Nissan Sentra. Manual - part 628

ENGINE MAINTENANCE

MA-15

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

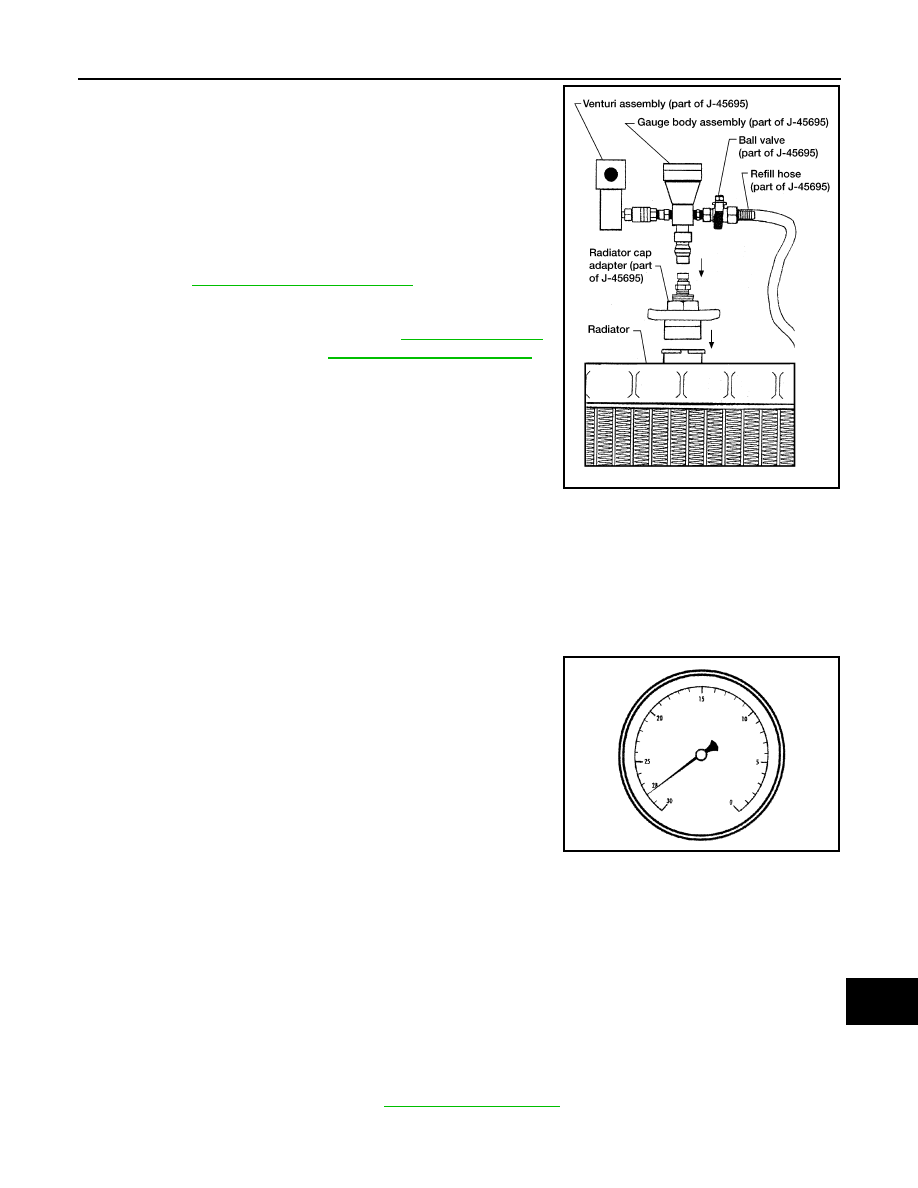

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the engine coolant mixture container

that is placed at floor level. Make sure the ball valve is in the

closed position.

• Use recommended engine coolant or equivalent.

Refer to

MA-11, "Fluids and Lubricants"

(United States and

Canada).

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog the cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must

be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open

the ball valve on the refill hose slightly. Engine coolant will be visible rising in the refill hose. Once the refill

hose is full of engine coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches

of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the engine coolant container (with the refill hose inserted) at the same level as the top of the radia-

tor. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling sys-

tem. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant container to get too low when filling, to avoid air from being drawn

into the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

13. Install the engine under cover. Refer to

FLUSHING COOLING SYSTEM

Tool number

: KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to

.

Compressed air

supply pressure

: 549 - 824 kPa (5.6 - 8.4 kg/cm

2

,

80 - 119 psi)

LLIA0058E

Altitude above sea level

Vacuum gauge reading

0 - 100 m (328 ft)

: 28 inches of vacuum

300 m (984 ft)

: 27 inches of vacuum

500 m (1,641 ft)

: 26 inches of vacuum

1,000 m (3,281 ft)

: 24 - 25 inches of vacuum

LLIA0057E