Content .. 1277 1278 1279 1280 ..

Nissan Frontier. Manual - part 1279

DISASSEMBLY

TM-327

< UNIT DISASSEMBLY AND ASSEMBLY >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

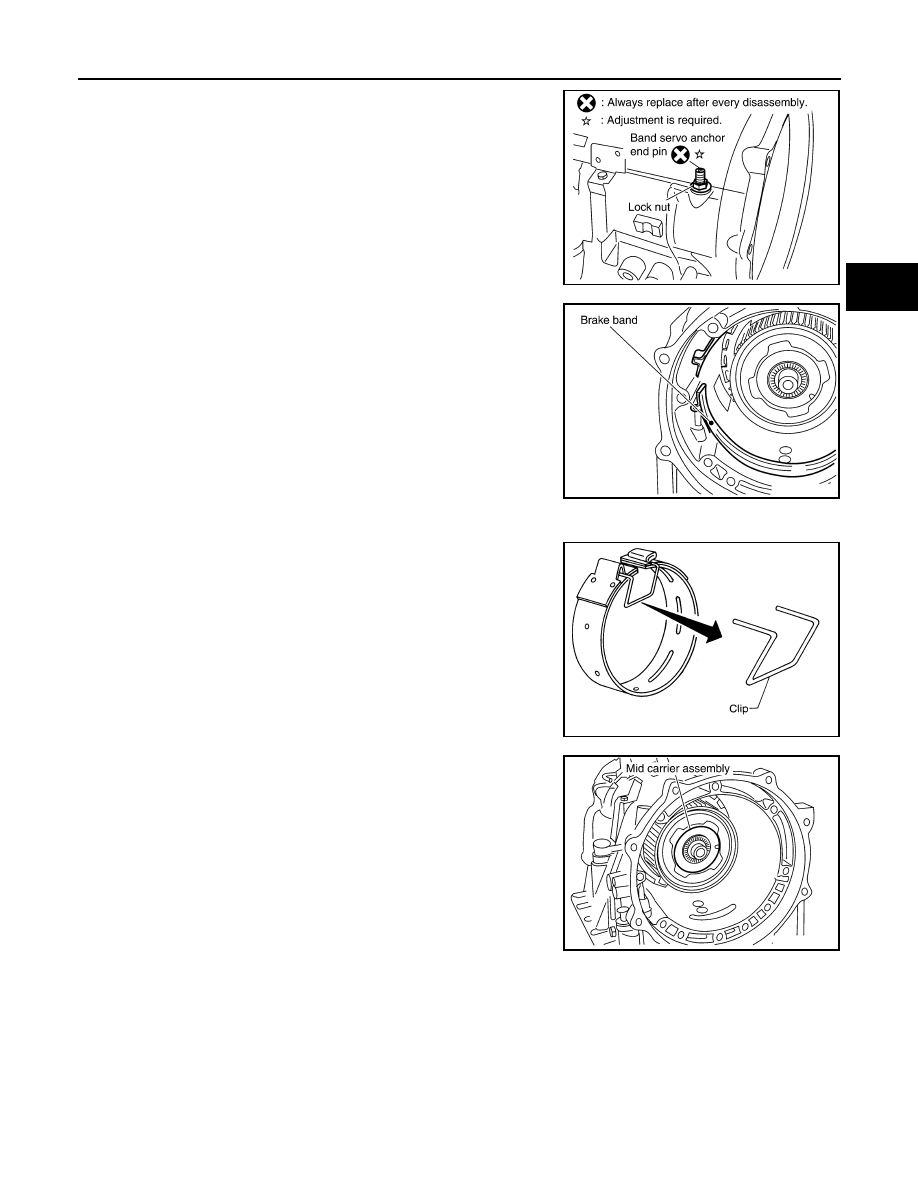

14. Loosen lock nut and remove band servo anchor end pin from

transmission case.

15. Remove brake band from transmission case.

CAUTION:

• To prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown.

• Check brake band facing for damage, cracks, wear or

burns.

16. Remove mid carrier assembly and rear carrier assembly as a

unit.

SCIA6512E

SCIA2580E

SAT655

SCIA5017E