Nissan Sentra. Manual - part 913

TM-288

< SERVICE DATA AND SPECIFICATIONS (SDS)

[CVT: RE0F11A]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

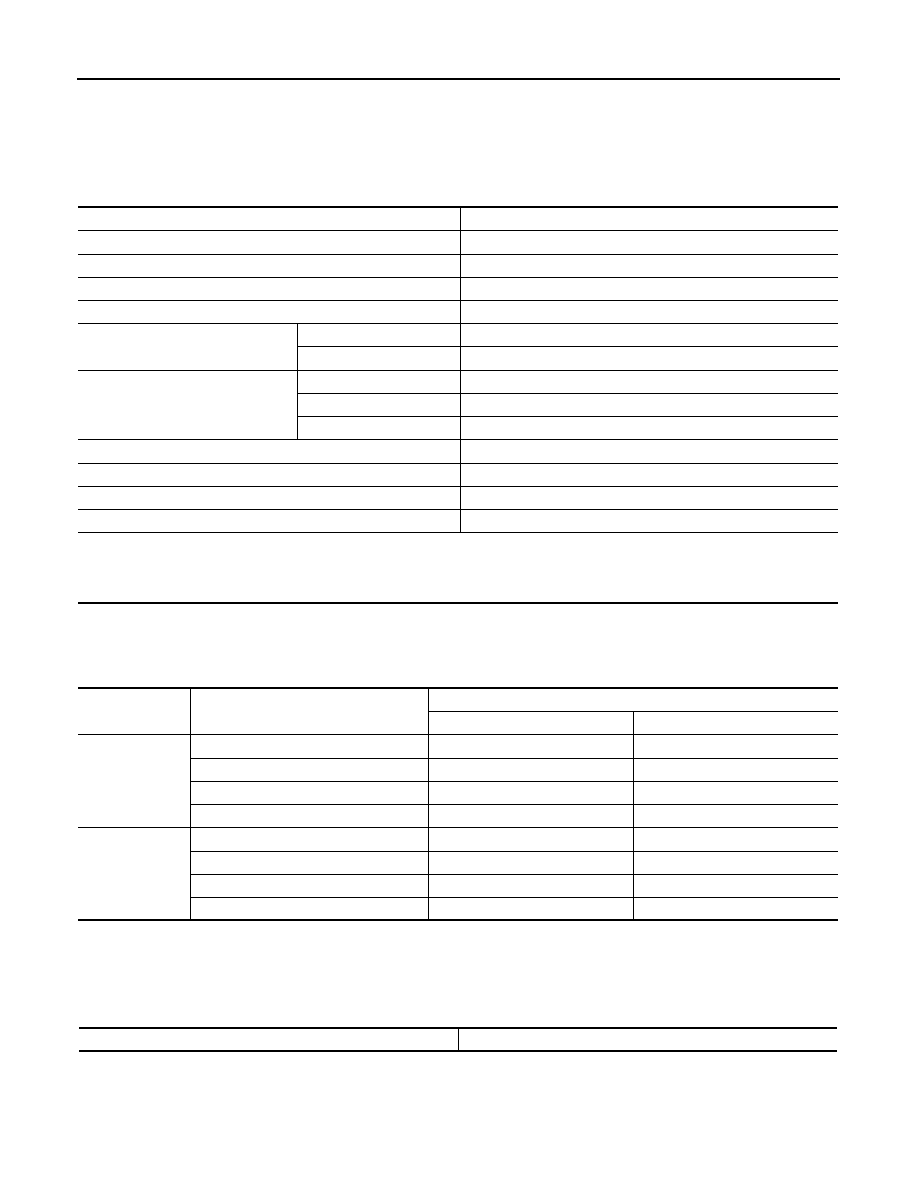

General Specification

INFOID:0000000009759541

*: The CVT fluid capacity is the reference value.

Shift Characteristics

INFOID:0000000009759542

Unit: rpm

NOTE:

Lock-up is engaged at the vehicle speed of approximately 10 km/h (11 MPH) to 90 km/h (56 MPH).

Stall Speed

INFOID:0000000009759543

Unit: rpm

Engine model

MRA8DE

Drive type

2WD

Transaxle model

RE0F11A

Transaxle model code number

X427A

Stall torque ratio

1.91 : 1

Pulley ratio

Forward

2.200 – 0.550

Reverse

2.200

Auxiliary gearbox gear ratio

1GR

1.821

2GR

1.000

Reverse

1.714

Counter gear

0.906

Final drive

3.882

Recommended fluid

Genuine NISSAN CVT Fluid NS-3

Fluid capacity liter (US qt, lmp qt)

Approx. 6.9 (7-1/4, 6-1/8)*

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-3. Never mix with other fluid.

• Use only Genuine NISSAN CVT Fluid NS-3. Using transmission fluid other than Genuine NISSAN CVT Fluid NS-3 will dam-

age the CVT, which is not covered by the warranty.

Throttle position

Shift pattern

CVT input speed

At 40 km/h (25 MPH)

At 60 km/h (37 MPH)

2/8

“D” position (OD ON)

1,500 – 2,600

1,700 – 3,000

“D” position (OD OFF)

2,300 – 3,100

2,700 – 3,500

“L” position

3,000 – 3,800

3,500 – 4,300

ECO mode

1,500 – 2,300

1,700 – 2,500

8/8

“D” position (OD ON)

3,900 – 5,000

4,500 – 6,100

“D” position (OD OFF)

3,900 – 5,000

4,500 – 6,100

“L” position

3,900 – 5,000

4,500 – 6,100

ECO mode

3,900 – 4,700

4,500 – 5,300

Stall speed

2,690 – 3,200