Nissan Sentra. Manual - part 630

CHASSIS AND BODY MAINTENANCE

MA-23

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

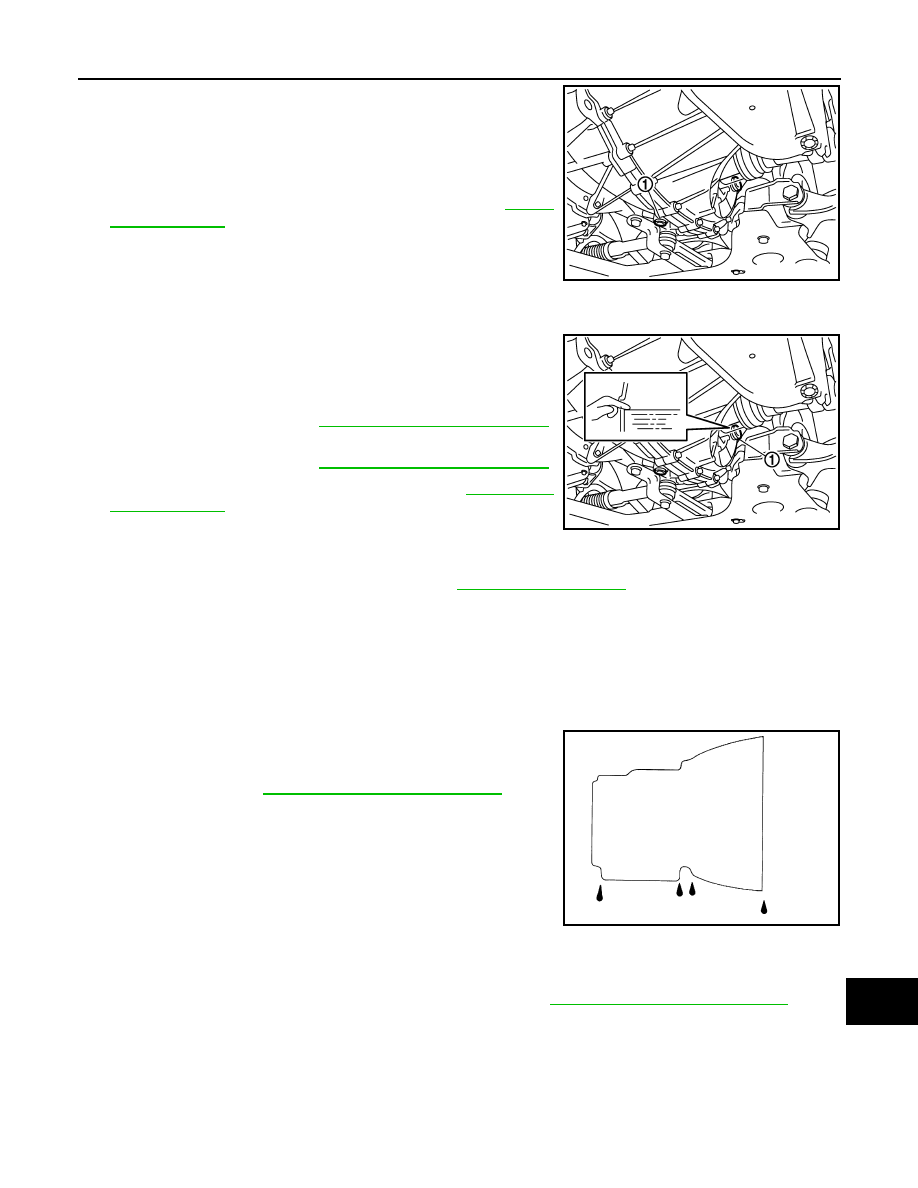

2. Stop engine. Remove drain plug (1) and gasket, using a suitable

tool and then drain gear oil.

3. Set a gasket on drain plug and install it to clutch housing, using

a suitable tool.

CAUTION:

Do not reuse gasket.

4. Tighten drain plug to the specified torque. Refer to

CAUTION:

Do not overtighten the filler plug as this could cause the

transaxle case to crack.

M/T OIL : Refilling

INFOID:0000000009756198

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at

filler plug mounting hole as shown.

3. After refilling gear oil, check the oil level. Refer to

.

4. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Do not reuse gasket.

5. Tighten filler plug to the specified torque. Refer to

CAUTION:

Do not overtighten the filler plug as this could cause the transaxle case to crack.

CVT FLUID

CVT FLUID : Inspection

INFOID:0000000009756199

FLUID LEAKAGE

• Check transaxle surrounding area (oil seal and plug etc.) for fluid

leakage.

• If anything is found, repair or replace damaged parts and adjust

CVT fluid level. Refer to

MA-25, "CVT FLUID : Adjustment"

CVT FLUID : Replacement

INFOID:0000000009756200

CAUTION:

• Use only recommended CVT fluid. Using transmission fluid other than recommended CVT fluid will

damage the CVT, which is not covered by the warranty.

• Always use shop paper. Do not use shop cloth.

• Replace a drain plug gasket with new ones at the final stage of the operation when installing.

• Use caution when looking into the drain hole as there is a risk of dripping fluid entering the eye.

• After replacement, always perform CVT fluid leakage check.

SCIA7622E

Oil grade and

viscosity

: Refer to

MA-11, "Fluids and Lubricants"

.

Oil capacity

: Refer to

MA-11, "Fluids and Lubricants"

.

SCIA7623E

SMA146B

Recommended CVT fluid and fluid capacity

: Refer to

TM-288, "General Specification"

.