Nissan Sentra. Manual - part 912

TM-284

< UNIT REMOVAL AND INSTALLATION >

[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

NOTE:

• When removing components such as hoses, tubes/line, etc., cap or plug openings to prevent fluid from spill-

ing.

• When replacing the TCM and transaxle assembly as a set, replace the transaxle assembly first and then

replace the TCM. Refer to

.

1. Remove the engine and transaxle assembly. Refer to

EM-82, "M/T : Removal and Installation"

(MT) or

EM-86, "CVT : Removal and Installation"

(CVT).

2. Disconnect the connectors and harnesses.

• For CVT unit harness connector, refer to

TM-69, "Removal and Installation Procedure for CVT Unit Con-

• Transmission position switch harness connector

• Primary pulley speed sensor harness connector

• Secondary pulley speed sensor harness connector

• Output speed sensor harness connector

• Ground

3. Rotate the crankshaft and remove the nuts that secure the drive plate to the torque converter from the sta-

tor motor mount.

CAUTION:

Rotate crankshaft clockwise (as viewed from the front of the engine).

4. Remove the bolts (engine to transaxle) that fasten the transaxle

assembly and engine assembly.

5. Remove transmission bracket.

6. Lift the transaxle from the front suspension member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transaxle you must make sure any dowels are installed correctly during

re-assembly

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings or copper sealing washers.

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the nuts for the torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to

.

• After converter is installed to drive plate, rotate crankshaft several turns to check that CVT rotates

freely without binding.

• When installing the CVT to the engine, align the matching mark on the drive plate with the matching

mark on the torque converter.

NOTE:

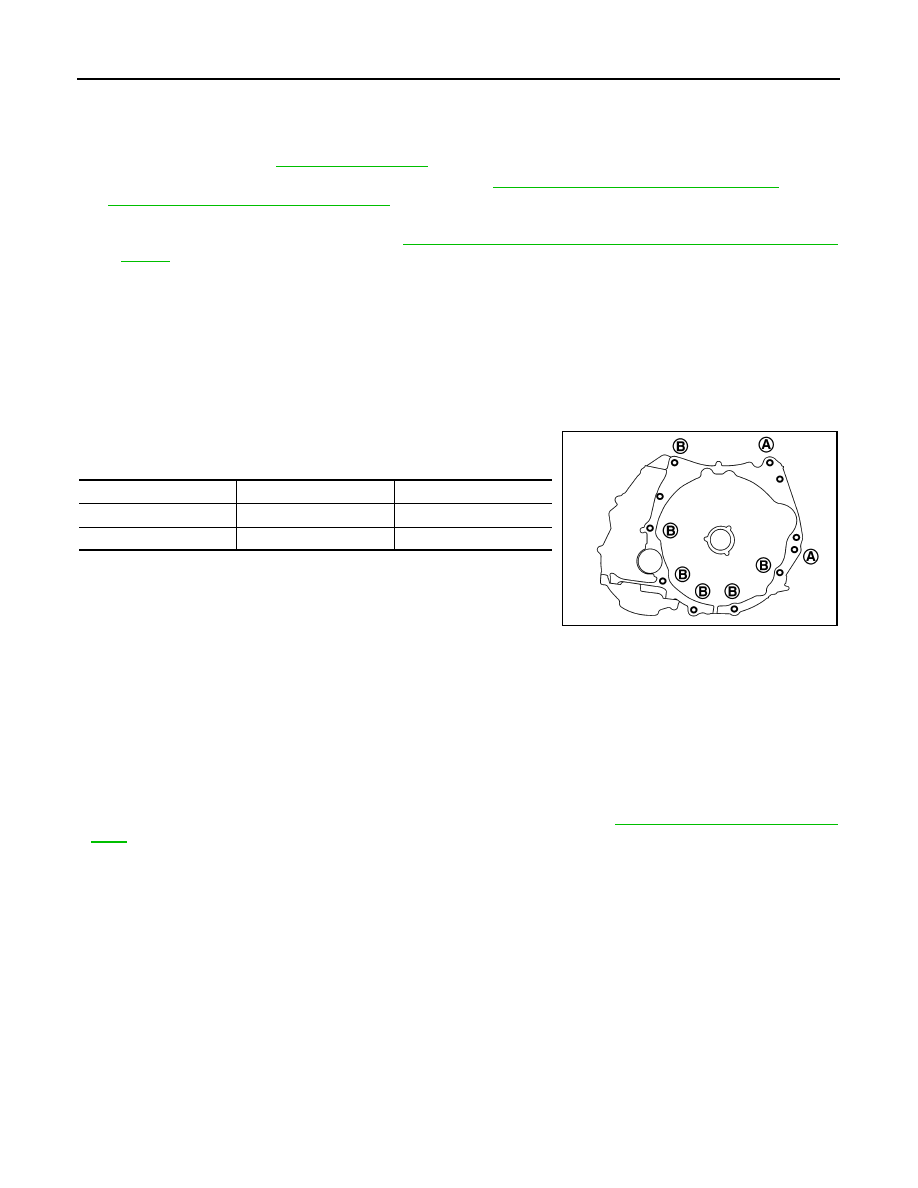

Install the transaxle assembly and engine assembly mounting bolts according to the following standards.

Bolt position

(A)

(B)

Direction of insertion

Transaxle to engine

Engine to transaxle

Quantity

2

6

JSDIA3588ZZ