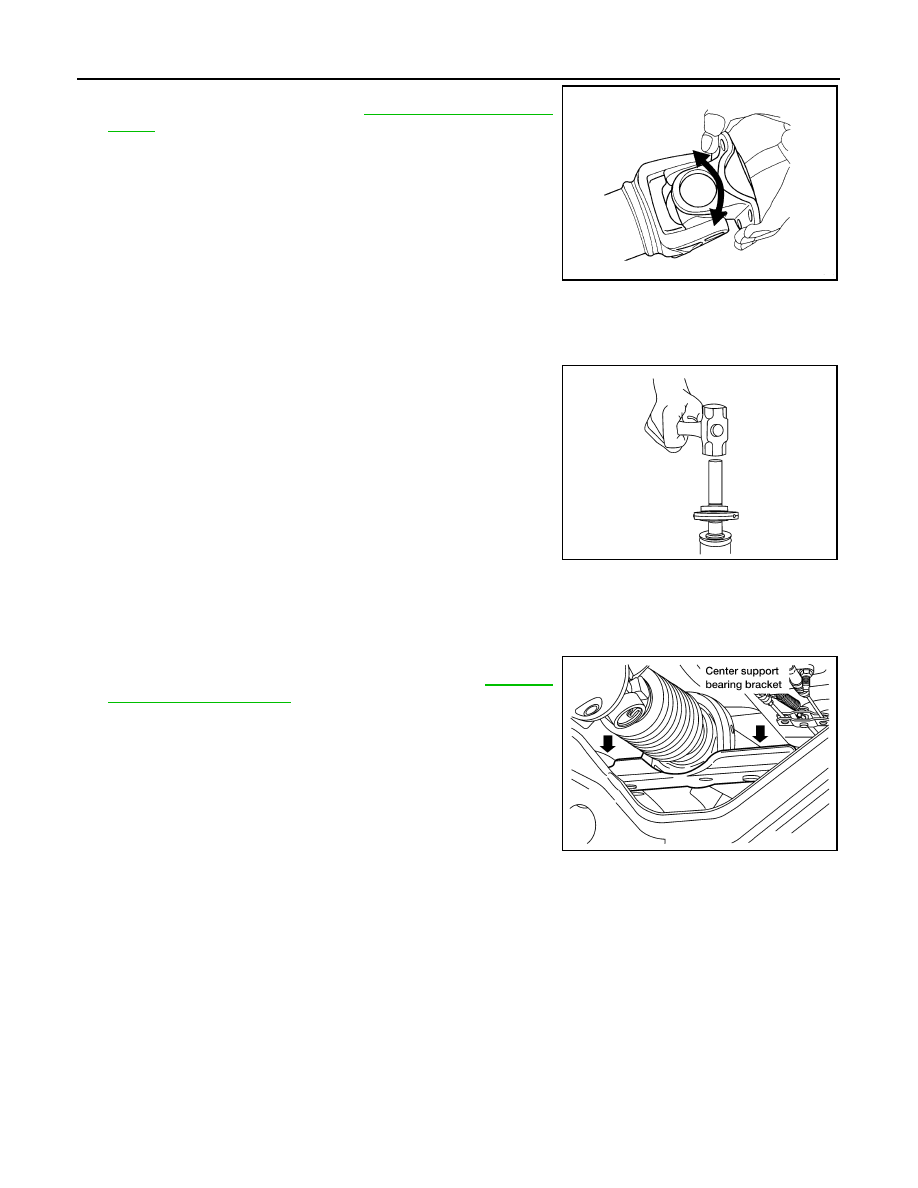

Center Support Bearing

1. Apply a thin coat of multi-purpose grease to both the propeller shaft tube and the inside surface of the

center support bearing.

2. Install the center support bearing on the propeller shaft tube

using a suitable pipe pressing on the inner race.

3. Install a new clamp over the boot on the slip yoke.

4. Align the matching marks and install the slip yoke on the propeller shaft tube.

5. Clean the surfaces and position the boot over the propeller shaft tube and tighten the clamp.

6. Install the center support bearing bracket, then install the rear

propeller shaft assembly in the vehicle. Refer to

LDIA0119E

LDIA0153E

WDIA0066E